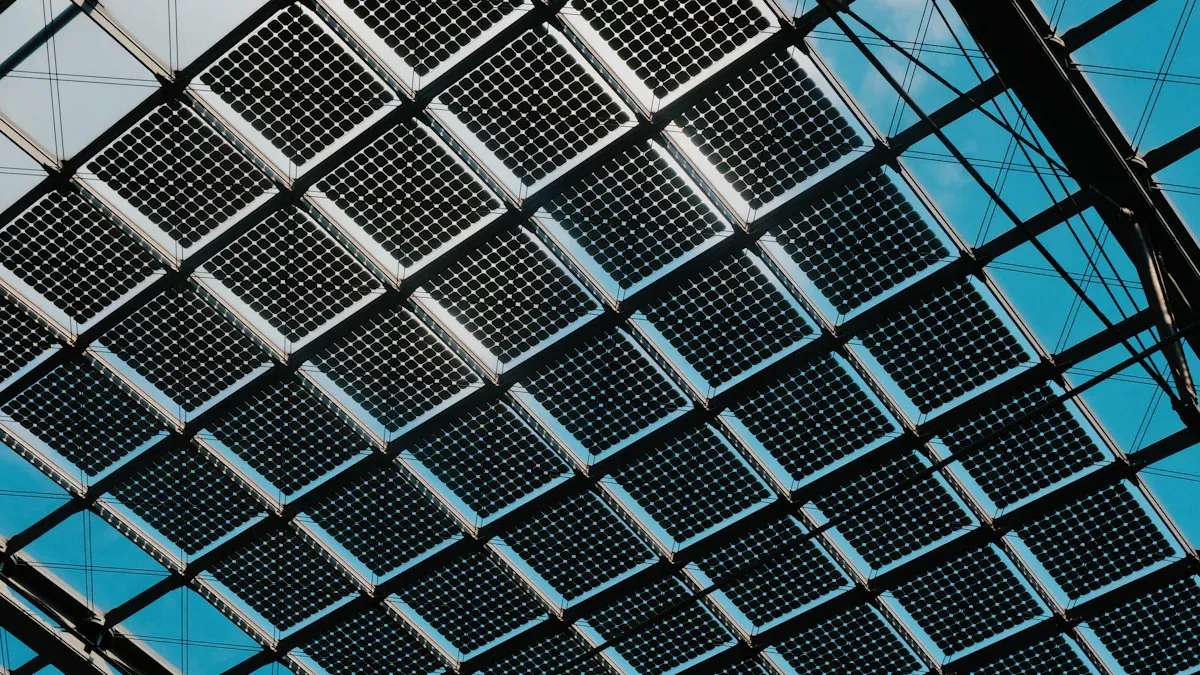

Steel Structure for PV Panel acceptance: 5 key standards including verticality, wind resistance test, and grounding resistance

When you check Steel Structure for PV Panel acceptance, look at five main standards. These are verticality, wind resistance, grounding resistance, material and code compliance, and installation quality. Each standard helps keep your solar system safe and working for a long time. For example:

Locking fasteners stop parts from shaking loose.

Through-bolting modules help them stand up to strong wind.

Pressure ratings stop glass from breaking in wind or snow.

Metal wire clips hold wires tight and safe.

Strong enclosures protect electric parts from bad weather.

Use these standards as a checklist for good performance.

Key Takeaways

Check verticality closely to make sure your PV panel stands straight. This helps the structure stay strong and not fall in wind or rain.

Test wind resistance by picking good materials and smart designs. These help the system handle strong winds and shaking. This stops damage and helps the system last longer.

Ground your steel structure the right way to keep people and equipment safe from electric shocks. Always test grounding resistance to stop system failures.

Use the correct steel and materials that meet industry rules. Pick ones that do not rust so your structure stays safe and lasts a long time.

Follow a careful installation checklist and check your system often. This helps you find problems early, keep things safe, and make sure your system works well for many years.

Steel Structure for PV Panel: Verticality

Importance

Verticality means you install the support brackets so they stand straight up, perpendicular to the ground. When you build a Steel Structure for PV Panel, verticality keeps the system strong and stable. If you set the brackets vertically, the panels get the best support and can handle heavy wind or rain. This setup also helps the panels catch more sunlight, which boosts energy production. When you follow the design and keep the brackets vertical, you protect the structure from damage and make sure it lasts for years. You also help the whole system carry weight safely, which prevents bending or breaking.

Tip: Always check verticality during installation. This step protects your investment and keeps your PV system working well.

Measurement

You can measure verticality with simple tools and careful checks. Here are the most common steps:

Tie a heavy object to a thin nylon rope to make a plumb line.

Hold the top of the rope about 10 meters from the steel pole or bracket.

Stand about 20 centimeters away and look to see if the plumb line matches the pole.

Check from four directions: north, south, east, and west.

If the pole lines up with the plumb line in every direction, you have good verticality.

Some installers also use a level meter to check the foundation before putting up the brackets. If you find a problem, adjust the pole or bracket until it stands straight.

Tolerances

Most building codes and PV standards set a small range for how much a bracket can lean. Usually, the tilt should not go past 2 millimeters per meter of height. If your Steel Structure for PV Panel does not meet this tolerance, you must fix it before moving forward. Always check the design documents for the exact numbers. If you find a bracket out of spec, adjust or reinstall it right away. Keeping within tolerance helps your PV system stay safe and last longer.

Wind Resistance

Wind Uplift Test

Wind uplift tests check if your Steel Structure for PV Panel can stand up to strong winds. You need to look at a few important things during these tests:

Wind load and direction: Test the structure from different wind angles, like 45°, 135°, and 180°. These directions push the hardest.

Panel tilt and shape: The angle of your panels changes how wind hits them. Panels tilted less than 45° follow one set of rules. Steeper panels use different rules.

Exposure and pressure: Standards like ASCE 7-22 and JIS C 8955 give you numbers to use for pressure and exposure.

Material strength: Make sure the steel bends but does not break. It should take sudden wind gusts without failing.

Corrosion and fatigue: Check that your materials do not rust or wear out over time.

Testing methods: Use wind tunnel tests or computer models to see how your structure acts in wind.

The MIS 3002: 2025 Solar PV Installation Standard says a qualified person or engineer must check your structure for wind uplift. You also need to use the right fixing methods. Make sure your roof can safely move wind loads.

Note: Always follow local building codes. Use certified mounting systems if you can.

Wind Vibration

Wind does not just push; it shakes things too. Wind vibration can make your structure move or bend. Over time, this can cause it to break. You need to check wind vibration coefficients. These numbers show how much your structure shakes in the wind. Building codes now say you must use these numbers in your design. If you ignore vibration, your structure could get weak or break suddenly. Use strong, bendy steel and design your system to handle shaking. Modern designs use wind tunnel tests and computer models to lower vibration risks.

Anti-Seismic

If you live where earthquakes happen, you must follow anti-seismic rules for your Steel Structure for PV Panel. Here is a quick guide:

Aspect | Requirement / Recommendation |

|---|---|

Seismic Load Standards | Follow ASCE 7 and International Building Code (IBC) for seismic loads. |

Material Requirements | Use high-strength, corrosion-resistant steel like galvanized or stainless steel. |

Structural Components | Pick brackets and parts made for seismic resistance. |

Installation | Hire certified professionals for installation. |

Local Regulations | Always check local codes and rules for seismic safety. |

Design and Verification | Use advanced modeling tools and get expert engineering advice. |

Maintenance | Inspect regularly to prevent rust and keep the system reliable during earthquakes. |

Tip: Corrosion resistance is just as important for earthquake safety as it is for wind resistance. Always pick materials that last.

Grounding Resistance

Electrical Safety

Grounding resistance is very important for safety. When you ground your Steel Structure for PV Panel the right way, you keep people and equipment safe from electric danger. Good grounding does many things. It stops electric charge from building up. This helps stop sparks or arcing. It gives fault currents a safe way to go into the earth. This lowers the chance of electric shock. It protects your PV system from damage during faults or surges. Extra current can flow away safely. It keeps voltage steady so your equipment does not get too much power. This helps you save money because your equipment will not break as often. You will also have less downtime. Studies show grounding resistance changes shock voltages and earth fault currents. You must guess earth currents and pick the right grounding electrodes to stop shock danger. Good grounding is also needed when you connect DC microgrids with AC networks.

Testing Methods

You must test grounding resistance to make sure your system is safe. The best way is the 3-Point Dead Fall of Potential test. This test uses a Megger-type resistance meter and two extra ground rods. You measure resistance from different sides and find the average. This test works best for small or medium systems. For bigger systems, you can use a Clamp-On Ground Rod Tester. This tool is quicker and easier but not as exact. You clamp it on the ground cable and check the number. If the number is good, your system passes. Multimeters can give you a rough idea, but they are not good enough for final checks. For solar panels, grounding resistance should be under 4 ohms to be safe.

Tip: Always follow safety rules and ask a professional for help when you test grounding systems.

NEC Compliance

The National Electrical Code (NEC) has strict rules for grounding in PV systems. Every photovoltaic module needs its own ground bond. You cannot just use mounting hardware because coatings on panel frames might block electric contact. Use lugs or screws that break through the coating for a good connection. Some panels have special holes for bolts, nuts, and star washers. Make sure all connections stay tight and do not come loose during maintenance. NEC Article 250 has many rules about grounding and bonding. Always check the newest code before you install or check your system.

Material and Code Compliance

Material Specs

You must pick the right materials for your Steel Structure for PV Panel. There are rules from around the world that tell you what to use. The table below lists common materials, where they go, and the rules to follow:

Material Type | Application Areas | Relevant Standards and Specifications |

|---|---|---|

ASTM A572/A572M-15 Grade 50 steel | Columns, sloped beams, purlins | ASTM A572/A572M-15 (High-Strength Low-Alloy Structural Steel) |

ASTM A36/A36M-08 carbon steel | H-shaped piles, braces, brackets, joints | ASTM A36/A36M-08 (Carbon Structural Steel) |

Cold-formed steel | Columns, beams, purlins | AISI S100-16W/S1-18 (Cold-Formed Steel Members) |

Welding materials | Welded connections | AWS A5.5/A5.5M (Welding Electrodes) |

Bolts | General and pressure block bolts | ASTM A307 Grade A, 304 stainless steel (A2-70) |

Corrosion protection coatings | All structural steel | EN ISO 12044, EN ISO 14713, ISO 1461 (Galvanizing, Coating) |

Fabrication and installation | Shop manufacture and erection | AISC 303-16 (Standard Practice for Steel Buildings and Bridges) |

Always check if your materials match these rules. Using the right steel and bolts helps your structure stay strong and safe for a long time.

Anti-Corrosion

Rust can make your steel structure weak as time goes by. You can keep your system safe by using some good ways:

Put on special coatings and covers to stop water and chemicals.

Use capsules that let out blockers when rust starts.

Pick strong steel for tough or seaside places.

Test steel with salt spray and sticky coatings to make sure they hold.

Add weatherproof layers to stop sun and scratches.

Check coatings often and fix them when needed.

These steps help your Steel Structure for PV Panel fight rust and damage. Your system will last longer and need less fixing.

Tip: Check your anti-corrosion layers often and fix them fast to keep them working well.

Documentation

You need to keep good records to show you follow the rules. Most building offices and inspectors will want:

Drawings stamped by a licensed engineer, with math and details.

Full plans for both the structure and the electric parts.

Proof you follow codes like the International Building Code (IBC), National Electrical Code (NEC), and local fire rules.

Papers that show design, size, place, system ratings, tests, and how you put it together.

Permits and reports from checks.

Records of working with fire crews and power companies, including paths and shut-off signs.

Good records show your system is safe and legal. They also help you fix problems quickly if something goes wrong.

Installation and Inspection

Installation Checklist

A good installation helps your PV system work well. Use this checklist to help you:

Site Preparation: Make sure the sun shines on your site. Remove anything blocking the sun. Check the ground and get all needed permits.

Foundation Selection: Pick the best foundation for your ground and weather. Test the soil before you start.

Frame Assembly: Check all parts for damage. Lay out the frame pieces. Connect them with bolts or welds. Add braces. Make sure the frame is flat and straight.

Panel Mounting: Use the right hooks or brackets. Level the panels with special hooks. Bolt rails tightly. Fix panels with clamps. Leave space between panels for air and no shade. Run cables neatly and seal them from water.

Safety Measures: Wear a helmet, gloves, and safety shoes. Keep your work area clean. Use the right tools. Turn off power before working with wires.

Compliance: Follow all local building rules. Keep drawings and permits ready to show.

Material Selection: Use aluminum or galvanized steel brackets. This stops rust and helps your Steel Structure for PV Panel last longer.

Maintenance Checks: Check and tighten bolts. Look at cables. Test how the system works often.

Tip: A good checklist helps you not forget steps. It also helps your system last longer.

Inspection Points

You need to check your work to keep it safe and strong. Look at these important things:

Corrosion: Check joints, base plates, and places that touch dirt or water. Look with your eyes and use special tests.

Bolt Tightening: Use a torque wrench to check bolts. Tighten bolts again in windy places. Change any broken fasteners.

Fastener and Bracket Integrity: Make sure all fasteners are tight. Check that anti-loosening devices are there. Do tension and swing tests.

Structural Assessment: Look for cracks, bent parts, or things not lined up. Use vibration tests to find hidden problems.

Safety: Wear PPE like harnesses, gloves, and hard hats. Follow safe work rules and electric safety steps.

Qualified Personnel: Only trained and certified people should do inspections.

Record-Keeping

Good records help you follow rules and fix things later. Write down all checks, repairs, bolt tightness, and rust fixes. Keep drawings, permits, and reports safe. Change your maintenance plan as you learn more about your system. How often you check depends on your site, design, and how your system works. Change your schedule as you see what works best for your Steel Structure for PV Panel.

Good records help you show you followed rules. They also make it easier to use your warranty.

If you follow the five key standards for Steel Structure for PV Panel acceptance, you keep your investment safe and help your system work well for many years. Field studies show that bad design, weak materials, or not taking care of your system make it break faster and cost more to fix.

Systems that get checked often and use strong steel frames last longer. They can also handle bad weather better.

Using better fasteners and making the structure stronger stops many problems.

Keeping good records and following the rules makes your installation safe and dependable.

Always ask experts for help to keep your system safe and working longer.

FAQ

What happens if my steel structure fails the verticality check?

You must realign or reinstall the bracket. If you skip this step, your panels may not work well. Poor verticality can cause stress, bending, or even collapse. Always fix alignment issues before moving forward.

How often should I inspect my PV steel structure?

You should inspect your system at least once a year. After strong storms or earthquakes, check for damage right away. Regular checks help you find rust, loose bolts, or other problems early.

Can I use any type of steel for my PV panel structure?

No. You need to use steel that meets industry standards like ASTM A36 or A572. These types resist bending and rust. Using the wrong steel can shorten your system’s life and may break building codes.

Why is grounding resistance so important for PV systems?

Good grounding protects you from electric shock and equipment damage. It lets fault currents flow safely into the earth. Without proper grounding, you risk fire, injury, or system failure.

See Also

Essential Structural Design Elements For ESTEL Outdoor Telecom Cabinets

Crucial Material Specifications Needed For Outdoor Telecom Cabinets

Important Design Criteria For ESTEL Outdoor Base Station Cabinets

A Comprehensive Look At ESTEL Outdoor Telecom Cabinet Structures

Key Durability Factors For Long-Lasting Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA