Outdoor Telecom Cabinet Solar Module Selection: Dual Analysis of Power & Roles in UV Resistance/Waterproofing/Weather Durability

Selecting the right solar module for outdoor telecom cabinets poses a unique challenge. Engineers must ensure consistent power delivery and defend sensitive equipment against harsh elements. Common threats include intense UV radiation, water ingress, and temperature swings.

Common Environmental Challenges | Material/Design Considerations | |

|---|---|---|

Coastal Areas | High humidity, salt-laden air causing corrosion | Use stainless steel for corrosion resistance |

Desert Environments | Extreme heat, UV radiation | Use aluminum for heat dissipation and UV resistance |

Urban/Industrial Zones | Pollution, chemical exposure, physical stress | Use galvanized steel; composites for strength |

General Challenges | Moisture ingress, temperature fluctuations, vandalism | Waterproofing, ventilation, security features |

Long-term reliability depends on careful material selection and site-specific protection strategies. Each outdoor telecom cabinet requires a solar module that matches its environment and delivers stable performance year after year.

Key Takeaways

Calculate total power needs carefully by adding internal device loads and external heat factors, always including a safety margin to ensure reliable operation.

Size solar modules based on daily energy use, local sunlight hours, and add safety margins to handle bad weather and future growth.

Choose UV-resistant, waterproof, and weather-durable materials like polycarbonate and corrosion-resistant metals to protect solar modules from harsh outdoor conditions.

Install solar modules with proper tilt angles and secure mounts to maximize energy capture and withstand wind, hail, and other climate risks.

Perform regular maintenance, including cleaning and inspections, to keep solar modules efficient and extend their lifespan while reducing downtime.

Power Needs

Load Calculation

Accurate load calculation forms the foundation of reliable power design for outdoor telecom cabinets. Engineers begin by listing all equipment inside the cabinet, such as routers, switches, cooling fans, and monitoring devices. Each device's power consumption and operating hours are recorded. The total internal heat load (Q_i) is calculated by multiplying each device's power by its runtime and summing the results.

External heat load (Q_r) also plays a significant role. This value depends on the cabinet's material, surface area, temperature difference between inside and outside, and the solar heat gain coefficient. The formula for external heat load is:

Q_r = (U x A x ΔT) + (SHG x A)

Where:

U = heat transfer coefficient of the cabinet material

A = surface area

ΔT = temperature difference

SHG = solar heat gain coefficient

After determining both internal and external heat loads, engineers sum them to get the total heat load (Q_total). To ensure reliability, they apply a safety factor, typically multiplying by 1.2. This approach accounts for unexpected environmental changes and equipment upgrades. The final value guides the sizing of cooling systems and backup power.

Tip: Always include a safety margin in load calculations to prevent system overload and extend equipment lifespan.

Solar Module Sizing

Proper sizing of the solar module ensures uninterrupted operation of telecom cabinets, even in remote or challenging environments. The process starts with a detailed assessment of daily energy consumption. Engineers list all devices, calculate their total energy needs, and factor in the runtime for each.

Several factors influence the final solar module size:

Local weather conditions and sunlight hours, which vary by season and geography.

Safety margins, often set at twice the calculated requirement, to cover cloudy days or future expansion.

Battery capacity and desired charge time, which affect how quickly the system can recover from outages.

Selection of high-efficiency panels to maximize output in limited space.

A common sizing formula is:

PV Size = Margin × (Daily Consumption) / (Light Exposure Hours)

This formula ensures the solar module can meet energy demands, even during periods of low sunlight. Engineers also consider installation methods, ensuring stable mounting and minimal shading. Environmental durability, such as resistance to wind, corrosion, and temperature swings, remains a priority for long-term performance.

Sizing Factor | Consideration |

|---|---|

Daily Power Consumption | List all equipment and calculate total needs |

Sunlight Hours | Adjust for seasonal and geographic variation |

Safety Margin | Typically 2x for reliability |

Battery Capacity | Match to backup and charge requirements |

Panel Efficiency | Choose high-efficiency models for limited space |

Environmental Durability | Ensure resistance to weather and corrosion |

Efficiency Factors

Efficiency determines how well a solar module converts sunlight into usable power. Seasonal variations in sunlight directly impact efficiency and energy output. During winter or rainy seasons, reduced sunlight hours can lower the system's performance. Operators often compensate by increasing the size of the solar module or optimizing the angle and placement of photovoltaic panels.

Temperature extremes also affect battery performance and overall system reliability. Proper enclosure design, including thermal protection and ventilation, helps maintain efficiency throughout the year. Monitoring tools track power usage and system health, allowing for timely maintenance and adjustments.

Note: Consistent efficiency requires regular inspection and cleaning of solar modules, especially in dusty or polluted environments.

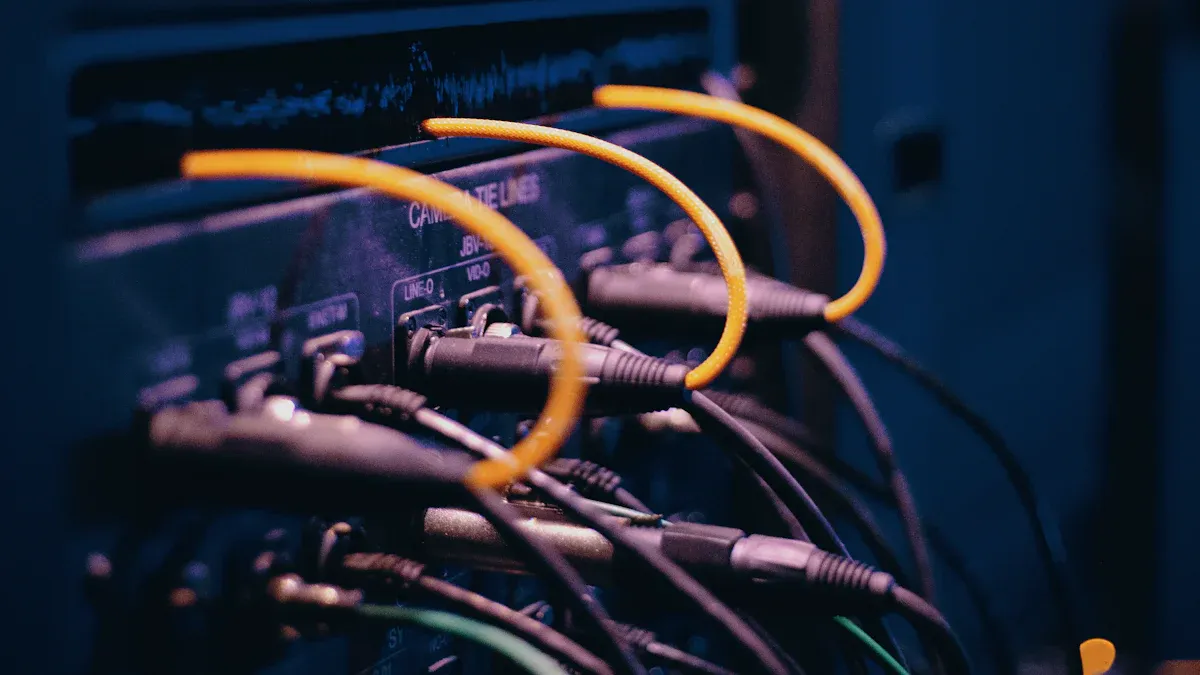

Outdoor telecom cabinets often rely on DC48V or AC220V power systems, with integrated UPS and battery backup to ensure continuous operation. Power distribution units, surge protection, and modular designs support scalability and future upgrades. High IP-rated enclosures shield sensitive electronics from dust and moisture, further supporting efficient and reliable operation.

Solar Module Environmental Protection

Outdoor telecom cabinets face constant exposure to sunlight, rain, dust, and temperature extremes. The solar module must withstand these challenges to ensure reliable power delivery and protect sensitive electronics. Three critical aspects—UV resistance, waterproofing, and weather durability—define the environmental protection of solar modules in these demanding settings.

UV Resistance

Prolonged exposure to ultraviolet (UV) radiation can degrade materials, causing discoloration, brittleness, and loss of mechanical strength. For outdoor telecom applications, UV resistance is essential to prevent premature aging and maintain system reliability. Manufacturers select materials such as cross-linked polyethylene (XLPE), polyvinyl chloride (PVC), and polycarbonate (PC) for their proven UV-resistant properties. These materials comply with industry standards like UL 4703, IEC 60332, and the National Electrical Code, which ensure safety, flame retardancy, and environmental durability.

Material | Key UV Resistance Features | Application in Outdoor Telecom Solar Modules |

|---|---|---|

Polycarbonate (PC) | High impact resistance, UV stabilizers, withstands -40°F to 250°F | Used for durable, UV-resistant enclosures and module components |

Fibreglass Reinforced Polyester (FRP) | Excellent UV stability, corrosion resistant, strong composite structure | Ideal for harsh outdoor environments requiring UV and chemical resistance |

UV-Stabilized ABS | UV-stabilized variants, good impact resistance, lightweight, cost-effective | Used where cost and weight are considerations but UV resistance is needed |

Engineers often use encapsulants like ethylene vinyl acetate (EVA) with titanium dioxide (TiO2) filler to improve UV stability, especially for bifacial cells. Thermoplastic polyolefin (TPO) offers superior UV resistance and thermal stability, reducing discoloration over time. Polymer backsheets with polyvinylidene fluoride (PVDF) outer layers provide additional UV protection and moisture resistance. Advanced multilayer films, such as those made from polycarbonate (PC) and polymethyl methacrylate (PMMA), reflect UV light while allowing visible light to pass, further enhancing the longevity of the solar module.

Tip: Selecting UV-stable materials for both the front cover and encapsulant layers helps prevent aging and ensures long-term performance in outdoor telecom environments.

Waterproofing

Waterproofing protects the solar module and cabinet electronics from moisture, condensation, and environmental contaminants. Robust enclosure designs that meet IP65 or IP66 standards offer resistance to dust and water jets, which is vital for outdoor installations. Manufacturers use corrosion-resistant materials and advanced sealing techniques, such as gaskets, O-rings, and silicone sealants, to create watertight barriers.

Well-designed enclosures feature minimal seams and may include drainage channels to prevent water accumulation. Rubber seals play a crucial role in maintaining the integrity of the enclosure, shielding sensitive components from water ingress. These measures undergo rigorous testing and certification to ensure they withstand harsh outdoor conditions.

Waterproofing not only extends the operational lifespan of the solar module but also ensures uninterrupted power supply for telecom equipment, even during heavy rain or high humidity.

Weather Durability

Weather durability encompasses the solar module’s ability to resist a wide range of environmental stresses, including temperature extremes, wind, rain, dust, and mechanical impacts. Engineers select corrosion-resistant metals such as aluminum and stainless steel for frames and mounting structures. These metals maintain structural integrity and electrical conductivity, even in coastal or high-humidity environments. Protective coatings and design features like drainage channels and watertight seals further enhance durability.

Testing methods for weather durability include:

Acceleration and corrosion testing

Fungus resistance and humidity exposure

Icing, freezing rain, and immersion tests

Ingress protection (IP) ratings such as IP65 and IP67

Salt-fog, sand, and dust testing

Solar radiation and temperature cycling

Thermal shock, vibration, and wind & rain simulation

Industry standards such as ASTM, IEC, ISO, UL 1703, UL 50, UL 50E, and MIL-STD-810 guide these tests. These protocols simulate real-world stresses to verify the enclosure and component integrity. Features like enclosure heaters prevent condensation, reducing equipment failures. Field data from telecom projects show that switching to these robust enclosures can reduce failures by up to 80%.

Using corrosion-resistant metals and rigorous testing protocols ensures the solar module delivers stable performance and long service life, even in the harshest outdoor environments.

Installation & Compatibility

Mounting

Engineers select mounting options based on site conditions and cabinet design. Common choices include side-of-pole mounts, top-of-pole mounts, roof-ground mounts, and skid mounts. These mounts attach to poles, ground, walls, or roofs, providing flexibility for different environments. Manufacturers use materials such as aluminum, anodized aluminum, painted steel, and galvanized steel to ensure durability and resistance to corrosion. Aircraft-grade structural members and stainless steel fasteners enhance stability, especially in high wind zones.

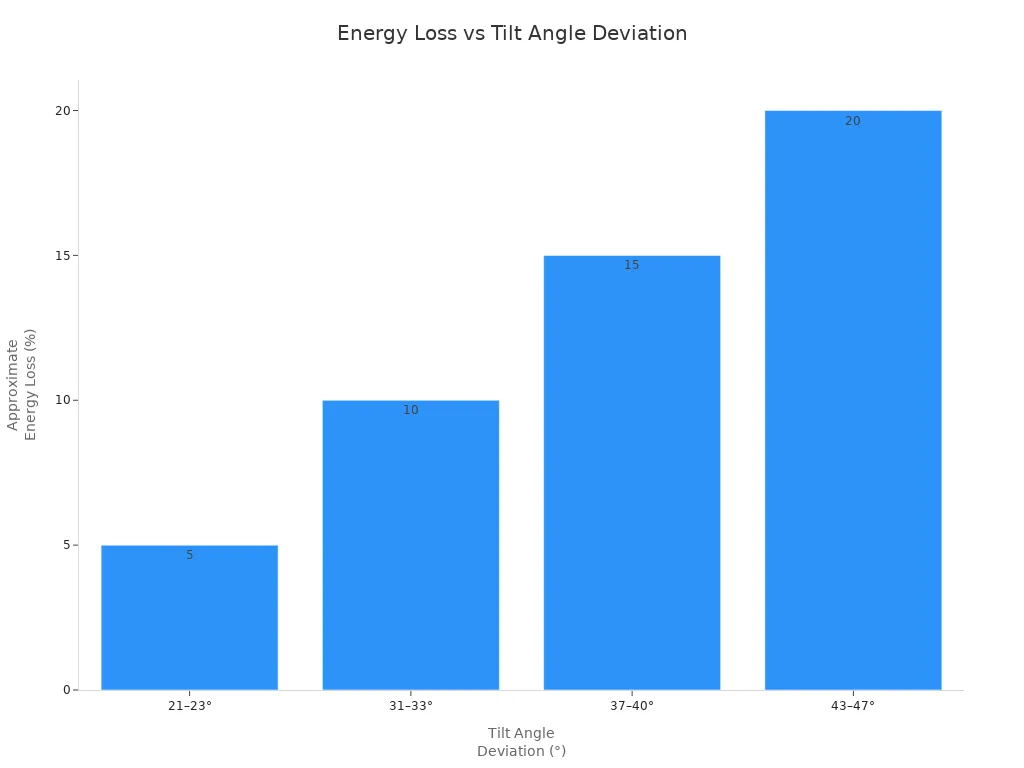

Adjustable tilt mounts allow seasonal optimization of solar exposure, while fixed position mounts offer simplicity but lack flexibility. Proper tilt angle alignment is critical for maximizing energy output. Even small deviations can cause significant energy loss, as shown below:

Tilt Angle Deviation (°) | Approximate Energy Loss (%) |

|---|---|

21–23 | Around 5% |

31–33 | Around 10% |

37–40 | Around 15% |

43–47 | Around 20% |

Professional installation teams adjust tilt angles based on geographic location and sunlight exposure, ensuring optimal performance and longevity.

Electrical Integration

Electrical integration requires careful planning to match the solar module with the telecom cabinet’s power system. Engineers verify compatibility with DC48V or AC220V systems and ensure proper grounding to protect against lightning strikes and surges. Secure electrical connections and surge protection devices maintain system safety. Integration teams use modular designs for scalability, supporting future upgrades without major rewiring. Monitoring tools track energy production and system health, enabling proactive maintenance and minimizing downtime.

Maintenance

Routine maintenance preserves the reliability and efficiency of solar modules in telecom applications. Teams inspect door seals and gaskets regularly, replacing damaged components to prevent moisture and dust ingress. They verify cabinet doors and locks to ensure security and environmental protection. Grounding systems receive periodic checks to maintain safety.

Recommended maintenance routines include:

Cleaning solar modules biannually or more often in dusty areas.

Inspecting panels quarterly for physical damage and corrosion.

Monitoring system performance monthly using dedicated tools.

Checking inverter indicators monthly for warnings.

Inspecting after severe weather events for damage or displacement.

Engaging licensed professionals every three years for thorough inspections.

Trimming vegetation annually to prevent shading.

Following strict safety protocols during maintenance.

Regular maintenance prevents minor issues from escalating, extends equipment lifespan, and ensures consistent power delivery. Remote monitoring tools support proactive scheduling, reducing costly repairs and maximizing system benefits.

Cost & Warranty

Long-Term Value

Solar modules for outdoor telecom cabinets represent a significant investment. Decision-makers must evaluate more than just the initial purchase price. They consider the entire lifecycle cost, which includes installation, maintenance, replacement, and residual value. Galvanized steel stands out as a preferred structural material. It offers a high strength-to-weight ratio and resists corrosion, supporting a lifespan of 20 to 25 years. This durability reduces the frequency of repairs and replacements, lowering total ownership costs.

Protective coatings such as hot-dip galvanizing further extend the life of steel components. Modular steel designs simplify installation and allow for easy upgrades, minimizing downtime. Real-world projects show that steel structures maintain high uptime and require less maintenance, even in harsh environments. Regular inspections and professional installation ensure the system operates reliably. Compliance with local building codes also protects the investment.

Site-specific factors play a crucial role in long-term value. Load capacity, local climate, soil type, and installation quality affect energy yield and structural integrity. Steel’s recyclability supports sustainability and offers potential cost recovery at the end of the module’s life.

Tip: Lifecycle cost assessments help organizations plan for future expenses and maximize return on investment.

Key contributors to long-term value:

Choice of corrosion-resistant materials

Protective coatings and modular designs

Lifecycle cost analysis

Sustainability and recyclability

Professional installation and regular maintenance

Compliance with building codes

Warranty Support

Warranty coverage provides assurance for telecom operators investing in solar modules. Leading manufacturers offer warranties ranging from 10 to 25 years, covering defects in materials and workmanship. Extended warranties may include performance guarantees, ensuring the module delivers a specified energy output over time.

Operators should review warranty terms carefully. Coverage often depends on proper installation, routine maintenance, and adherence to manufacturer guidelines. Some warranties exclude damage from extreme weather or unauthorized modifications. Prompt registration and documentation of the installation process can streamline future claims.

A robust warranty reduces financial risk and supports long-term reliability. It signals the manufacturer’s confidence in their product and commitment to customer satisfaction. Telecom operators benefit from reduced downtime and predictable maintenance costs, strengthening the business case for solar-powered outdoor cabinets.

Warranty support acts as a safety net, protecting both the equipment and the investment over the system’s operational life.

Site & Environmental Factors

Placement

Proper placement of solar modules determines the efficiency and reliability of outdoor telecom cabinets. Engineers evaluate the site for optimal sunlight exposure, avoiding shade from trees, buildings, or other obstructions. Orientation plays a key role. Modules should face true south in the northern hemisphere and true north in the southern hemisphere to maximize energy capture. The tilt angle must match the site’s latitude for best results. Secure mounting on rooftops, poles, or ground structures helps prevent theft and damage. Site surveys identify potential hazards and ensure that the installation meets local regulations.

Tip: Regular site assessments help maintain optimal placement as surroundings change over time.

Climate Risks

Local climate risks can significantly impact the performance and longevity of solar modules in telecom applications. Engineers consider several environmental threats:

Wind gusts may lift modules from their supports. Rooftop installations offer more protection than elevated or tracking systems.

Hail can cause direct physical damage or leave debris that allows water to enter, compromising the system.

High temperatures reduce power generation efficiency by about 0.5% per degree Celsius increase. Heat also accelerates component aging and raises fire risk.

Moisture and high humidity degrade insulation and polymer parts, especially in hot, humid regions, shortening module lifespan.

Wind load design codes, such as Eurocode EN 1991-1-4 and ASCE 7-10, guide structural resilience. Computational fluid dynamics (CFD) simulations help engineers predict stresses and deformations during extreme weather.

These factors drive the selection of robust solar modules and protective enclosures, ensuring durability and consistent performance under local climate conditions.

Sustainability

Sustainability remains a top priority in solar module selection for telecom cabinets. Manufacturers and operators look for products that meet international safety and environmental standards. The following table highlights key certifications:

Certification/Standard | Relevance for Solar Modules in Telecom Cabinets |

|---|---|

IEC 61215 | Confirms durability and performance under standard test conditions. |

IEC 61730 | Certifies electrical, mechanical, and fire safety. |

CE Marking | Indicates compliance with safety, health, and environmental protection directives. |

FCC | Addresses electromagnetic interference in telecom environments. |

CB Scheme | Supports international acceptance of safety test reports. |

These certifications ensure that solar modules deliver reliable performance, meet regulatory requirements, and support environmental responsibility throughout their lifecycle.

Selecting the right solar module for outdoor telecom cabinets demands attention to both power output and environmental durability. Engineers maximize efficiency by choosing advanced photovoltaic technologies and weather-resistant materials. Key features include real-time monitoring, surge protection, and modular designs that support long-term reliability.

High efficiency panels and proper placement ensure consistent power.

Weatherproof construction and security features protect equipment from harsh conditions and theft.

Regular maintenance and smart monitoring reduce downtime and extend lifespan.

Expert Resource | Strengths | Considerations |

|---|---|---|

High efficiency, low maintenance | Higher upfront cost | |

Canadian Solar HiKu | Cost-effective, easy integration | Needs frequent cleaning |

Trina Solar Vertex | Robust design, high output | Larger size, more space |

Consulting with experts and following best practices helps operators match solar module choices to site-specific needs, ensuring reliable telecom service in any environment.

FAQ

What is the ideal IP rating for outdoor telecom solar modules?

An IP65 or higher rating works best. This rating ensures strong protection against dust and water jets. Operators should always check the enclosure’s certification before installation.

How often should technicians clean solar panels on telecom cabinets?

Technicians should clean panels at least twice a year. In dusty or polluted areas, more frequent cleaning may be necessary. Clean panels maintain maximum efficiency and extend system lifespan.

Which materials offer the best UV resistance for outdoor solar modules?

Polycarbonate (PC), fiberglass-reinforced polyester (FRP), and UV-stabilized ABS provide excellent UV resistance. These materials help prevent discoloration and brittleness, ensuring long-term reliability in harsh sunlight.

Can solar modules withstand hail and strong winds?

Manufacturers design quality modules to pass IEC 61215 and IEC 61730 tests. These tests verify resistance to hail impact and wind loads. Proper mounting and robust frames further enhance protection.

Do solar modules require special maintenance after severe weather?

After storms or extreme weather, technicians should inspect modules for cracks, loose mounts, or water ingress. Quick checks help prevent long-term damage and ensure continuous operation.

See Also

A Guide To Assessing Materials For Outdoor Telecom Cabinets

Essential Material Criteria Needed For Outdoor Telecom Cabinets

Tips For Selecting The Ideal Mount For Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA