Moisture-Proof Design of Smart PDUs in Underground Telecom Cabinets: Enhanced Electrical Safety in High-Humidity Environments

You face real challenges when moisture builds up in underground telecom cabinets. Water can damage equipment and create hazards for electrical safety. ESTEL’s smart power distribution unit uses moisture-resistant materials, advanced sealing, and a built-in dehumidifying function. You can monitor conditions in real time and react quickly to changes. Meeting strict safety standards protects your telecom infrastructure from costly failures.

Key Takeaways

Moisture can damage telecom equipment and create electrical hazards. Use moisture-proof smart power distribution units to protect your infrastructure.

Select power distribution units with advanced sealing and moisture-resistant materials. This choice extends equipment lifespan and reduces maintenance costs.

Integrate dehumidifying features and real-time monitoring systems. These tools help manage humidity levels and prevent condensation inside cabinets.

Follow best practices for installation and maintenance. Regular inspections and proper cable management enhance reliability and efficiency in underground environments.

Ensure compliance with safety standards like ISO9001 and UL. Meeting these standards guarantees safe operation in high-humidity conditions.

Moisture Risks in Telecom Cabinets

Sources of Moisture Underground

You often find that underground environments create unique challenges for outdoor telecom cabinets. Water can seep into the ground from rain, flooding, or high water tables. Humid air trapped in confined spaces increases the risk of condensation inside each cabinet. In many cases, you see that temperature changes cause warm air to meet cooler cabinet surfaces, which leads to moisture buildup. Outdoor telecom cabinets in coastal or tropical regions face even higher humidity, making moisture control a constant concern.

Impact on Power Distribution Units

When moisture enters outdoor telecom cabinets, it can quickly affect the performance of power distribution units. You may notice condensation forming on internal components. This moisture can corrode metal parts and damage sensitive electronics. Over time, corrosion weakens connections and reduces the lifespan of your equipment. Outdoor telecom cabinets with climate control features help prevent moisture buildup by blocking external threats and managing internal humidity. Active cooling systems and integrated air conditioning maintain stable humidity levels, which eliminates the conditions that cause condensation. You protect your telecom cabinet and its power distribution unit by keeping humidity in check.

Note: Properly sealed outdoor telecom cabinets provide dual protection. They keep out external water and manage internal humidity, which is especially important for telecom sites in challenging environments.

Common Electrical Failures

Moisture inside outdoor telecom cabinets often leads to electrical hazards. You might encounter short circuits when water bridges connections between components. Corrosion can cause intermittent faults or complete failure of power distribution units. In some cases, you see insulation breakdown, which increases the risk of electrical hazards and equipment downtime. Outdoor telecom cabinets that lack moisture-proof features experience more frequent failures and higher maintenance costs. By understanding these risks, you can take steps to protect your telecom infrastructure and ensure reliable operation.

Moisture-Proof Design Principles for Smart Power Distribution Units

Material Selection and Sealing

You need a smart power distribution unit that can withstand harsh underground conditions. The right material selection and sealing techniques play a critical role in protecting your equipment. ESTEL uses rugged metal bodies and moisture-resistant materials to prevent corrosion and extend the lifespan of each power distribution unit. Advanced sealing methods block water, dust, and other contaminants from entering the cabinet.

Here is a table showing how different sealing techniques work to keep moisture out:

Sealing Technique | Description |

|---|---|

360° EMC/EMP shielding gaskets | Provide complete sealing around the enclosure, blocking water, dust, and electromagnetic interference. |

Silicone gaskets | Effective for environmental sealing, withstands rain, pressure washing, and submersion. |

EMI shielding gaskets | Dual protection against environmental elements and electromagnetic interference. |

EMI/RFI shielding gaskets | Use various materials to achieve high IP ratings, preventing water and dust ingress. |

Hydrophobic coatings | Create a water-repellent surface, preventing corrosion and keeping electronics dry. |

Pressure vents | Balance air pressure to prevent water ingress during temperature changes. |

Conformal coatings | Form a protective barrier over components, blocking moisture, dust, and chemicals. |

PET films | Act as a first shield, enhancing the effectiveness of conformal coatings. |

You see that these sealing solutions help maintain electrical safety and keep your smart power distribution unit operating reliably. When you choose a power distribution unit with robust design and advanced sealing, you reduce the risk of moisture-related failures.

Dehumidifying and Monitoring Features

You can further protect your power distribution unit by using dehumidifying technologies and monitoring systems. ESTEL integrates a dehumidifying function into its smart power distribution unit, which actively removes moisture and prevents condensation. This feature is especially important for underground telecom cabinets where humidity levels can rise quickly.

The table below highlights key dehumidifying and monitoring features:

Feature | Description |

|---|---|

Capacity | 10L/D |

Design | Wall-mounted, compact, rugged metal body |

Purpose | Actively prevents condensation and moisture to protect electrical and telecom equipment |

Smart Integration | RS485 integration for centralized management and monitoring |

Maintenance Alerts | APP notifications for high humidity, pump failure, and filter checks |

Data Analysis | Historical humidity data for maintenance planning and environmental performance validation |

You benefit from real-time monitoring of humidity levels inside your cabinet. Humidity sensors provide continuous data, allowing you to make proactive adjustments and prevent moisture-related damage. You can quickly identify leaks or equipment failures and respond before problems escalate. Adaptive control systems optimize moisture management, keeping your smart power distribution unit in top condition.

Tip: Real-time monitoring and smart integration help you maintain a safe environment for your telecom equipment, reducing downtime and maintenance costs.

Meeting Safety Standards

You must ensure that your smart power distribution unit complies with strict safety standards. These standards guarantee that your equipment can operate safely in high-humidity environments. ESTEL’s power distribution unit meets international safety standards such as ISO9001, UL, CE, and RoHS. You can trust that your equipment has passed rigorous testing for moisture resistance and electrical safety.

ISO9001

UL

CE

RoHS

The IP34D standard, aligned with IEC 60529, sets moisture resistance requirements for electrical cabinets. This standard ensures that your smart power distribution unit can function effectively in outdoor and underground telecom applications. You should look for IP ratings that indicate the level of moisture and dust protection. Compliance with these ratings means your power distribution unit can withstand challenging environmental conditions.

Here is a table summarizing important compliance standards:

Standard | Description |

|---|---|

RoHS | Restriction of Hazardous Substances |

REACH | Registration, Evaluation, Authorisation and Restriction of Chemicals |

EN60529 | Ingress Protection ratings for moisture and dust protection |

You improve reliability and reduce risks when you choose a smart power distribution unit that meets these safety standards. You protect your telecom infrastructure and ensure long-term performance.

Implementation and Maintenance in Telecom Environments

Installation Best Practices

You must approach installation with precision to achieve reliable power and efficient power distribution in underground telecom cabinets. Begin by planning the installation layout to optimize cable management. Organize cables to prevent tangling and allow technicians to access components quickly. You should use modular designs that support future upgrades and active cooling systems for resilience against heat and moisture. During installation, select cabinets with built-in temperature, humidity, power, and intrusion detection. These features enhance monitoring and provide real-time alerts if conditions change.

Follow these steps for a successful installation:

Inspect the cabinet for any signs of moisture before installation.

Arrange cable management trays and ties to keep cables clean and accessible.

Mount the smart power distribution unit securely, ensuring all connections are tight and clean.

Integrate monitoring tools for real-time data on temperature and humidity.

Test all sensors and calibrate them to guarantee accurate readings.

Confirm that surge protection is active to guard against surges.

You improve efficiency and maintain a clean environment by focusing on cable management during installation. Scheduling regular inspections after installation helps you catch issues early and keep the system clean.

Maintenance Protocols for Longevity

You need to establish maintenance protocols that protect your smart power distribution unit and extend its lifespan. Regular inspections play a vital role in high-humidity environments. You should inspect and clean the power distribution unit at least quarterly. This practice prevents dust buildup and ensures proper ventilation. Clean cable management reduces service time and keeps the cabinet organized.

Here is a checklist for maintenance:

Clean all cable management trays and ties during each inspection.

Test and calibrate temperature and humidity sensors every six months.

Use remote monitoring to receive real-time alerts for preventive maintenance.

Clean the cabinet interior and exterior to remove dust and moisture.

Check for signs of corrosion or wear on connectors and outlets.

Verify that all cable management systems remain clean and functional.

Review historical monitoring data to identify trends and plan maintenance.

Ensure that all cable management paths are clean and unobstructed.

You maintain efficiency and protect your equipment by scheduling regular inspections and keeping cable management clean. Integrate monitoring tools into your cabinet management system for comprehensive environmental control. Clean installations and regular inspections help you deliver reliable power and efficient power distribution in challenging underground telecom environments.

Case Studies and Performance Outcomes

ESTEL Smart Power Distribution Unit Deployments

You see real-world results when you deploy ESTEL smart power distribution units in underground telecom cabinets. Many organizations have improved their infrastructure by using these advanced solutions. The following table shows how different companies benefit from smart power distribution unit installations:

Organization / Company | Impact / Result | Description |

|---|---|---|

IBM | Real-time monitoring of ESTEL PDUs in data centers reduced energy use. | |

U.S. General Services Administration | 41% energy savings, $13.5M annual cost savings | Smart PDUs improved efficiency and delivered financial benefits. |

New York City Underground Power Network | Enhanced reliability | Advanced PDUs prevented power failures in critical infrastructure. |

Vertiv (Fiji deployment) | Maintained IT and data center availability | ESTEL PDUs ensured telecom operations during outages. |

GUDE | Up to 30% reduction in energy waste | Measurement and monitoring capabilities supported sustainable energy use. |

You notice that each deployment of a smart power distribution unit leads to measurable improvements in energy savings and operational stability. These examples show how you can achieve better performance and reliability in underground telecom environments.

Safety and Reliability Improvements

You gain significant safety and reliability benefits when you choose moisture-proof smart power distribution units. Compared to traditional units, ESTEL solutions offer higher corrosion resistance, better moisture protection, and robust enclosures. The following table highlights the differences:

Feature | ESTEL Smart Power Distribution Units | Traditional Units |

|---|---|---|

Corrosion Resistance | High | Moderate |

Moisture Resistance | High | Low |

Temperature Tolerance | Extreme | Limited |

Component Protection | Robust enclosures | Standard |

Downtime Minimization | Modular design | Fixed components |

Equipment Failure Rate | Lower reported failures | Higher reported failures |

Operational Risks | Reduced | Increased |

You reduce downtime and prevent electrical failures by using smart power distribution units. Research shows a 25% increase in operational reliability and a 20% improvement in equipment uptime after installation. Real-time monitoring helps you detect issues early, preventing 80% of recent outages. You also respond to maintenance needs 40% faster, which keeps your network running smoothly.

Predictive maintenance leads to a 20% improvement in equipment uptime.

Real-time monitoring enhances operational efficiency by approximately 30%.

33% of downtime is attributed to power-related outages, which you can mitigate with intelligent power distribution units.

You see that smart power distribution units deliver strong performance and reliability in underground telecom cabinets. These solutions help you maintain safe, efficient, and resilient operations.

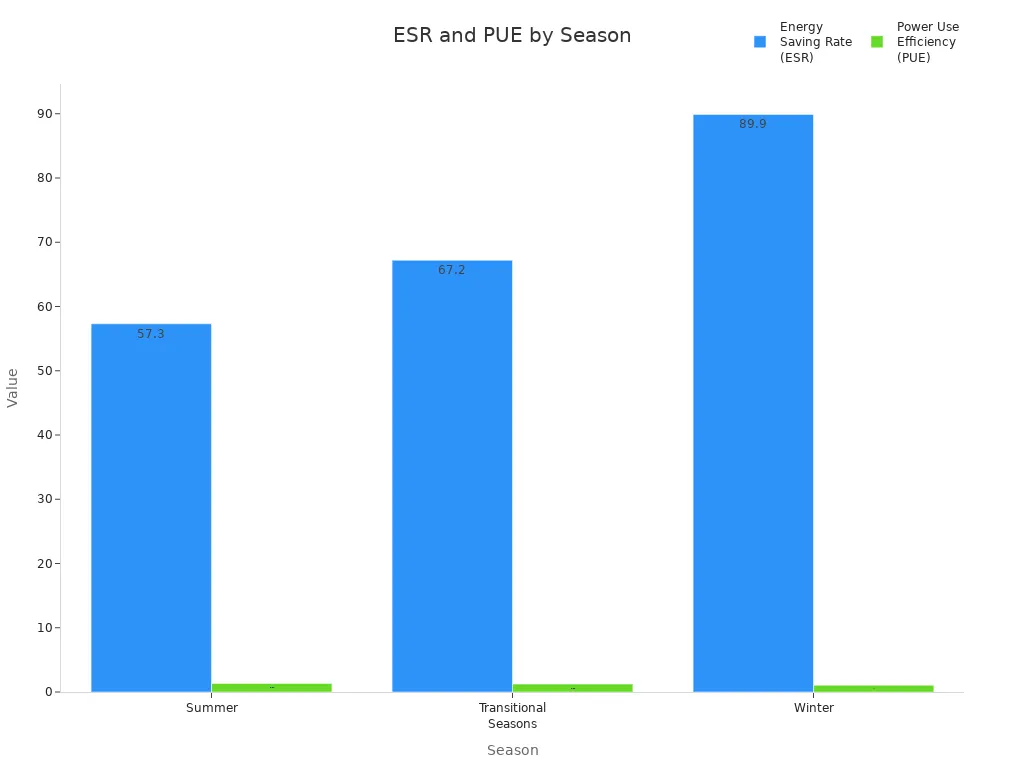

You improve electrical safety in underground telecom cabinets by using moisture-proof smart power distribution units. You protect your equipment from corrosion and breakdown when you manage temperature and humidity. The table below shows how energy savings and efficiency change with proper moisture control:

Metric | Summer | Transitional Seasons | Winter |

|---|---|---|---|

Energy Saving Rate (ESR) | 57.3% | 67.2% | 89.9% |

Power Use Efficiency (PUE) | 1.34 | 1.23 | 1.05 |

Annual ESR | 68.5% | N/A | N/A |

Annual PUE | 1.21 | N/A | N/A |

Payback Period (years) | 1.15 | N/A | N/A |

You should select smart power distribution units that offer strong safety features and reliable performance. ESTEL solutions provide hot-swappable modules, wide input voltage range, and advanced battery management. The table below highlights these advantages:

Feature | Advantage |

|---|---|

Perfect battery management | Prolongs battery lifetime through charge/discharge management, temperature compensation, and low-voltage protection |

Hot-swappable | Allows for easy replacement without downtime |

Input/Output protection | Ensures safety with over/under voltage and short-circuit protection |

Wide input voltage range | Adaptable to various power grids (85-300Vac) |

Front operation and cable access | Facilitates safe maintenance and good aesthetics |

Communication ports | Enables flexible networking and remote monitoring with RS485, internet port, etc. |

Hot pluggable rectifier and controller | Simplifies online maintenance |

Wide operating temperature range | Operates effectively in -5℃ to +55℃ |

Active power factor compensation | Achieves power factor >0.99 |

Dual outputs | Provides both -48Vdc and 220Vac options |

Dual inputs | Supports both -48Vdc and 220Vac inputs |

You reduce risks and improve safety when you choose advanced, moisture-proof technologies. You should continue to evaluate your systems and adopt new solutions to maintain reliable telecom operations.

FAQ

What makes a smart power distribution unit moisture-proof?

You get moisture-proof protection from rugged metal bodies, advanced sealing, and hydrophobic coatings. ESTEL’s units use these features to block water and prevent corrosion.

Tip: Always check for IP ratings to confirm moisture resistance.

How does the dehumidifying function work in ESTEL’s smart PDU?

You benefit from an integrated dehumidifier that actively removes moisture. It keeps humidity low inside your cabinet, protecting sensitive electronics and reducing the risk of condensation.

Can you monitor humidity levels remotely?

Yes, you can. ESTEL’s smart PDU supports remote monitoring through RS485 and app notifications. You receive real-time alerts for humidity changes, pump failures, and filter checks.

Feature | Benefit |

|---|---|

Remote alerts | Quick response |

Data logging | Maintenance planning |

How often should you inspect and maintain your smart PDU?

You should inspect and clean your smart PDU every three months. Test sensors and review monitoring data twice a year. Regular maintenance helps you prevent failures and extend equipment life.

What safety standards do ESTEL smart PDUs meet?

You get compliance with ISO9001, UL, CE, and RoHS standards. These certifications ensure your equipment operates safely in high-humidity environments and meets international requirements.

See Also

New Developments Shaping Outdoor Telecom Cabinet Designs

Strategies for Safeguarding Equipment in Outdoor Telecom Cabinets

Essential Features for Longevity of Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA