Solar Modules in High-Altitude Telecom Cabinets: Power Attenuation & Core Roles in Low-Pressure Environments

High-altitude telecom cabinets expose solar module systems to unique conditions. Increased solar irradiance at these elevations can enhance energy output, yet environmental stresses such as ultraviolet radiation, thermal cycling, and low pressure accelerate power attenuation. The table below summarizes how specific factors degrade performance:

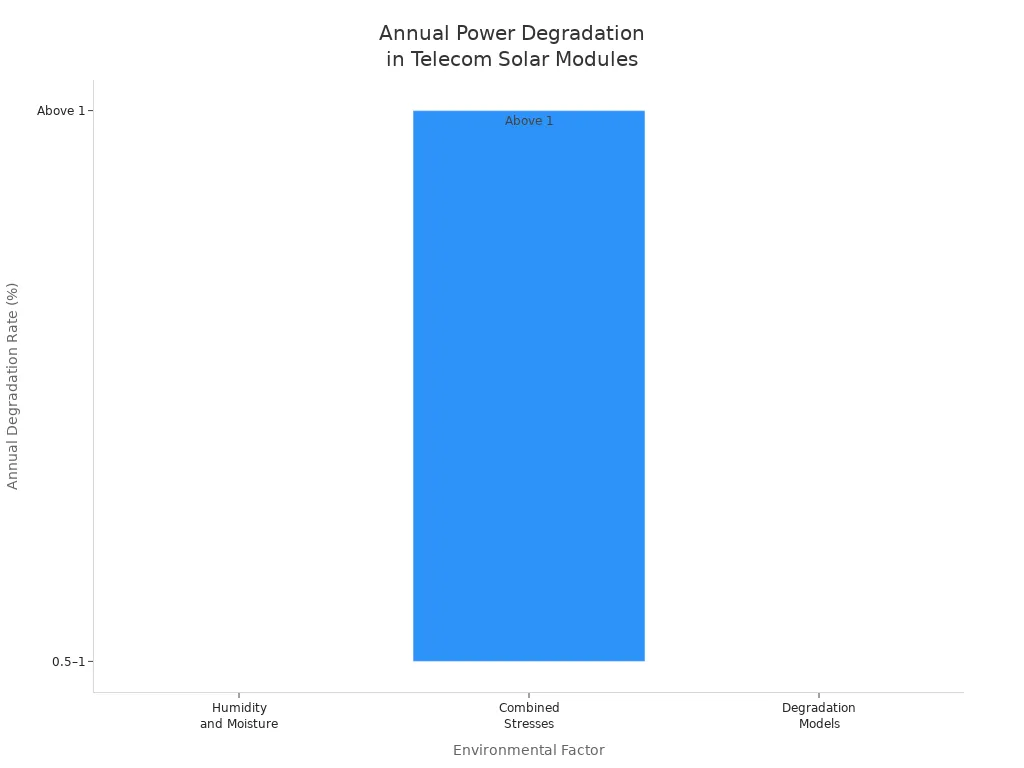

Environmental Factor | Degradation Mechanism(s) | Quantitative Effect on Power Attenuation |

|---|---|---|

Increased UV Radiation | Photodegradation, oxidation, corrosion | Reduced current; persistent power loss |

Thermal Cycling | Microcracks, solder fatigue | Efficiency loss; accelerated degradation |

Humidity and Moisture | Corrosion, delamination | Increased resistance; 0.5%-1% annual loss |

Combined Stresses | Synergistic effects | Linear or exponential power decay |

Telecom professionals must understand these challenges to ensure reliable, efficient power delivery in demanding environments.

Key Takeaways

High-altitude solar modules face power loss mainly from UV radiation and temperature swings, which speed up material wear and reduce efficiency.

Increased sunlight at high elevations boosts energy output but also raises risks like thermal stress and shading, which can cut power by up to 42%.

Choosing solar modules with strong UV resistance, low temperature sensitivity, and proper voltage ratings helps maintain performance and warranty coverage.

Regular cleaning and proactive maintenance, including dust removal and monitoring, prevent efficiency drops and extend module lifespan.

Using hybrid solar-diesel systems and smart energy management lowers fuel use, cuts costs, and improves network reliability in harsh environments.

Power Attenuation

Altitude Impact

High-altitude environments present unique challenges for telecom power systems. At higher elevations, solar irradiance increases due to thinner atmosphere and reduced scattering. This boost in sunlight can enhance energy production, but it also brings greater exposure to ultraviolet radiation and temperature swings. These factors accelerate degradation in solar modules, especially when combined with environmental stresses like wind and dust.

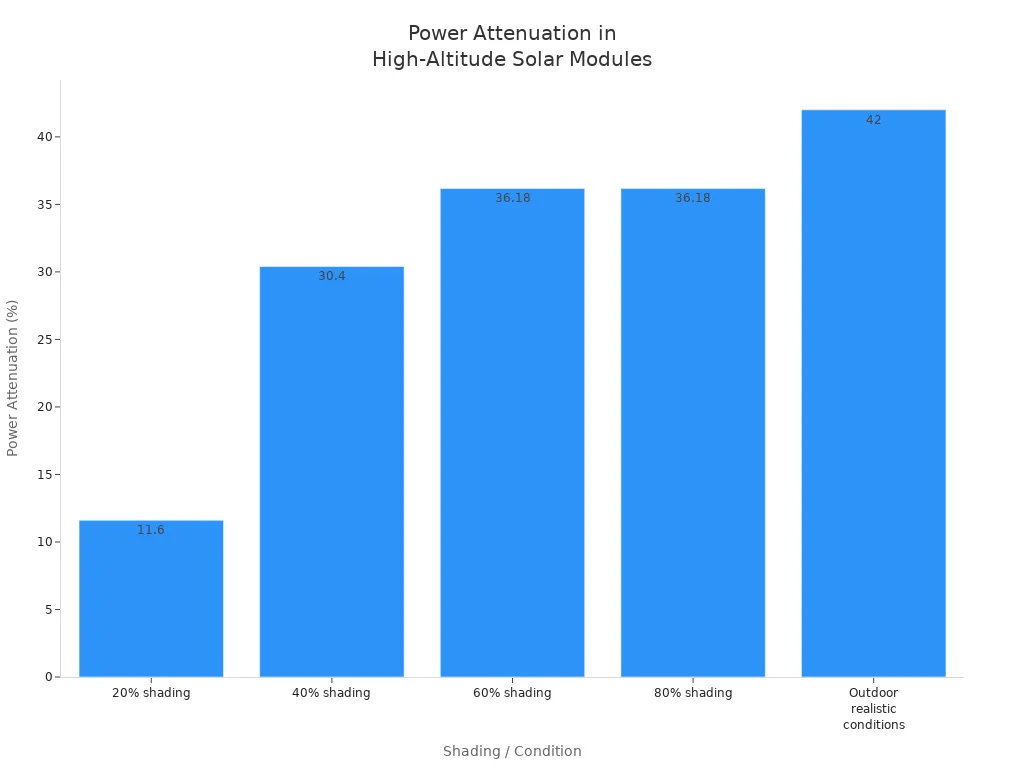

Shading remains a significant concern in these settings. Even partial shading can cause substantial power attenuation, leading to reduced energy output and the risk of hotspots. The table below summarizes typical power losses observed in high-altitude telecom deployments:

Shading Percentage | Power Attenuation (%) |

|---|---|

20% | |

40% | 30.4% |

60% | ~36.18% |

80% | ~36.18% |

Outdoor realistic conditions | Up to 42% |

Power attenuation at these levels can disrupt telecom operations and increase maintenance needs. Operators must consider shading patterns, module placement, and regular cleaning to minimize these losses.

Low Pressure Effects

Low atmospheric pressure at high altitudes affects both the physical and electrical performance of solar modules. Reduced air density leads to less convective cooling, causing module temperatures to rise more quickly under sunlight. Higher operating temperatures accelerate material fatigue and can reduce efficiency.

Economic impacts follow these technical challenges. As module temperatures climb, efficiency drops by about 0.5% for every degree Celsius above 25°C. For example, at 56°C, efficiency can decrease by over 3%. In extreme cases, such as 64°C, losses may reach up to 69%. These reductions in output increase operational costs and lengthen payback periods for telecom operators. However, colder ambient temperatures at high altitude can partially offset these losses by improving voltage output and efficiency.

Operators can mitigate these effects by selecting modules with low temperature coefficients and implementing cooling or ventilation strategies. Hybrid solar-diesel systems also help reduce generator runtime, fuel consumption, and maintenance costs, supporting both economic and environmental goals.

Temperature and UV Stress

Temperature swings and ultraviolet exposure represent the most significant degradation mechanisms for solar modules in high-altitude telecom cabinets. The table below outlines how different environmental factors contribute to module degradation:

Degradation Mechanism | Dependency Factors | Description and Quantitative Model Highlights |

|---|---|---|

Hydrolysis Degradation (k_H) | Effective relative humidity, temperature | Smallest contribution in most zones; higher in tropical climates with high humidity and temperature; causes moisture ingress and polymer delamination. Modeled as exponential function of temperature and humidity. |

Photo-Degradation (k_P) | Temperature, humidity, UV irradiation | Second highest contribution; triggered by UV dose combined with temperature and humidity; higher in tropical zones; lower in deserts due to low humidity despite high UV. Modeled with UV dose power law and exponential temperature dependence. |

Thermo-Mechanical Degradation (k_Tm) | Temperature swings (ΔT), cycling rate, upper module temperature | Highest contribution in most zones except tropical with minimal temperature variation; depends on seasonal temperature cycling and average max temperature; modeled with temperature difference raised to a power and exponential temperature term. |

Total Degradation Rate (k_T) | Combination of above three mechanisms | Expressed as % per year degradation rate; varies by climate zone; desert and steppe zones with very high irradiation show significant thermo-mechanical degradation; temperate zones average ~0.5%/a; cold/polar zones ~0.2%/a. |

Desert and steppe climates, which often overlap with high-altitude regions, experience high temperature swings and intense UV irradiation. These conditions drive up thermo-mechanical degradation rates. In temperate zones, average annual degradation rates reach about 0.5%, while cold or polar zones see rates closer to 0.2% per year. The combination of UV and temperature cycling in high-altitude environments makes robust module selection and regular maintenance essential for long-term reliability.

Power attenuation in solar modules affects energy output, which directly influences operational costs and payback periods.

High temperatures reduce solar module efficiency, causing output drops that can increase operational expenses.

In high-altitude (colder) environments, efficiency can improve due to lower temperatures, partially offsetting power attenuation.

Selecting solar modules with low temperature coefficients and implementing proper maintenance and cooling strategies mitigates power losses.

Economic benefits include up to 47% savings on annual operational expenditures and around 40% reduction in overall operating costs.

Hybrid solar-diesel systems reduce diesel generator runtime by up to 80%, cutting fuel consumption by up to 68%, lowering fuel and maintenance costs.

Solar-powered telecom cabinets reduce downtime by approximately 25%, improving network reliability and reducing indirect economic losses.

Reduced diesel use also lowers environmental compliance costs and supports sustainability goals, which have long-term financial advantages.

Payback periods for solar investments typically range from 3 to 6 years, after which cost savings improve profitability.

Smart energy management and advanced solar technologies further enhance economic outcomes by optimizing energy use and extending equipment life.

Solar Module Performance

Increased Irradiance

High-altitude locations receive stronger sunlight due to thinner atmosphere and reduced scattering. This increased solar irradiance directly boosts the energy output of solar modules. For every 1,000 meters gained in elevation, the atmospheric path shortens, allowing more solar energy to reach the panels. According to Beer-Lambert’s law, less solar radiation is absorbed or scattered at higher elevations. As a result, solar modules at these sites often generate more electricity than those at sea level. Cooler temperatures at altitude further improve photovoltaic efficiency, since solar panels operate better in lower heat. For example, temperature drops by about 6.5°C per kilometer of elevation, which helps maintain higher voltage and output.

However, this benefit comes with challenges. Increased irradiance also means higher exposure to ultraviolet (UV) radiation and more extreme temperature swings. UV rays accelerate the aging of encapsulant materials, such as EVA, causing yellowing and loss of transparency. Over time, this leads to higher series resistance and a drop in electrical performance. Field studies show that after 20 years of UV exposure, solar modules can lose up to 1.49% of their power output annually. Backsheet materials also degrade, losing strength and reflectivity, which further reduces module efficiency. These effects highlight the need for careful material selection and regular monitoring in high-altitude installations.

Note: Advanced AI-based models, such as GVSAO-CNN, have improved the prediction accuracy of solar irradiance and photovoltaic efficiency at high altitudes by over 22%. This allows for better system optimization and forecasting, helping operators maximize the benefits of increased irradiance while managing risks.

Soiling and Dust

Dust and particulate accumulation on solar modules can significantly reduce their efficiency. In high-altitude outdoor settings, the impact of soiling varies by region and environmental conditions. Studies in different climates have shown that heavy dust deposition can cause short-circuit current losses of up to 38.14%. In Pakistan, power output dropped by 11.54% to 16.16% after just one month of outdoor exposure. In the Saharan environment, an 8-week period led to a 6.1% decrease in current, while the UAE desert saw up to 30% reduction in light transmittance due to dust.

A case study in Kathmandu, a high-altitude city, found that dust accumulation caused power output losses ranging from 6% to over 30%, depending on dust density and local conditions. The study also noted that low rainfall and high air pollution can worsen soiling effects. Another experiment in Tehran measured a 21.47% reduction in power output after 70 days, with dust density reaching 6.1 g/m². In the UAE, each additional gram of dust per square meter led to a 1.7% drop in power.

Interestingly, atmospheric dust concentration generally decreases with altitude, except during dust storms. This means solar modules at higher elevations may experience less soiling-related performance loss compared to those at lower elevations. However, practical challenges such as maintenance access and structural support can limit the placement of solar panels at extreme heights.

Reliability Concerns

Solar modules in high-altitude environments face several reliability challenges. Environmental stresses, such as intense UV radiation, rapid temperature changes, and strong winds, accelerate material degradation. Modules often develop microcracks and delamination due to thermal cycling. Snow loads and wind can cause mechanical stress, while moisture ingress leads to corrosion of internal components.

Operators must address these risks to maintain system reliability. Robust monitoring systems help detect early signs of degradation, such as drops in output or visible damage. Preventive and predictive maintenance strategies, including regular inspections and cleaning, reduce downtime and extend module lifespan. The Vulnerability Stress Adaptation (VSA) model provides a framework for identifying and managing environmental stressors, enabling targeted adaptations that improve resilience.

Tip: Proactive maintenance and adaptive operational protocols are essential for reducing failure rates and ensuring long-term performance of solar modules in high-altitude telecom cabinets.

System Design

Energy Transfer

Efficient energy transfer forms the backbone of high-altitude telecom cabinet performance. Engineers design systems to maximize the capture, storage, and delivery of solar energy under challenging conditions. The following table outlines the main stages and strategies for optimizing energy transfer:

Energy Management Stage | Description | Role in Energy Transfer Optimization |

|---|---|---|

Stage 1: Energy Harvesting | Solar panels convert sunlight to electricity; MPPT divides energy between immediate use and battery charging. | Maximizes energy extraction and efficient distribution to systems and storage. |

Energy Storage | Surplus energy stored in lithium–sulfur batteries and gravitational potential energy (by climbing). | Provides energy reserve for non-solar periods, enhancing endurance. |

Stage 2: Energy Release | Gravitational potential energy released via gliding to power the aircraft when solar input is unavailable. | Extends operational time by utilizing stored energy efficiently. |

Stage 3: Sustained Flight Power | Lithium–sulfur battery supplies power for level flight during low solar input periods. | Maintains continuous operation, ensuring telecom payload functionality. |

System designers also focus on transmittance optimization. By adjusting the encapsulant’s transmittance, they balance solar radiation input and cell temperature. This approach prevents excessive heat buildup, which can degrade efficiency. Thermal and heat transfer modeling helps predict temperature variations, allowing for better control and material selection. Environmental factors such as latitude, date, and wind velocity influence these decisions, ensuring the system adapts to local conditions.

Battery Banks

Battery banks serve as the energy reservoir for telecom cabinets. Lithium–sulfur batteries have become popular due to their high energy density and long cycle life. These batteries store surplus energy during peak sunlight hours and release it during periods of low irradiance or at night. Engineers size battery banks based on expected load, solar input variability, and required backup duration. Proper management of charge and discharge cycles extends battery lifespan and maintains reliable power delivery. Advanced battery management systems monitor temperature, voltage, and state of charge, reducing the risk of failure and optimizing performance.

Enclosure Adaptations

Telecom cabinets at high altitude face harsh environmental stresses. Engineers implement several adaptations to protect sensitive electronics:

Reinforced mounting systems withstand increased wind loads and thermal expansion.

Corrosion-resistant materials and UV/moisture protective coatings extend equipment life.

Active cooling, wider air gaps, and optimized airflow compensate for reduced air density and natural convection.

Pressure equalization vents, such as GORE® Protective Vents, prevent seal stress and moisture ingress by equalizing internal and external pressure. These vents block liquids and particulates, allow water vapor to escape, and dissipate hazardous gases like hydrogen from batteries.

Regular monitoring with thermal imaging and temperature sensors ensures early detection of overheating or condensation.

Tip: Proper enclosure adaptation not only protects equipment but also reduces maintenance costs and downtime, supporting long-term reliability in high-altitude telecom operations.

Solar Module Selection

Rating Adjustments

Selecting solar modules for high-altitude, low-pressure environments requires careful adjustment of technical ratings. Engineers decrease module voltage ratings by 1.5% for every 1,000 meters of elevation. This adjustment helps prevent system overcharging and compensates for reduced atmospheric pressure. Modules with enhanced UV resistance and reinforced glass withstand increased ultraviolet exposure and mechanical stress. Preference goes to modules with temperature coefficients of -0.35%/°C or better, maintaining efficiency during rapid temperature changes. Manufacturers specify maximum elevation restrictions, so operators must review these limits to ensure compliance and warranty coverage. System designers also adjust spacing and mounting to optimize heat dissipation, considering reduced air density at altitude.

Rating Adjustment Aspect | Recommended Adjustment / Consideration | Purpose / Reasoning |

|---|---|---|

Voltage rating adjustment | Decrease module voltage ratings by 1.5% per 1,000 meters elevation | To compensate for reduced atmospheric pressure and prevent system overcharging |

Module material selection | Use modules with enhanced UV resistance and reinforced glass | To withstand increased UV exposure and mechanical stresses at high altitude |

Temperature coefficient | Prefer modules with temperature coefficients of -0.35%/°C or better | To maintain efficiency despite rapid temperature fluctuations common at high altitudes |

Manufacturer altitude ratings | Review maximum elevation restrictions specified by manufacturers | To ensure compliance with module design limits and warranty conditions |

System design considerations | Adjust spacing and mounting to account for reduced air density affecting heat dissipation | To optimize thermal management and maintain module performance |

Material and Structure

Material selection and structural design play a critical role in solar module durability at high altitude. Engineers often choose encapsulants such as EVA with higher vinyl acetate content for improved UV stability. Thermoplastic polyolefin (TPO) and composite encapsulants like EPE offer superior resistance to UV and thermal stress. For backsheets, options include PET for cost-effectiveness, PAPF for moisture resistance, and glass-glass structures for near-zero moisture permeability. Fully tempered glass (3.2 mm) provides high impact resistance and thermal stability, while semi-tempered glass improves optical performance in bifacial modules. Advanced materials, such as nanoscale carbon fillers and graphene, enhance UV stability and durability. UV-resistant multilayer backsheets or glass-glass designs are recommended for N-type cells, ensuring long-term performance under extreme conditions.

Tip: Regular maintenance and proper installation, including optimal module tilt, help reduce degradation rates and extend module lifespan.

Standards Compliance

International standards guide the selection and rating of solar modules for high-altitude applications. IEC 61853 defines a high-elevation climate profile for sites above 3,000 meters. The standard uses Climate-Specific Energy Rating (CSER) to calculate annual energy output under specific climate conditions. CSER compares module output in real-world climates to Standard Test Conditions, factoring in irradiance, temperature, wind speed, and spectral response. Satellite-based climate data and power matrices allow accurate prediction of module performance in high-altitude environments. This approach ensures consistent energy yield estimates and supports reliable system design.

IEC 61853 includes a dedicated high-elevation climate profile.

CSER methodology accounts for environmental factors such as irradiance, ambient temperature, wind speed, and module temperature.

Performance interpolation from the power matrix enables accurate output prediction in high-altitude conditions.

Maintenance Strategies

Monitoring

Effective monitoring forms the backbone of reliable telecom power systems in high-altitude environments. Operators deploy advanced technologies to track performance and detect issues early. Remote Terminal Units (RTUs) with Modbus compatibility and robust construction withstand extreme temperatures and weather. These units often feature TLS 1.2 encryption and strong authentication for secure data transmission. Wireless sensor networks using ZigBee technology provide low power consumption and strong signal penetration, even in challenging terrain. Operators integrate these sensors with Network Management Systems (NMS) or cloud platforms, enabling real-time alerts and centralized dashboards.

Aspect | Cellular Connectivity | Satellite Connectivity |

|---|---|---|

Coverage | Limited in remote areas | Global, including remote sites |

Data Transmission | Via cell towers | Via satellites |

Reliability | High, fallback to 4G/5G | Moderate, weather-dependent |

Cost | Lower | Higher |

Latency | Low | Higher |

Redundancy | Dual-mode devices supported | Dual-mode devices supported |

Operators often combine cellular and satellite connectivity to ensure continuous data flow. Morningstar charge controllers, with Maximum Power Point Tracking (MPPT), maximize energy extraction and support industrial protocols like MODBUS, MQTT, and SNMP. These controllers offer remote access, data logging, and built-in diagnostics, making them ideal for unattended, high-altitude telecom sites.

Cleaning

Dust and debris can quickly reduce energy output in high-altitude, dusty regions. Operators determine cleaning schedules based on local soiling rates and economic analysis. The following table summarizes optimal cleaning frequencies and costs for several locations:

Location | Cleaning Cost (US$/kWp) | Recommended Cleaning Frequency | Notes |

|---|---|---|---|

Iquique | 5 | Every 3 months | Balances soiling loss and cleaning cost |

Arica | 7 | Every 2 months | Higher soiling rates justify more frequent cleaning |

Calama | 7 | Every 6 months | Lower soiling rates allow longer intervals |

Operators adjust cleaning intervals seasonally, as soiling rates fluctuate throughout the year. In regions with occasional rainfall, natural cleaning may reduce the need for manual intervention. Cleaning becomes cost-effective when soiling losses match the expense of cleaning.

Preventive Measures

Proactive measures help mitigate environmental stressors and extend equipment lifespan. Operators address wind, snow, hail, and dust through targeted strategies:

Environmental Stressor | Impact on Modules | Recommended Preventive Measures |

|---|---|---|

Wind | Lowers module temperature, aids cooling | Harness wind-induced cooling for efficiency |

Snowfall | Can reduce output by up to 90% | Design for snow shedding or implement active snow removal |

Hailstorms | Causes 10–30% efficiency loss | Use robust materials or protective shielding |

Sandstorms | Drops efficiency by 20% within minutes | Schedule regular cleaning and dust mitigation |

Dust Accumulation | Increases maintenance costs, reduces output | Employ AI-driven predictive maintenance and scheduled cleaning |

Tip: Combining scheduled cleaning, robust monitoring, and environmental adaptations ensures long-term reliability and optimal performance in high-altitude telecom operations.

Solar module performance in high-altitude telecom cabinets depends on environmental stresses, material durability, and system design. Operators must select robust modules, adapt enclosures, and schedule regular maintenance. To maximize efficiency and reliability, experts recommend the following:

Dynamically switch transceiver states based on traffic demand to reduce power usage.

Deactivate unnecessary network resources during low demand periods.

Use lithium-ion batteries for energy storage and anticipate future improvements.

Deploy the maximum possible solar collector area within platform constraints.

Integrate hardware and software to boost system efficiency.

Ongoing adaptation remains essential as technology and environmental conditions change.

FAQ

What is the main cause of power loss in high-altitude solar modules?

UV radiation and temperature swings drive most power loss. These factors accelerate material degradation, leading to reduced efficiency and shorter module lifespan.

How often should operators clean solar panels in dusty, high-altitude areas?

Operators should assess local soiling rates. In many cases, cleaning every 2–3 months maintains optimal performance. Rainfall and dust storms may require more frequent cleaning.

Which solar module materials perform best at high altitudes?

Material Type | Key Benefit |

|---|---|

Tempered Glass | High impact resistance |

UV-Resistant EVA | Superior UV stability |

Glass-Glass Backsheet | Moisture protection |

Engineers prefer these materials for durability and reliability.

Can standard solar modules operate above 3,000 meters elevation?

Most standard modules have altitude limits. Operators should check manufacturer specifications and select modules rated for high-elevation use to ensure warranty coverage and long-term performance.

What maintenance strategies improve reliability in harsh environments?

Use remote monitoring for early fault detection.

Schedule preventive cleaning and inspections.

Apply protective coatings to resist UV and moisture.

These steps help extend equipment life and reduce downtime.

See Also

Solar Powered Energy Storage Solutions For Telecom Cabinets

Exploring The Function Of Outdoor Telecom Communication Cabinets

Latest Developments Shaping Outdoor Telecom Cabinet Technology

Essential Material Specifications For Outdoor Telecom Cabinets

Best Practices To Achieve Effective Monitoring Of Outdoor Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA