Solar Module Power Matching for Telecom Cabinets in High/Low Temp Environments: Key Differences Between 50W & 150W

Choosing the right solar module for telecom cabinets relies on understanding how temperature affects performance. Recent studies show that higher module temperatures decrease voltage output and efficiency, while cooler periods improve efficiency but may reduce power output. The temperature coefficient plays a critical role:

Panels with lower temperature coefficients maintain better energy output in extreme conditions.

Stable power reduces downtime and maintenance for telecom sites.

Improved durability lowers operational costs.

For harsh environments, 150W modules often provide more reliable power, but 50W modules suit smaller loads in milder climates.

Key Takeaways

High temperatures reduce solar module voltage and efficiency, so choosing panels with low temperature coefficients helps maintain stable power in hot climates.

50W modules work well for small, stable telecom loads in mild climates, while 150W modules provide better reliability and power for larger or hot environment sites.

Cold weather improves solar module efficiency by increasing voltage, but operators should watch for snow or dust buildup that can block sunlight.

Regular maintenance using thermal imaging and temperature sensors helps detect early faults, preventing costly failures and extending module life.

Matching solar module size and type to site power needs and climate conditions reduces downtime and supports long-term telecom cabinet performance.

1. Solar Module Temperature Impact

High Temperature Effects

Voltage and Efficiency Drop

High temperatures cause a noticeable reduction in the voltage output of a solar module. As the temperature rises, the current increases only slightly, but the voltage drops significantly. This leads to a decrease in overall efficiency. For every 1°C increase in cell temperature, electrical efficiency drops by about 0.03–0.05%. At 56°C, efficiency can fall by 3.13%, and at 64°C, the drop can reach a dramatic 69%.Effect/Parameter

Observation/Value

Voltage change with temperature

Voltage reduces significantly as temperature increases, while current increases slightly

Efficiency temperature coefficient

Approximately -0.5% per °C

Efficiency decrease per °C increase

0.03–0.05% decrease in electrical efficiency per 1 °C rise in cell temperature

Efficiency drop at 56 °C

3.13% decrease

Efficiency drop at 64 °C

69% decrease

Power degradation rate in field-aged modules

About 0.8% per year, linked to degradation in temperature coefficients of voltage parameters

Optical degradation effects

Causes hotspots and reduces photon absorption, increasing cell temperature differences (~10 ± 2 °C)

Temperature coefficients reliability

Field measurements agree well with laboratory values; degradation observed in older modules

Cell Type Differences

N-type solar cells handle heat better than P-type cells. N-type cells have a lower temperature coefficient, which means they lose less efficiency as temperatures climb. This makes them more reliable for telecom cabinets in hot climates.Aspect

N-Type Solar Cells

P-Type Solar Cells

Temperature Coefficient

Lower (better heat tolerance)

Higher (more efficiency loss at high temps)

Heat Tolerance

Enhanced

Less heat tolerant

Performance in Harsh Conditions

More stable and reliable

Less stable

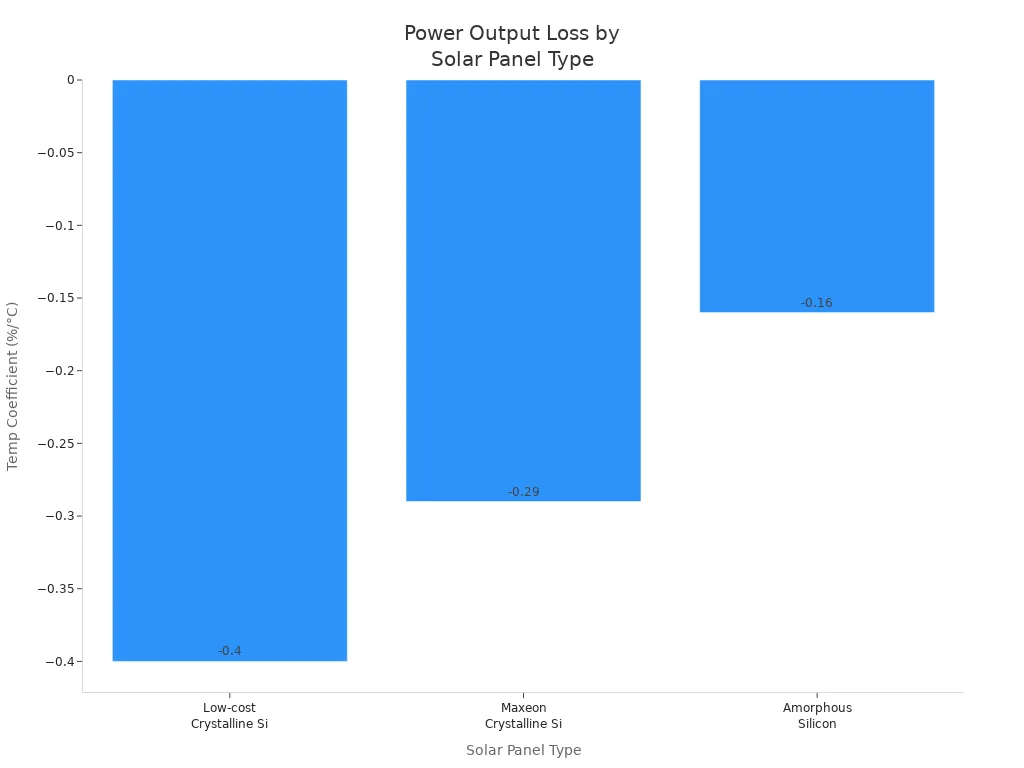

Module Technology Comparison

Thin-film modules, such as amorphous silicon, show better thermal stability than crystalline silicon modules. Thin-film modules have a lower temperature coefficient, so they maintain higher efficiency in hot environments.

Module Type

Temperature Coefficient (%/°C)

Efficiency Range (%)

Thermal Performance Summary

Crystalline Silicon

13 - 20

Higher temperature coefficient leads to greater efficiency loss at elevated temperatures. Performs best in cooler climates.

Thin-Film (CIGS)

~ -0.16

10 - 14.5

Lower temperature coefficient results in less efficiency loss at high temperatures; more thermally stable and better suited for hot climates.

Amorphous Silicon

~ -0.16

N/A

Similar low temperature coefficient, contributing to better performance under heat stress.

Tip: Selecting a solar module with a lower temperature coefficient ensures more stable power output in hot climates.

Low Temperature Effects

Efficiency Gains

Cooler temperatures improve the efficiency of a solar module. Lower cell temperatures reduce electrical resistance, which helps the module produce more power. Crystalline silicon modules perform best in these conditions, as their efficiency loss from heat is minimized.Environmental Interactions

In cold environments, factors like humidity and dust still affect performance. Dust can block sunlight and raise panel temperatures even in winter, while humidity can cause insulation failures. Wind can help cool the modules, but it may also increase dust accumulation. Regular cleaning and weatherproofing remain important for telecom cabinets.Reliability Over Time

Temperature swings, especially in outdoor telecom installations, can accelerate material aging. Choosing corrosion-resistant and weatherproof modules with good thermal insulation helps maintain long-term reliability.

2. Power Output Comparison

50W vs 150W in Heat

Performance Drop in High Temperatures

Both 50W and 150W modules lose efficiency as temperatures rise. The larger 150W module, however, often handles heat better due to improved design and higher-quality materials.Voltage and Current Behavior

In hot conditions, voltage drops for both module sizes. The current may increase slightly, but the overall power output decreases.Impact on Telecom Cabinets

Telecom cabinets with higher power needs benefit from the 150W module. It provides more headroom to offset losses from heat.Comparison Table

Module Size

Typical Power Loss at 45°C

Suitability for High Loads

Notes

50W

2–3W

Low

May struggle in extreme heat

150W

6–10W

High

Maintains better output

Note: A 150W solar module can better support critical telecom equipment during heat waves, reducing the risk of power shortages.

50W vs 150W in Cold

Efficiency Gains in Low Temperatures

Both modules see improved efficiency in cold weather. The voltage increases, which boosts total power output.Power Output Stability

The 50W module performs closer to its rated output in cold climates. The 150W module also benefits, often exceeding its nominal rating during sunny, cold days.Best Use Cases

Small telecom sites with low energy demand can use 50W modules effectively in cold regions. Larger sites or those with fluctuating loads should choose 150W modules for extra reliability.Comparison Table

Module Size

Output at 0°C (Clear Sky)

Ideal Application

Reliability in Cold

50W

50–54W

Small, stable loads

High

150W

150–162W

High or variable loads

Very High

Tip: Cold weather boosts solar module output, but snow and ice buildup can block sunlight. Regular maintenance ensures consistent performance.

3. Solar Module Efficiency

Efficiency Losses

Solar modules experience efficiency losses due to several environmental and design factors. The following list outlines the main causes:

Ambient air temperature raises the operating temperature of the panel.

Intense solar irradiance heats the module surface.

Wind speed cools panels, lowering temperature by 5–11°C at 1 m/s wind.

Installation method affects airflow; roof-mounted panels run hotter than ground-mounted ones.

Panel color and materials influence heat absorption; darker panels absorb more heat.

Higher efficiency panels tend to operate at cooler temperatures.

Time of day determines temperature peaks.

Geographical location, including latitude and altitude, impacts operating temperature.

High temperatures cause significant system losses in solar modules. Output drops by about 0.5% for every 1°C above 25°C. For example, at 45°C, a panel may lose 8% efficiency, and at 65°C, losses can reach 16%. Extreme conditions can push losses over 20%. The main reason for these losses is increased carrier concentration in the semiconductor, which leads to higher recombination rates and reduced voltage. Electrical resistance in cell contacts also rises, further decreasing efficiency.

Note: Cooling techniques such as natural ventilation, heat sinks, and phase change materials can help reduce thermal losses and improve module stability.

A table below summarizes how design choices affect efficiency:

Design Factor | Impact on Efficiency |

|---|---|

Polymer backsheets | Lower heat dissipation |

Glass-glass modules | Higher heat dissipation |

Front-side busbars | Hotspot risk |

Back-contact/fine-grid design | Improved thermal stability |

Efficiency Gains

Solar modules can achieve efficiency gains under certain conditions. Cold environments often boost performance because lower cell temperatures increase voltage output. In some cases, panels perform better than their rated efficiency during cold, sunny days.

Copper indium gallium selenide (CIGS) PV cells retain efficiency better than crystalline silicon cells when temperatures fluctuate.

Hybrid PV modules that use cool water from desalination systems can enhance performance in hot climates.

Glass-glass modules dissipate heat more effectively, reducing operating temperature by 2–3°C.

Tip: Selecting modules with advanced cooling features or better thermal design can help maintain high efficiency, especially in challenging climates.

4. Reliability and Longevity

Durability in Extreme Temperatures

Thermal Stress and Material Fatigue

High temperatures and rapid temperature swings create thermal stress in photovoltaic modules. This stress leads to material fatigue, cracking, and delamination. Solder joints may fail, and encapsulant materials can age faster. For example, when temperature differences exceed 15°C, thermal stresses above 10 MPa can develop, causing mechanical damage. UV radiation combined with heat accelerates yellowing and delamination of packaging materials, which reduces light transmission and efficiency.Mechanical Failures from Temperature Cycling

Daily expansion and contraction from temperature changes can loosen fixtures and damage internal components. In desert climates, modules may face temperatures from 20°C to over 90°C, increasing the risk of solder bond failures and busbar breakages. Encapsulant discoloration and backsheet cracks also become more common under these harsh conditions.Hotspots and Power Loss

As surface temperatures rise from 25°C to 45°C, hotspots can form. These localized areas of high temperature cause further degradation and power loss. Potential-induced degradation (PID) becomes more severe at higher temperatures and humidity, leading to faster reliability failures.

Note: Selecting modules with enhanced mechanical and thermal durability helps reduce the risk of early failure in telecom cabinets exposed to extreme environments.

Maintenance Needs

Routine Monitoring with Advanced Tools

Thermal imaging cameras provide a non-contact way to monitor system health. They detect temperature variations and identify faults early, preventing costly failures.

These cameras offer both a broad overview and detailed inspection, measuring temperature differences accurately.

The method is non-destructive and speeds up inspections compared to traditional approaches.

Diagnostic and Analytical Techniques

Infrared thermography helps detect overheating and material degradation without damaging the equipment.

Advanced tools like scanning electron microscopy and spectroscopic methods give deeper insights into failure mechanisms.

Low-Cost Monitoring Solutions

Temperature sensors such as DS18B20, combined with data loggers, track operating temperatures inside cabinets.

These systems can connect via 3G or Wi-Fi for remote monitoring, ensuring real-time oversight of electrical and environmental conditions.

Tip: Regular inspections using thermal imaging and temperature sensors help locate small issues before they escalate, saving time and money for telecom operators.

5. Module Selection for Telecom Cabinets

Choosing 50W Modules

Telecom sites with low power needs or stable, mild climates often benefit from 50W modules. These modules work well for small cabinets or backup systems. Operators should consider the following when selecting 50W modules:

Use in regions with moderate temperatures and minimal seasonal swings.

Install in areas with consistent sunlight and low risk of shading.

Choose for cabinets with limited space or where weight is a concern.

Inspect cabinets quarterly for dust, corrosion, and pests.

Remove snow buildup in cold climates to prevent stress on the panel.

Employ heaters or insulation for winter protection if needed.

Tip: 50W modules suit small, stable loads and require less space, making them ideal for remote or compact telecom sites.

Choosing 150W Modules

Larger telecom cabinets or those in harsh environments often require 150W modules. These modules provide extra power and reliability. Key considerations include:

Select for sites with high or variable power demands.

Use in hot climates where efficiency losses are greater.

Install corrosion-resistant mounting structures, especially in humid or coastal areas.

Apply anti-corrosion coatings annually to extend lifespan.

Integrate temperature control modules, such as cooling fans or air conditioning, in hot climates.

Secure mounting to withstand strong winds and storms.

Note: 150W modules offer more headroom for power losses and support critical equipment during extreme weather.

Power Matching Strategy

Choosing the right solar module size depends on both environmental conditions and load requirements. Operators should follow these steps:

Assess the total power demand of the telecom cabinet.

Evaluate local climate—hot climates need modules with low temperature coefficients.

Plan site layout to avoid shading and ensure good airflow.

Inspect steel support structures at least twice a year, focusing on corrosion in humid areas.

Customize enclosure ratings (IP65/NEMA 4/4X) to match environmental challenges.

Maintain firmware and battery health for reliable operation.

A table below summarizes the decision process:

Site Condition | Recommended Module | Key Actions |

|---|---|---|

Mild, stable climate | 50W | Basic maintenance, snow removal |

Hot/humid climate | 150W | Cooling, corrosion protection |

High/variable load | 150W | Enhanced monitoring, airflow |

Operators who match module size to site needs and climate can reduce downtime and extend equipment life.

50W modules suit mild climates and stable, low-power telecom loads, while 150W modules deliver better reliability in harsh or high-demand environments.

Temperature coefficients and module type selection directly affect efficiency and long-term performance. Panels with lower coefficients and robust construction withstand extreme conditions.

Field data highlights the importance of matching cabinet type, environment, and power management:

Cabinet Type | Key Protection Features | Power Module Advice |

|---|---|---|

Outdoor | Weatherproofing, advanced cooling | High-efficiency, hot-swappable, solar-ready |

Indoor | Robust steel, secure airflow | Compact, modular, redundant |

Shared/Modular | Expandable, adaptable systems | Scalable, renewable-compatible, advanced monitoring |

Telecom engineers should assess site conditions, plan for expansion, and prioritize regular maintenance to ensure stable, efficient operation over decades.

FAQ

1. How does temperature affect solar module performance?

High temperatures lower voltage and efficiency in solar modules. Cold temperatures increase voltage and can boost output. Modules with lower temperature coefficients lose less power in heat. Operators should always check the temperature rating before choosing a module.

2. Which module type works best in extreme climates?

N-type and thin-film modules perform better in hot environments. These modules have lower temperature coefficients. Crystalline silicon modules work well in cold climates. Operators should match module type to the local climate for best results.

3. Can a 50W module power a telecom cabinet in hot weather?

A 50W module may struggle in high temperatures. Power output drops as heat rises. For cabinets with higher loads or in hot regions, a 150W module offers more reliable performance and reduces the risk of power shortages.

4. How often should operators inspect solar modules?

Operators should inspect modules at least twice a year. In harsh climates, quarterly checks help catch dust, corrosion, or damage early. Regular cleaning and monitoring extend module life and keep telecom equipment running smoothly.

5. What maintenance tools help monitor solar modules?

Thermal imaging cameras and temperature sensors help detect faults early. These tools provide fast, non-contact checks. Operators can spot overheating, material fatigue, or electrical issues before they cause failures.

See Also

Exploring Various Cooling Techniques Used In Telecom Cabinets

Solar Energy Storage Solutions Designed For Telecom Cabinets

Tips To Maintain Ideal Temperatures In Outdoor Telecom Cabinets

Essential Material Specifications For Outdoor Telecom Cabinet Construction

Selecting The Most Effective Cooling Options For ESTEL Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA