Steel Structure for PV Panel procurement decision tree focusing on cost, lifespan, and service weight prioritization

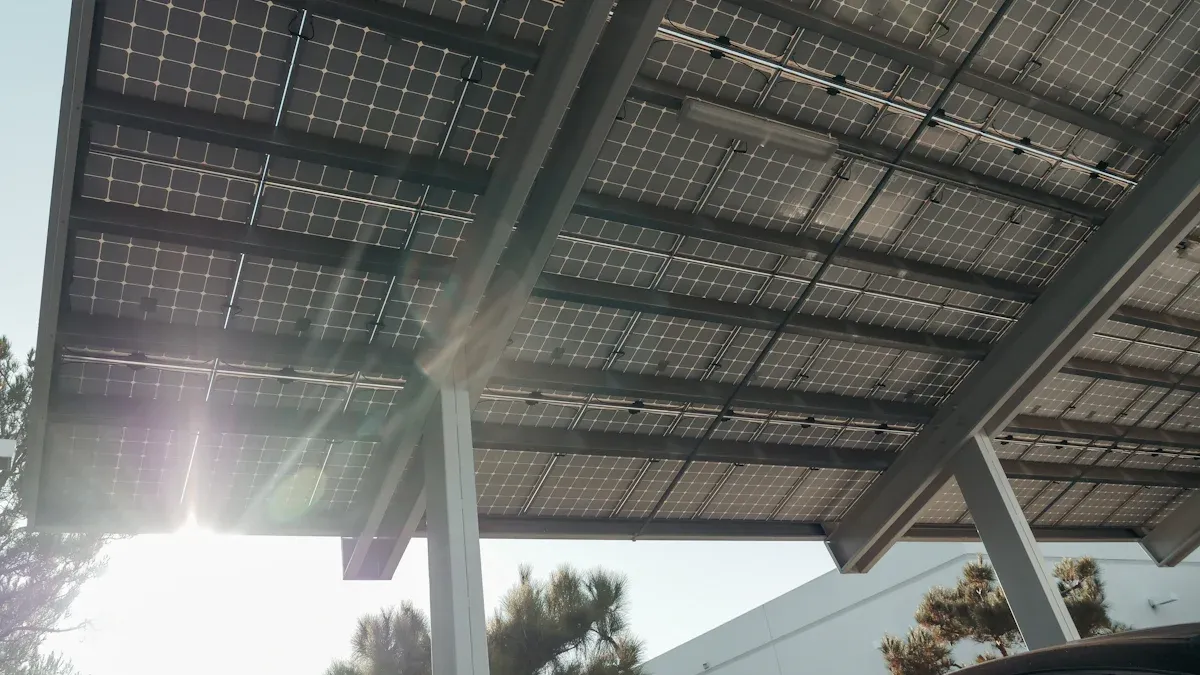

Selecting the right Steel Structure for PV Panel installations shapes both the immediate and long-term value of a project. Industry research shows that durable materials such as galvanized steel reduce operation and maintenance costs over time by minimizing failures and extending service life.

Galvanized steel resists corrosion and harsh weather, supporting structural integrity for years.

Its thermal properties help prevent overheating, which maintains panel efficiency and system longevity.

Prioritizing robust steel components ensures lower maintenance frequency and cost, making them a preferred choice for reliable energy infrastructure.

Key Takeaways

Choose steel structures by balancing cost, lifespan, and service weight to get the best value and performance.

Investing in high-quality, corrosion-resistant steel reduces maintenance costs and extends the structure's life.

Lightweight steel frames work best for rooftops, while heavier, stronger steel suits ground-mounted systems.

Use a clear decision process that includes life-cycle cost analysis and project-specific needs for smarter procurement.

Regular maintenance and protective coatings keep steel structures safe and efficient for many years.

Key Criteria

Cost

Cost remains a primary factor in any procurement decision for a Steel Structure for PV Panel. Project managers often evaluate both initial purchase price and long-term expenses. Material selection, fabrication complexity, and transportation all influence upfront costs. Galvanized steel, for example, may require a higher initial investment but reduces maintenance and replacement expenses over time. Life-cycle cost analysis helps teams compare options by considering not only the purchase price but also operation, maintenance, and potential downtime. By focusing on total cost of ownership, decision-makers can avoid unexpected financial burdens during the system’s lifespan.

Lifespan

Lifespan determines how long a Steel Structure for PV Panel will reliably support solar modules. Durability depends on material quality, protective coatings, and resistance to environmental stressors. Galvanized steel and corrosion-resistant alloys extend service life, especially in harsh climates. Regular inspections and preventive maintenance further increase longevity. A longer lifespan reduces the frequency of replacements and minimizes disruptions to energy production. Teams should prioritize structures with proven durability records and certifications that meet or exceed industry standards.

Service Weight

Service weight directly affects design and installation strategies for steel structures. Lightweight frames suit rooftop installations, where minimizing load prevents structural damage and speeds up assembly. Ground-mounted systems require heavier steel and robust foundations to withstand wind and snow. The choice of alloy, such as Q235B or Aluminum Alloy AL6005-T5, balances strength, weight, and corrosion resistance. Protective coatings and modular designs enhance adaptability and simplify installation. The table below summarizes how service weight influences design and installation across different environments:

Aspect | Influence on Design and Installation |

|---|---|

Service Weight | Drives the need for lightweight yet strong steel alloys and optimized geometries to reduce mass, especially for rooftops to avoid overloading structures. |

Rooftop Installations | Require lightweight steel frames to ease transportation, handling, and faster assembly, reducing labor and protecting roof waterproofing. |

Ground-Mounted Systems | Use heavier steel pipes and robust foundations to withstand environmental loads like wind and snow, requiring substantial foundation work. |

Alloy Selection | Q235B steel offers high strength for large/heavy arrays but is heavier and needs galvanization; Aluminum Alloy AL6005-T5 is lighter, corrosion-resistant, suited for rooftops and coastal areas. |

Corrosion Resistance | Essential in humid/coastal environments; protective coatings and corrosion-resistant alloys maintain structural integrity. |

Environmental Adaptation | Customization such as marine-grade steel for coastal sites or reinforced frames for snowy regions enhances durability and safety. |

Modular Design | Prefabricated, modular steel components support adaptability, scalability, and ease of installation across diverse environments. |

Steel Structure for PV Panel Selection

Project Needs

Every PV panel project begins with a clear understanding of its unique requirements. Project teams assess several factors before selecting a Steel Structure for PV Panel systems:

Site and foundation conditions: Soil analysis determines the best foundation type, such as independent or strip foundations, while avoiding raft foundations in poor soil.

Steel type and structural form: Light-duty structural steel, including round or angle steel, matches the project’s strength and simplicity needs.

Mechanical properties: High tensile and yield strength reduce material volume and cost. Toughness and fatigue resistance ensure the structure withstands wind and repeated loads.

Corrosion resistance: Steel must resist corrosion to guarantee a service life of over 20 years.

Fabrication and installation: Factory-processed components with precise drilling and galvanizing simplify installation and reduce on-site rusting.

Compliance: Structures must meet local building codes and standards for safety and reliability.

Structural design: The design must account for dead, live, wind, and seismic loads, including lateral bracing for taller structures.

Material availability: Readily available steel supports project timelines and cost control.

Note: Local climate, such as humidity, wind, and temperature swings, also shapes the choice of steel and coatings to ensure long-term durability.

Criteria Prioritization

Decision-makers must balance cost, lifespan, and service weight to achieve optimal results. Multi-Criteria Decision-Making (MCDM) frameworks, such as the Best Worst Method (BWM) combined with TOPSIS, help teams assign weights to each criterion based on project goals. For example, a coastal installation may prioritize corrosion resistance and lifespan, while a rooftop project may focus on service weight. Teams often use life-cycle cost analysis to compare options, considering both initial and long-term expenses.

Tip: Assigning clear priorities to each criterion ensures the selection process aligns with project objectives and site-specific challenges.

Structure Options

Several steel structure types serve PV panel mounting needs. The main options include galvanized steel, stainless steel, and cold-formed steel. Each material offers distinct advantages:

Feature | Galvanized Steel | Stainless Steel | Cold-Formed Steel |

|---|---|---|---|

Cost | Affordable | Higher upfront cost | Cost-effective |

Corrosion Resistance | Moderate (most climates) | Excellent (extreme conditions) | Good (with coatings) |

Durability | Good | Exceptional | High |

Environmental Impact | Lower CO2 emissions | Slightly higher CO2 emissions | Moderate |

Galvanized steel remains popular for outdoor installations due to its balance of cost and durability. Stainless steel suits harsh environments but increases initial investment. Cold-formed steel combines strength and affordability, making it suitable for diverse mounting systems, including ground, rooftop, pole-mounted, and floating solar arrays.

Cost Analysis

Cost analysis extends beyond the purchase price. Teams evaluate the total life-cycle cost, which includes manufacturing, installation, operation, and maintenance. Steel structures often require a higher initial investment, especially when using prefabricated components and bolted connections. However, these structures offer lower maintenance costs over time, resulting in long-term savings. Design optimization and the use of recyclable materials further reduce environmental impact and future expenses.

Operation and maintenance (O&M) costs account for the largest share of total life-cycle cost, sometimes reaching 74%.

Scheduled inspections and efficient cleaning routines help minimize O&M expenses.

Investing in high-quality steel and protective coatings reduces failure rates and replacement needs.

Lifespan Review

The expected service life of a Steel Structure for PV Panel depends on material grade and protective coatings. High-grade steel enhances durability and resists wear. Protective coatings, such as zinc-dust primers and phenolic layers, significantly improve corrosion resistance, especially in coastal or polluted environments. Laboratory and field tests confirm that these coatings extend service life by at least 10%. Stainless steel provides the highest corrosion resistance but at a premium price. Galvanized steel may require re-coating every 5 to 7 years in aggressive climates. Selecting the right combination of steel grade and coating ensures structural safety and efficiency for over two decades.

Weight Assessment

Service weight influences both design and installation. Lightweight steel frames suit rooftop projects, reducing load on existing structures and simplifying assembly. Ground-mounted systems require heavier steel and robust foundations to withstand wind and snow. The choice of alloy, such as Q235B or aluminum alloy, balances strength and weight. Modular, prefabricated designs further ease transportation and installation. Teams must consider local climate, as wind and snow loads affect the required weight and strength of the structure.

Final Choice

The final selection process integrates all criteria using a structured decision tree:

Define project needs and site conditions.

Assign priorities to cost, lifespan, and service weight using an MCDM framework like BWM-TOPSIS.

Shortlist structure options based on material properties, durability, and compliance with local codes.

Conduct a life-cycle cost analysis, factoring in O&M, maintenance, and replacement intervals.

Review lifespan data, focusing on steel grade and protective coatings.

Assess service weight for installation and structural safety.

Ensure regulatory compliance and adaptability to local climate.

Select the Steel Structure for PV Panel that best balances all priorities.

Teams that follow this systematic approach achieve optimal structural integrity, economic feasibility, and long-term reliability. Operation and maintenance considerations, along with regulatory compliance, remain central to sustainable project success.

Practical Scenarios

Cost-Focused

A solar developer in a semi-arid region prioritized minimizing upfront expenses for a new installation. The team selected a traditional steel structure without advanced coatings, aiming to reduce initial costs.

Over time, the structure showed signs of corrosion due to exposure to humidity and temperature swings.

Maintenance costs increased as the team needed to address rust and structural wear.

The project experienced occasional downtime for repairs, impacting energy output.

Focusing only on short-term savings led to higher operational costs and reduced reliability. Lifecycle cost analysis later revealed that investing in higher-quality steel, such as ESTEL, would have minimized replacements and repairs, resulting in better long-term performance and lower total cost of ownership.

Lifespan-Focused

A utility-scale PV project near a coastal area faced harsh environmental conditions, including salt-laden air and high humidity. The project team prioritized durability and selected ESTEL steel structures with advanced corrosion-resistant coatings.

The steel structure maintained integrity over many years, with minimal maintenance required.

The system delivered consistent energy output, even in challenging weather.

The initial investment proved worthwhile, as the structure avoided frequent repairs and replacements.

This scenario demonstrates that prioritizing lifespan and quality materials ensures reliable operation and maximizes energy production. Industry feedback confirms that such choices lead to improved reliability and long-term value.

Weight-Focused

A commercial building owner planned a rooftop solar array and focused on minimizing service weight to protect the existing structure.

The team conducted a structural analysis to ensure the roof could support the additional load.

Lightweight steel alloys and modular components simplified installation and reduced labor time.

Compliance with building codes and engineering approvals ensured safety and regulatory adherence.

Prioritizing service weight required careful planning and professional evaluation, but it enabled a safe, efficient, and cost-effective installation. Streamlined permitting and inspection processes further reduced project costs and timelines.

A well-structured procurement process ensures project teams balance cost, lifespan, and service weight for optimal results. Teams should apply the outlined decision tree, review project-specific needs, and consult industry experts when necessary. By following this approach, organizations can achieve reliable performance and long-term value.

For successful outcomes, prioritize informed, structured procurement for every Steel Structure for PV Panel project.

FAQ

What factors most influence the total cost of a steel structure for PV panels?

Material quality, fabrication methods, and protective coatings drive costs. Teams also consider transportation, installation, and long-term maintenance. Life-cycle cost analysis helps identify the most cost-effective option for each project.

How does service weight affect rooftop solar installations?

Service weight impacts structural safety and installation speed. Lightweight steel frames reduce load on existing roofs. This choice helps prevent damage and simplifies assembly, especially for older buildings.

Why is lifespan important when selecting steel structures for PV panels?

A longer lifespan reduces replacement frequency and maintenance needs. Durable materials and protective coatings ensure the structure supports solar panels reliably for decades, maximizing energy production and investment returns.

Do steel structures for PV panels require regular maintenance?

Yes. Teams schedule inspections and cleaning to prevent corrosion and structural wear. Regular maintenance extends service life and ensures safe, efficient operation.

Tip: Use galvanized or coated steel to minimize maintenance frequency.

See Also

Essential Structural Design Elements For ESTEL Outdoor Telecom Cabinets

Comparing Durability Of Various Outdoor Communication Cabinets

A Comprehensive Look At ESTEL Outdoor Telecom Cabinet Structures

Guidelines For Assessing Materials Used In Outdoor Telecom Cabinets

Material Specifications Needed For Outdoor Telecom Cabinet Construction

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA