Solar Modules + Smart Monitoring for Telecom Cabinets: Key Roles of Real-Time Power Monitoring & Fault Alert

Imagine managing a telecom cabinet in a remote area where reliable grid power does not exist. You face challenges such as cooling failures, harsh climates, and limited access for maintenance. A solar module delivers dependable energy, while smart monitoring systems give you real-time power data and instant fault alerts. With IoT-based tools, you shift from reactive responses to proactive maintenance, reducing costly downtime and ensuring continuous network service.

Key Takeaways

Solar modules provide reliable, clean power for telecom cabinets, especially in remote areas without grid access.

Smart monitoring systems offer real-time data and instant fault alerts, enabling proactive maintenance and reducing downtime.

Energy storage and climate-controlled cabinets protect batteries and ensure continuous operation during low sunlight or power fluctuations.

Remote access and IoT-based monitoring allow you to control and troubleshoot your sites from anywhere, saving time and costs.

Combining solar power with smart monitoring improves network uptime, cuts operational expenses, and supports environmental sustainability.

Solar Module Integration

Power Generation

You rely on solar module integration to ensure a stable power supply for telecom cabinets, especially in remote or off-grid locations. The process involves several key steps:

You use MPPT charge controllers with solar modules to maximize energy extraction, even when sunlight and temperature fluctuate.

You size solar modules with a 20% oversizing margin and plan for backup days, preventing power shortages.

You select modular designs with scalable rectifiers, adapting to different load scenarios.

You implement advanced MPPT algorithms, including AI-driven controllers, to maintain stable power delivery and extend equipment lifespan.

You deploy multiple MPPT trackers to handle shading and panel orientation variability, increasing energy yield and reliability.

Tip: Choose enclosures with high IP ratings, such as IP55 or IP66, to protect your solar module system from dust, water, and harsh environments.

Hybrid and off-grid solar solutions play a crucial role in reducing diesel consumption. By integrating solar, wind, battery storage, and diesel backup, you can cut diesel use by over 90%. These systems improve reliability, reduce generator failures, and minimize maintenance needs. Off-grid solar modules provide clean, low-cost energy, eliminating complex fuel logistics and lowering environmental impact.

Energy Storage

Energy storage systems complement solar module integration by stabilizing power supply and supporting peak load shifting. You store excess solar power in battery energy storage systems (BESS), ensuring continuous operation during nighttime or low sunlight. Intelligent energy management systems optimize scheduling between solar generation, storage, and backup sources, maximizing utilization and reliability.

Modular UPS systems work with solar modules and energy storage to address power fluctuations and grid instability. This combination guarantees uninterrupted operation of critical telecom equipment. You benefit from climate-controlled cabinets, waterproof seals, and filtered vents, which protect batteries from environmental damage and extend their lifespan.

Solar battery cabinets shield lithium-ion batteries from water, dust, and human interference.

Climate control features maintain stable temperatures, enhancing reliability.

Modular and secure designs support safe installation and maintenance.

Note: Arrange cabinet layout with equipment on top and batteries at the bottom for easier access and improved air circulation.

Smart Monitoring Systems

IoT-Based Monitoring

You gain a powerful advantage when you use IoT-based monitoring in your telecom cabinets. IoT sensors track critical parameters such as temperature, humidity, airflow, and power metrics in real time. This data flows securely through encrypted channels, using multi-factor authentication and open standards for seamless integration. You can view all sensor data on a centralized dashboard, which unifies information from multiple sources for comprehensive oversight.

Real-time alerts and automated incident handling, including auto ticketing and AI-driven anomaly detection, help you respond quickly and reduce downtime.

Predictive maintenance powered by AI analytics allows you to detect faults early and minimize repair times.

Modular and intelligent Power Distribution Units (PDUs) support scalable power management, overload protection, and energy efficiency.

Environmental monitoring sensors prevent equipment damage by maintaining optimal conditions inside the cabinet.

Security features, such as biometric locks and motion sensors, protect your equipment from unauthorized access.

You benefit from scalability, remote firmware updates, and flexible licensing, which adapt to your evolving infrastructure needs.

Detailed analytics, KPI tracking, and trend visualization support data-driven decisions that optimize operations and reduce costs.

Technologies like the ADAM-3600 Intelligent RTU, wireless I/O, and industrial gateways collect and transmit data efficiently. Wireless sensor networks and cellular routers provide robust connectivity, even in remote or harsh environments.

Tip: Use centralized dashboards to monitor all your sites at once, improving efficiency and reducing the risk of missed incidents.

Remote Access

Remote access transforms how you manage telecom cabinet power systems. You can monitor and control your sites from anywhere, which is essential for locations that are difficult to reach. Real-time automated control of multiple power sources improves reliability and prevents failures.

Remote monitoring reduces the need for physical site visits, saving you time and operational costs.

Integration with network management software gives you enhanced visibility and detailed alarm tracking.

Automated notifications and remote reboot capabilities speed up maintenance and response times.

Redundant connectivity ensures continuous operation, even if primary systems fail.

Cloud-based platforms offer real-time monitoring with customizable threshold alerts, centralized dashboards, and automated alarms. These features help you detect critical events immediately and facilitate rapid troubleshooting. Continuous sensor data collection supports predictive maintenance, reducing downtime and improving reliability across your network.

Note: Remote access not only boosts operational efficiency but also helps you scale your monitoring system as your network grows.

Power Monitoring

Data Analytics

You gain a strategic advantage when you leverage data analytics in telecom cabinet power monitoring. Modern systems track critical metrics such as power loads, voltage, current, temperature, humidity, and security status. These metrics provide you with a comprehensive view of your cabinet’s health and performance.

Electrical parameters: You monitor current, voltage, active power, apparent power, and energy consumption. These values help you maintain safe power distribution and prevent overloads.

Environmental factors: You track temperature, humidity, and airflow to protect sensitive equipment and ensure proper cooling.

Security monitoring: Intelligent locks and CCTV cameras with motion detection safeguard your infrastructure from unauthorized access.

Surge protection: You shield your equipment from voltage spikes and unexpected power events.

Real-time data collection enables you to respond immediately to abnormal conditions. Intelligent PDUs with IoT capabilities allow you to detect anomalies early, reducing downtime and costly repairs. Predictive maintenance models use historical sensor data and machine learning to forecast failures, helping you plan interventions before issues escalate.

Tip: Use centralized dashboards to visualize trends and key performance indicators (KPIs). This approach supports data-driven decisions and helps you optimize energy usage.

AI and machine learning algorithms analyze large volumes of data from your telecom power equipment. These tools predict failures, enable real-time monitoring and control, and dynamically adjust power consumption based on network demand. You benefit from fault detection and diagnostics that identify patterns and anomalies, improving the speed and accuracy of your response.

A novel energy efficiency metric, the utilization factor, allows you to evaluate telecommunication energy consumption independently of climate. Predictive models built from this data support diagnosis-oriented development, fault detection, and isolation of non-optimal energy management practices.

Metric | Purpose | Benefit |

|---|---|---|

Current (A) | Maintain safe load balance | Prevent overloads |

Voltage (V) | Ensure stable power delivery | Protect equipment |

Active Power (W) | Track real-time consumption | Manage capacity |

Apparent Power (kVA) | Assess total power demand | Improve power quality |

Energy (kWh) | Monitor cumulative usage | Identify efficiency trends |

Temperature/Humidity | Maintain optimal environment | Extend equipment lifespan |

Performance Optimization

You optimize telecom cabinet performance by using intelligent monitoring and remote management tools. Real-time tracking of power usage, anomaly detection, and remote control of power distribution allow you to shut down inactive devices and reduce energy waste.

You use AI-driven analytics to anticipate equipment failures and automate load balancing. This approach improves equipment lifespan and enhances overall performance.

You adopt green technologies, such as DC rectifier systems and hybrid renewable energy integration, to boost energy efficiency and support sustainability goals.

Surge and overload protection features prevent equipment damage and downtime, increasing reliability and uptime.

Remote power control reduces the need for on-site intervention, saving you time and resources.

Real-time power monitoring provides detailed, continuous data at both branch circuit and cabinet levels. You detect issues like overloaded circuits and phase imbalances early, allowing you to redistribute power and balance loads proactively. Monitoring identifies phantom loads and stranded power, helping you optimize power availability and reduce unnecessary consumption.

Note: Wireless power monitors simplify extensive monitoring without complex wiring, making it easier for you to maintain optimal power availability across multiple sites.

Integration with remote management tools speeds up maintenance response and enables centralized visibility. You benefit from a 31% faster mean time to repair and a reduction in maintenance touchpoints from eight to two. First-time fix rates improve due to more accurate alerts, and 24/7 proactive fault identification ensures continuous uptime.

Case studies show that telecom companies using intelligent PDUs and advanced monitoring systems achieve up to a 15% reduction in energy consumption and a 20% improvement in equipment uptime. Enhanced security features, including encrypted communications and multi-factor authentication, protect your critical systems from cyber threats and ensure stable operations.

Real-time monitoring and predictive analytics support proactive maintenance.

Automated fault detection and remote control minimize service interruptions.

Centralized portals provide visibility and control, improving operational efficiency.

You transform your telecom cabinet operations by combining data analytics and performance optimization. This approach delivers reliable, efficient, and secure power management, supporting your network’s growth and sustainability.

Fault Alerts

Detection

You depend on advanced fault detection systems to maintain the reliability of your telecom cabinets. Modern monitoring platforms use a combination of IoT sensors, edge computing, and AI-driven analytics to identify issues before they escalate. These systems continuously scan for anomalies in power, environment, and security, ensuring you catch problems early.

Common faults detected by these systems include:

Temperature spikes and humidity fluctuations, which can lead to overheating or moisture damage.

Power failures, voltage drops, and battery faults, such as abnormal temperature or voltage readings.

Cooling and ventilation system malfunctions, which threaten equipment stability.

Unauthorized access, vandalism, or theft, including copper wire and battery theft.

Environmental hazards like dust, water intrusion, and smoke.

Operational risks such as battery overheating or internal short circuits.

Sensors monitor temperature, humidity, smoke, water ingress, door status, and battery health. Real-time alerts and predictive analytics enable you to act before minor issues become major outages. AI-driven anomaly detection and edge computing enhance your ability to spot subtle trends, supporting proactive maintenance.

Tip: Regularly clean dust and debris from your cabinets. This simple step prevents overheating and electrical faults, extending equipment life.

Best practices for fault detection include:

Monitor power quality using standards like IEC 61000-4-30 and IEEE 1159 to catch voltage fluctuations and harmonics.

Use high-efficiency, modular rectifier modules for easy repairs and reduced downtime.

Implement remote monitoring with real-time status checks and automated alerts.

Employ AI-enabled predictive maintenance to analyze sensor data and forecast faults.

Maintain proper cooling and environmental controls for system reliability.

Integrate all power components into a single cabinet to minimize failure points.

Train your maintenance team to interpret alerts and diagnostic codes for rapid troubleshooting.

Schedule regular reviews of predictive maintenance data to optimize inspection intervals.

These strategies help you reduce maintenance costs by up to 35% and improve system uptime by about 25%. Automated alerts and remote monitoring can cut mean time to repair by around 35%.

Real-time fault alerts monitor key parameters such as voltage, temperature, power output, and battery health. Early detection prevents unexpected power interruptions, equipment failures, and thermal damage. Battery management systems track voltage, current, temperature, and state of charge, ensuring safe operation and preventing overcharging or thermal runaway.

Notification

Once your monitoring system detects a fault, it must notify you and your team instantly. Telecom software continuously captures logs, events, and internal counters, generating alerts for any abnormal behavior. These alerts use standardized formats based on KPIs, ensuring you receive clear and actionable information.

You benefit from multiple notification channels, including:

Email

SMS

Push notifications

Integration with incident management platforms

These methods guarantee that you and your team receive alerts wherever you are, allowing for immediate action. Platforms like ESTEL and INNSPECT support customizable notifications, so you can tailor alerts to your operational needs. Instant alerts notify you about network issues, enabling fast maintenance responses and minimizing downtime.

Note: Automated notifications not only speed up your response but also reduce the risk of missed incidents, supporting continuous network reliability.

Outdoor telecom cabinets support low-latency communication between field equipment and control centers. This setup allows near real-time alerts for anomalies such as temperature deviations or power failures. Smart monitoring systems notify your maintenance teams before failures occur, minimizing truck rolls and enabling faster response times.

Rule-based notifications and real-time data collection enhance operator awareness. You can interact with remote clients and field technicians, ensuring everyone stays informed and ready to act. Built-in safeguards like overload protection and thermal management help you avoid critical failures, while modular design and real-time monitoring further reduce operational risks.

Notification Channel | Speed | Customization | Use Case |

|---|---|---|---|

Fast | High | Routine alerts, reports | |

SMS | Instant | Moderate | Critical faults, urgent action |

Push Notification | Instant | High | Mobile alerts, on-the-go teams |

Incident Platform | Real-time | High | Workflow integration, escalation |

You ensure operational continuity by responding to alerts quickly. Real-time notifications empower you to prevent outages, protect assets, and maintain high service levels across your telecom network.

Operational Benefits

Uptime

You achieve higher network uptime when you combine solar modules with smart monitoring in your telecom cabinets. Real-time monitoring and predictive analytics help you spot issues before they cause outages. For example, using 200W solar modules with smart monitoring provides a larger energy buffer, absorbs load spikes, and extends battery life. This setup ensures stable power even during cloudy weather or sudden demand increases. You can handle maintenance remotely, reducing site visits and minimizing downtime. In Canada, hybrid PV/wind/diesel/battery systems led to a 58% cost reduction and a 25% decrease in downtime, showing how these solutions keep your network running smoothly.

Aspect | Impact of 200W Solar Modules and Smart Monitoring |

|---|---|

Energy Buffer | Handles load spikes and weather fluctuations |

Real-Time Monitoring | Enables proactive maintenance and fewer outages |

Maintenance & Reliability | Simplifies upkeep and reduces failures |

Environmental Adaptation | Maintains performance in harsh conditions |

Battery Life Extension | Reduces deep discharges and extends lifespan |

Cost Savings

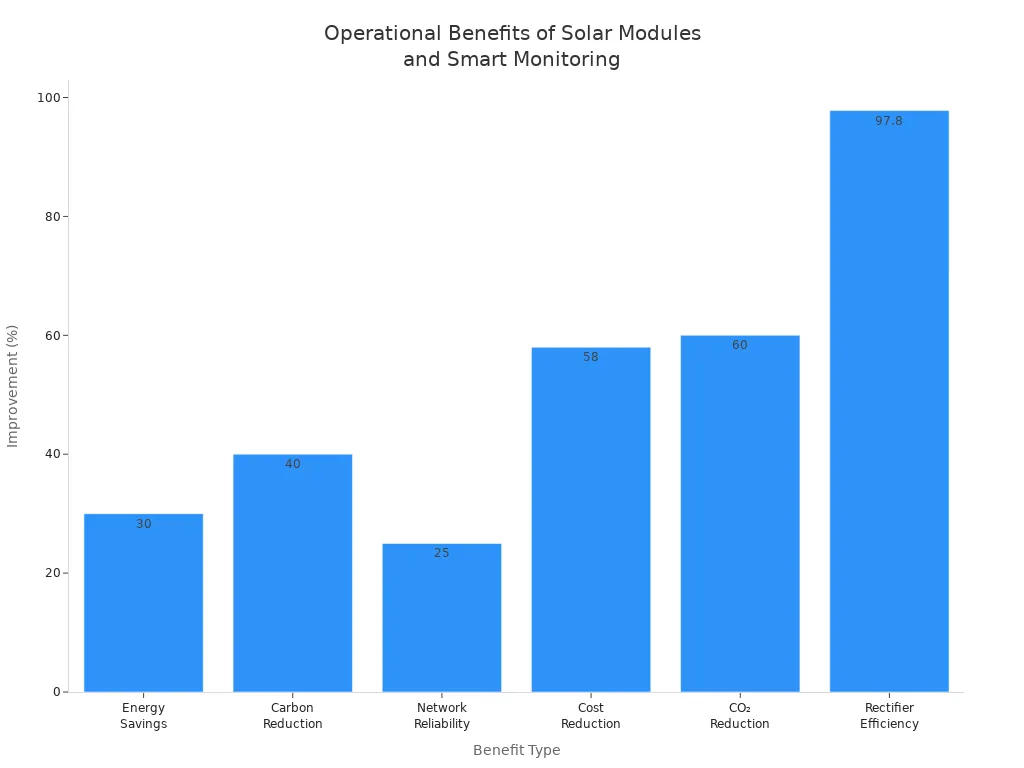

You save significantly on operational costs by deploying solar modules and smart monitoring. HCI Energy’s Hybrid Power Shelter, which integrates solar, wind, batteries, and generators with smart monitoring, delivered over $650,000 in savings at telecom tower sites. You avoid expensive repairs and reduce technician dispatches by using predictive maintenance and remote monitoring. Smart cabinets help you cut energy consumption by up to 30% and lower carbon emissions by 40%. Hybrid solar-diesel systems also reduce generator runtime by up to 80%, slashing fuel and maintenance expenses.

Reliability

You boost reliability with smart monitoring and solar integration. Real-time alerts let you respond instantly to power failures, while predictive maintenance reduces outages and extends equipment life. Sensors track power quality and environmental conditions, protecting your assets from damage. For instance, ESTEL’s AI-driven monitoring systems improved equipment uptime by 20% and cut maintenance costs by 30%. Operators like T-Mobile and Vodafone now run on 100% renewable energy, achieving major reductions in carbon emissions and improved network reliability. With these tools, you ensure continuous service and protect your telecom infrastructure from unexpected failures.

You gain significant advantages by integrating solar module technology with smart monitoring in telecom cabinets.

Real-time power monitoring and fault alerts help you prevent outages, reduce costs, and improve energy efficiency.

Automated systems optimize energy use, support predictive maintenance, and increase energy independence.

You lower your environmental impact by reducing fossil fuel reliance.

Looking ahead, you will see modular power systems, advanced lithium-ion batteries, and AI-driven management platforms become standard. These innovations support reliable, scalable, and sustainable telecom networks.

FAQ

How do solar modules improve telecom cabinet uptime?

Solar modules provide a stable, renewable power source. You reduce your reliance on the grid or diesel generators. This setup ensures your telecom cabinets stay online during outages or fuel shortages.

What types of faults can smart monitoring detect?

Smart monitoring detects power failures, temperature spikes, humidity changes, battery faults, and unauthorized access. You receive instant alerts for these issues, allowing you to act quickly and prevent equipment damage.

Can you access monitoring data remotely?

Yes, you can access real-time data from any location. Cloud-based dashboards and mobile apps let you monitor, control, and troubleshoot your telecom cabinets without visiting the site.

Tip: Set up automated alerts on your dashboard. You will never miss a critical event.

How does predictive maintenance save you money?

Predictive maintenance uses sensor data and analytics to forecast equipment issues. You schedule repairs before failures occur. This approach reduces emergency repairs, lowers maintenance costs, and extends equipment life.

See Also

Solar Powered Energy Storage Solutions For Telecom Cabinets

Best Practices To Monitor Outdoor Telecom Cabinets Effectively

ESTEL’s Intelligent Microgrid Energy Storage For Telecom Cabinets

Grid-Tied Solar Inverter And Battery Setup For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA