Steel Structure for PV Panel: Choosing Between Q235 and Q355 Based on Strength, Cost, and Durability

If you want the best balance of strength, cost, and durability for a Steel Structure for PV Panel, you should usually choose Q355 for demanding or long-term projects. For most budget-focused installations, Q235 offers reliable performance.

Here is a quick comparison to help you decide:

Property | Q235 | Q355 |

|---|---|---|

Strength | Standard | High |

Cost | Lower | Higher |

Durability | Good (with coating) | Better (with coating) |

Key Takeaways

Q355 steel offers higher strength and better durability, making it ideal for heavy loads and harsh environments.

Q235 steel costs less and is easier to weld, fitting well with budget projects and standard installations.

Both steels need protective coatings like hot-dip galvanizing to resist corrosion and last outdoors.

Choosing Q355 can reduce installation weight and long-term maintenance costs despite its higher price.

Match your steel choice to your project’s load, environment, and budget for the best balance of performance and cost.

Quick Comparison

Key Differences

When you choose between Q235 and Q355 for a Steel Structure for PV Panel, you need to look at several important factors. Q355 gives you higher strength and better performance in demanding conditions. Q235 offers good weldability and lower cost, which makes it a popular choice for many standard projects.

Strength: Q355 has a much higher yield and tensile strength than Q235. This means Q355 can handle heavier loads and more stress without bending or breaking.

Durability: Q355 keeps its toughness even at low temperatures and resists impact better. Q235 works well for general use but does not perform as well in harsh environments.

Corrosion Resistance: Q355 contains more alloying elements, which help it resist corrosion. However, both steels need protective coatings for outdoor use.

Weldability: Q235 has lower carbon content, so you can weld it more easily. Q355 needs careful welding procedures because its higher carbon content increases the risk of cracking.

Cost: Q235 costs less and fits tight budgets. Q355 costs more because of its higher strength and alloy content.

💡 Tip: If your project faces heavy loads, strong winds, or harsh weather, Q355 is usually the safer choice. For smaller or budget projects, Q235 often meets your needs.

Mechanical Properties Table

Property | Q235 Steel | Q355 Steel (S355) |

|---|---|---|

Yield Strength | ~235 MPa (decreases with thickness) | ≥355 MPa |

Tensile Strength | ~235 MPa | ≥355 MPa |

Impact Toughness | Lower at low temps | Better, maintains toughness at low temps |

Alloying Elements | Mainly C, Si, Mn, S, P | Includes V, Ti, Nb for added strength |

Plasticity & Weldability | Good | Good, but needs careful welding |

Corrosion Resistance | Standard carbon steel | Improved due to alloy content |

Typical Applications | General structural use | High-strength structures, PV panel frames |

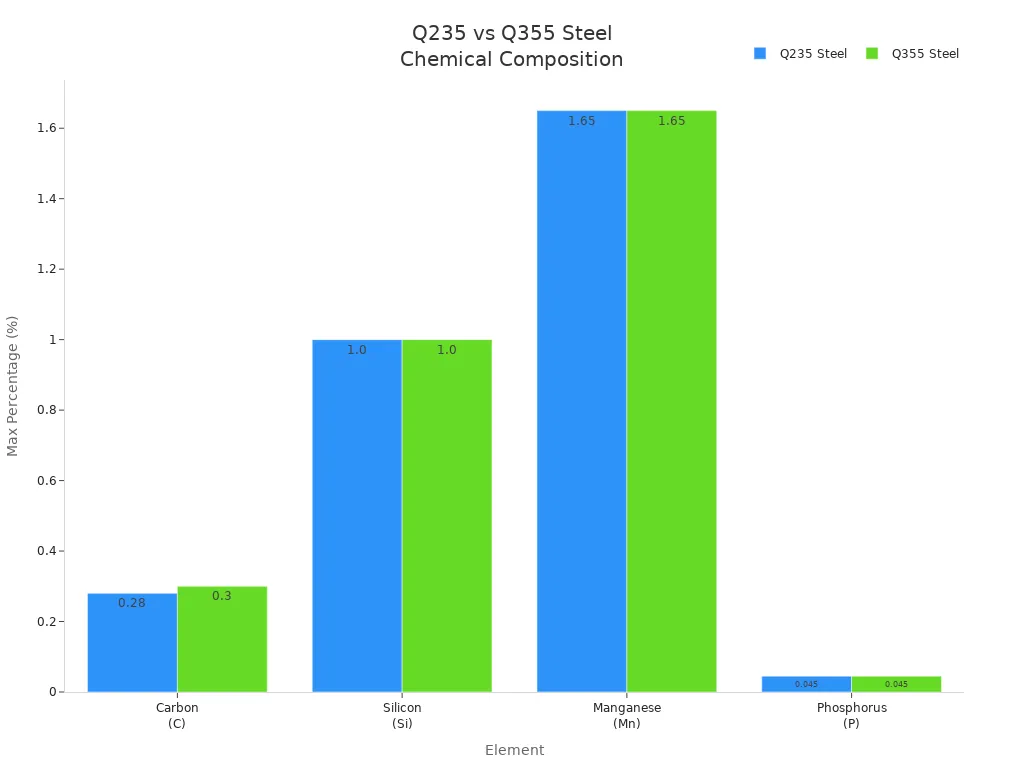

Chemical Composition Table

Element | Q235 Steel (max %) | Q355 Steel (max %) |

|---|---|---|

Carbon (C) | 0.28 | 0.30 |

Silicon (Si) | 1.00 | 1.00 |

Manganese (Mn) | 1.65 | 1.65 |

Phosphorus (P) | 0.045 | 0.045 |

Sulfur (S) | 0.045 | N/A |

You can see that Q355 has slightly more carbon and sometimes more alloying elements. This difference gives Q355 its higher strength and better performance in tough conditions.

Note: Q235’s lower carbon content makes it easier to weld. If you need to do a lot of welding on your Steel Structure for PV Panel, Q235 may save you time and reduce the risk of weld cracks. Q355’s higher carbon content means you must follow stricter welding procedures.

Summary Table

Here is a summary table to help you compare Q235 and Q355 quickly:

Property | Q235 Steel | Q355 Steel |

|---|---|---|

Yield Strength | ~235 MPa | ~345-355 MPa |

Tensile Strength | ~235 MPa | ~450 MPa |

Cost | Lower | Higher (but usually <$100/ton more) |

Corrosion Resistance | Moderate | Needs protection in harsh settings |

Weldability | Excellent | Good, but needs care |

Durability | Good for general use | Better for demanding projects |

Typical Use | Standard structures | High-load, long-term structures |

You should always match your steel choice to your project’s needs. Q355 gives you more strength and durability, but Q235 offers easier welding and lower cost. Both steels work well for PV panel structures when you use the right protective coatings.

Strength Comparison

Yield Strength

When you compare Q235 and Q355, you notice a clear difference in yield strength. Q235 steel has a nominal minimum yield strength of 235 MPa for plates up to 16 mm thick. Q355 steel, on the other hand, offers a minimum yield strength of about 345 MPa. This 100 MPa gap means Q355 can handle much higher stress before it starts to deform. The naming system for these steels reflects their yield strength, so you can quickly identify their performance. Q235’s yield strength drops as the plate gets thicker, while Q355 maintains its strength up to 40 mm thickness. This consistency makes Q355 a strong choice for demanding applications.

Note: Yield strength tells you how much force the steel can take before it bends. Higher yield strength means better resistance to heavy loads and impacts.

Structural Use

You want your Steel Structure for PV Panel to stay stable under all conditions. Q355’s higher yield strength gives you more safety margin, especially in large or high-load installations. Both Q235 and Q355 work well for support beams, flange heads, and ground anchors. However, Q355 stands out in projects where you expect strong winds, heavy snow, or challenging soil.

Q355 steel provides greater load-bearing capacity and stability.

Both steels, when hot-dip galvanized, resist corrosion and last for decades outdoors.

Q355 improves anti-tilt and anti-pullout performance, which helps your structure stay secure in harsh weather.

Simulations and stress tests show that both Q235 and Q355 can meet international standards for wind loads up to 60 m/s and snow loads up to 1.4 kN/m². Engineers often choose Q355 for large-scale solar farms or areas with extreme weather, while Q235 fits smaller or less demanding projects. You can trust both steels to deliver reliable performance, but Q355 gives you extra confidence for critical applications.

Cost Analysis

Material Cost

When you compare Q235 and Q355, you notice a clear difference in price. Q235 steel usually costs less because it contains fewer alloying elements and has lower strength. Q355 steel, with its higher strength and improved durability, comes at a premium. You can see the typical price ranges in the table below:

Steel Grade | Price Range (USD/ton FOB) |

|---|---|

Q235 | $508 - $518 |

Q355 | $554 - $594 |

In most global markets, Q355 costs about $18 to $40 more per ton than Q235. If you have a tight budget or a large project, this price gap can add up quickly. For direct factory sales, the difference may be smaller, around $15 to $30 per ton. You should always check current market prices before making a final decision.

Installation Cost

You can often reduce installation costs by choosing higher strength steel. Q355’s strength-to-weight ratio lets you use lighter profiles without sacrificing safety. This means you need less steel to achieve the same structural performance. Lighter materials make shipping easier and faster. Your installation team can handle and assemble the parts more quickly, which saves on labor costs. You also spend less on transportation because the total weight drops. These savings can help offset the higher material cost of Q355.

High strength-to-weight ratio allows for lighter structures.

Lighter steel profiles reduce shipping and handling costs.

Faster installation saves on labor expenses.

Long-Term Value

You should always consider the long-term value, not just the upfront cost. Q355 steel offers better durability and resists deformation under heavy loads or harsh weather. This means your structure will likely last longer and require fewer repairs. Over time, the extra investment in Q355 can pay off through lower maintenance costs and fewer replacements. If your project needs to last for decades or faces tough conditions, Q355 often delivers better value in the long run. For short-term or budget projects, Q235 remains a solid choice.

💡 Tip: Weigh both the initial investment and the expected service life when choosing your steel. Sometimes, paying a bit more upfront leads to bigger savings over the years.

Durability

Corrosion Resistance

You want your PV panel structure to last for decades, even when exposed to rain, humidity, or industrial dust. Both Q235 and Q355 steels can resist corrosion well when you apply a hot-dip galvanized coating. This zinc layer forms a dense shield that blocks moisture and chemicals from reaching the steel. Q355 contains more alloying elements, which gives it a slight edge in resisting corrosion, especially in harsh or corrosive environments. However, the real difference comes from the quality of the galvanizing process. If you use proper coatings, both steels can stand up to tough weather and industrial conditions.

🛡️ Tip: Always choose hot-dip galvanizing for outdoor steel structures. This process gives the best protection against rust and extends the life of your investment.

Service Life

You can expect a long service life from both Q235 and Q355 when they are galvanized. In coastal or industrial environments, galvanized steel structures made from either grade often last up to 50 years. The zinc coating protects the steel from salty air, rain, and dust. This means you do not need to worry about early failure or frequent replacements. Both Q235 and Q355 perform well in these challenging settings, so you can select either one with confidence if you use proper surface treatments.

Maintenance

You will find that maintenance needs stay low for both Q235 and Q355 when you use a quality galvanized finish. The zinc layer prevents rust, so you only need to inspect the structure once or twice a year. Look for scratches or damage to the coating, and repair any exposed spots quickly. This simple routine helps you avoid costly repairs and keeps your PV panel structure safe and strong. If you install your system in a coastal or industrial area, regular inspections become even more important. By following these steps, you ensure your steel structure remains reliable for decades.

Steel Structure for PV Panel: Application Scenarios

Large Projects

When you work on large-scale solar farms, you need steel that can handle heavy loads and last for decades. Q355 is the top choice for these projects because it offers high strength and excellent durability. You often see Q355 and galvanized steel used for ground screws, posts, rails, and bracing. These materials support strong wind and snow loads, making them reliable for big installations. The table below shows typical steel grades and their uses in large PV projects:

Steel Grade / Alloy | Key Attributes | Typical Use in PV Structures |

|---|---|---|

Q235B Steel | High strength, durable, needs galvanization for corrosion resistance | Large-scale solar farms, strong wind/snow load areas |

Galvanized Steel | Cost-effective, long lifespan, good for various climates | Support structures, ground screws, rails, bracing |

Galvalume Steel | Superior corrosion resistance, sunlight reflection | Harsh environments, thermal performance needed |

POSMAC Steel | Highest corrosion protection, higher cost | Extremely harsh environments |

For large or long-term projects, Q355 and galvanized steel give you the best balance of strength and service life.

Budget Projects

If you manage a project with a tight budget, you want materials that save money but still perform well. Q235 is a practical choice for most budget-focused installations. You also see galvanized steel fasteners and zinc-coated steel rods used because they cost less and provide reasonable corrosion resistance. Steel 1020 is another affordable option for grounding conductors. These materials work well in moderate climates and help you keep costs low.

Choose Q235 or galvanized steel for standard structures.

Use hot-dip galvanized fasteners for better value in moderate environments.

Harsh Environments

When your PV panel structure faces extreme weather or corrosive conditions, you need extra protection. Both Q235 and Q355 perform well when you add hot-dip galvanizing or powder coating. These coatings protect the steel from rust, even in coastal or industrial areas. Q355 offers higher strength and better resistance to deformation, which is important for areas with high winds or seismic activity. You can trust these steels to last over 30 years with the right surface treatment.

Always select steel with proper coatings for harsh environments to ensure long-term durability.

Custom Needs

Every project has unique requirements. You might need special sizes, finishes, or fastener types. Both Q235 and Q355 offer wide customization options. You can choose from different sizes, surface finishes like zinc plating or Dacromet, and even request custom packaging. Design services such as 3D modeling and CAD drawings help you meet specific technical standards. Delivery times can be fast, especially for urgent orders.

Customize size, finish, and design to fit your project.

Select the steel grade based on load, environment, and service life needs.

Your choice between Q235 and Q355 depends on project details like location, load demands, and environmental conditions. Always match your Steel Structure for PV Panel to your project’s technical and durability requirements.

When you select a Steel Structure for PV Panel, always match your steel grade to your project’s needs and environment. Q355 works best for demanding or long-term installations, while Q235 fits most budget projects. Use this checklist to guide your choice:

Check material strength and durability for your load requirements.

Consider corrosion resistance and protective coatings for harsh sites.

Ensure compatibility with your installation and panel type.

Balance cost-effectiveness with long-term value.

Think about environmental impact and adaptability to climate.

Weigh both immediate costs and future maintenance to make the best decision.

FAQ

What is the main difference between Q235 and Q355 steel?

Q355 steel gives you higher strength and better durability than Q235. You get more load-bearing capacity with Q355. Q235 costs less and works well for standard projects.

Can you weld both Q235 and Q355 easily?

You can weld Q235 easily because of its low carbon content. Q355 needs careful welding procedures. You should follow proper guidelines to avoid cracks when welding Q355.

Which steel grade lasts longer outdoors?

Both Q235 and Q355 last a long time if you use hot-dip galvanizing. Q355 offers better durability in harsh environments. You should always use protective coatings for outdoor use.

Does Q355 always cost much more than Q235?

Q355 usually costs $15–$40 more per ton than Q235. You may save on installation and maintenance with Q355. For budget projects, Q235 remains a good choice.

When should you choose Q235 over Q355?

You should choose Q235 for small or budget-focused PV panel projects. Q235 works well in mild climates and standard installations. For heavy loads or harsh sites, Q355 is a better option.

See Also

Steel Versus Aluminum Choices For Outdoor Telecom Cabinets

Best Materials To Use For ESTEL Telecom Cabinets 2025

Essential Structural Design Features Of ESTEL Outdoor Cabinets

Comparing Durability Of Outdoor Communication Cabinets Today

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA