ESTEL's Complete Guide to Telecom Battery Backup Systems Installation

Telecom battery backup systems ensure uninterrupted communication during power outages. Their importance grows as connectivity demands increase, especially in critical locations like data centers and mobile cell sites.

Uninterrupted power is paramount for communication networks. A service disruption caused by power loss can harm the reputation of service providers.

Proper installation and maintenance enhance system efficiency. Regular upkeep prevents costly repairs, extends the system’s lifespan, and minimizes downtime. It ensures smooth operations while reducing energy consumption and operational expenses.

Key Takeaways

Telecom battery backups keep communication working during power outages. Installing them correctly makes them reliable and avoids service problems.

Collect all tools and equipment before starting the setup. You’ll need rectifier modules, circuit breakers, and monitoring systems for better performance.

Follow safety rules and regulations during installation. This keeps workers and equipment safe while making sure the system works well.

Check and maintain battery systems often. Monthly inspections find problems early and help the system last longer.

Use smart monitoring systems to watch battery health. These systems give live updates and warnings to stop failures.

Preparation for Telecom Battery Backup Systems Installation

Essential Tools and Equipment

Before starting the installation, gather the necessary tools and equipment to ensure a smooth process. You will need telecom rectifier modules, DC distribution panels, circuit breakers, and fuses. Battery backup systems are essential, along with monitoring and control systems to track performance. Efficiency features, modularity, and redundancy should also be prioritized to enhance system reliability.

Having the right tools minimizes errors and reduces installation time. For example, using high-quality circuit breakers and fuses prevents electrical faults, while modular components simplify future upgrades. Proper equipment selection ensures the system operates efficiently during outages, safeguarding communication networks.

Safety Measures and Compliance Standards

Adhering to safety standards for telecom battery cabinets is crucial for protecting personnel and equipment. Regulatory compliance ensures installations meet industry benchmarks. Key standards include UL 1973 for stationary battery safety, IEC 62619 for industrial lithium-ion batteries, and NFPA 855 for large-scale energy storage systems.

Standard | Focus Area |

|---|---|

UL 1973 | Stationary battery safety |

IEC 62619 | Industrial lithium-ion batteries |

NFPA 855 | Large-scale energy storage systems |

Follow translated safety warnings and battery safety notices provided by manufacturers. Ensure compliance with FCC safety guidelines and RF exposure limits. These measures reduce risks and maintain system integrity.

Tip: Always verify the manufacturer's declaration of conformity to ensure compliance with regional regulations.

Site Assessment and Planning

A thorough site assessment lays the foundation for a successful installation. Evaluate the location's power requirements and environmental conditions. Perform DC calculations to confirm the battery backup system can handle outages effectively. Consider factors like temperature, humidity, and space constraints to optimize system placement.

Plan the layout to ensure easy access for maintenance and future upgrades. Proper planning prevents operational disruptions and extends the system's lifespan. By addressing these factors early, you create a reliable and efficient setup that supports uninterrupted communication.

Step-by-Step Installation of Telecom Battery Backup Systems

Positioning and Mounting the Battery Backup System

The first step in the installation process involves selecting the right location for your battery backup system. Choose a site that meets environmental requirements, such as stable temperature and low humidity. Ensure the area is free from dust and vibrations, as these factors can affect the system's performance over time.

Position the battery backup system on a sturdy, level surface. Use mounting brackets or racks to secure the system in place. This prevents movement during operation and ensures safety. If you are installing multiple units, maintain adequate spacing between them to allow proper ventilation and easy access for maintenance.

Tip: Always follow the manufacturer's guidelines for mounting to avoid voiding warranties or compromising system stability.

Wiring and Electrical Connections

Proper wiring is critical to the success of the installation process. Begin by verifying that the battery's voltage and capacity match the specifications of your telecom system. Most telecom battery backup systems use 48V battery strings, which typically consist of 24 series-connected cells.

Follow these steps for wiring:

Inspect the battery terminals for any signs of corrosion or damage. Clean them if necessary to ensure a secure connection.

Use appropriately rated cables to connect the battery terminals to the rectifier's designated ports. Tighten the connections to prevent voltage drops.

Measure the voltage at the rectifier's battery input terminals after completing the connections. The reading should match the battery's rated voltage.

Evidence Type | Description |

|---|---|

Technical Standards Workshop | Focused on the need for standards in battery types, maintenance, and technologies. |

AT&T Warranty Information | Highlights the importance of proper installation to avoid warranty issues. |

Customer Education | Emphasizes informing users about battery limitations during power outages. |

Ensure all wiring complies with technical standards to maintain system reliability and safety. Avoid over-tightening connections, as this can damage the terminals.

Securing the System and Final Checks

Once the wiring is complete, secure the battery backup system to prevent accidental disconnections or damage. Double-check all connections to ensure they are tight and properly aligned. Inspect the system for any loose components or exposed wires.

Perform a final round of testing to validate the installation process. Check the system's performance under load conditions to confirm it can handle the expected power demands. Monitor the voltage and current levels to ensure they remain within the specified range.

Note: Document the results of your tests for future reference. This helps in troubleshooting and maintenance.

By following these steps, you can complete the installation process efficiently and ensure your telecom battery backup systems operate reliably during power outages.

Testing and Validation of Battery Backup System

Performance Testing and Monitoring

Testing ensures the reliability of telecom battery backup systems under various conditions. You should conduct environmental tests to evaluate performance in extreme temperatures, humidity, and altitude. Abuse testing simulates physical damage, overcharging, and short circuits to verify system resilience. Life-cycle testing assesses long-term durability, while charge-discharge cycles measure efficiency during regular operations.

Testing Method | Purpose |

|---|---|

Environmental Testing | Evaluates performance in extreme temperatures, humidity, and altitude. |

Abuse Testing | Simulates physical damage, overcharging, and short circuits. |

Life-Cycle Testing | Assesses long-term durability and reliability under operational conditions. |

Charge-discharge or micro-cycles | Tests the battery's performance during regular charging and discharging cycles. |

Safety Components | Includes tests for interlock, shut down signals, etc. |

Smart monitoring systems, such as those offered by Alpine Power Systems, provide early warnings of battery issues. These systems conduct proactive resistance tests to ensure telecom battery cabinets perform optimally. Manufacturers like Servato and Alber also offer advanced monitoring tools to document performance data effectively.

Tip: Periodic testing of backup power systems helps identify potential issues before they escalate, ensuring uninterrupted communication during outages.

Troubleshooting Installation Issues

Installation issues can compromise the functionality of your battery backup system. Common problems include loose connections, incorrect wiring, and mismatched voltage levels. Begin troubleshooting by inspecting all electrical connections for tightness and alignment. Verify that the battery voltage matches the system's specifications.

Use smart monitoring systems to detect faults like short circuits or overcharging. These systems can report issues in real-time, allowing you to address them promptly. If the problem persists, consult the manufacturer's guidelines or seek professional assistance.

Note: Document all troubleshooting steps to streamline future maintenance and repairs.

Ensuring System Efficiency and Reliability

Efficiency and reliability are critical for telecom battery cabinets. Regular monitoring of voltage, current, and temperature ensures the system operates within safe limits. Cell balancing tests prevent overcharging or discharging, while insulation resistance tests verify adequate system insulation.

Evidence Description | Key Points |

|---|---|

Discusses requirements for backup power solutions and consumer responsibilities. | |

Monitoring Responsibilities | Comments support monitoring of backup power status to ensure performance. |

Variety of Technologies | Providers use various backup power technologies, reflecting flexibility in solutions. |

Integrating smart monitoring systems enhances reliability by providing real-time data on system performance. These systems help you identify inefficiencies and optimize operations. Scheduling periodic maintenance further ensures the longevity of your telecom battery backup systems.

Tip: Always prioritize preventive measures to avoid costly repairs and downtime.

Integration with Telecom Systems

Connecting to Rectifiers and Power Distribution Units

To ensure seamless operation, you must connect the battery backup system to rectifiers and power distribution units (PDUs). Rectifiers convert AC power to DC, which is essential for charging the batteries and powering telecom equipment. Begin by identifying the input and output terminals on the rectifier and PDU. Use appropriately rated cables to establish secure connections.

When connecting the system, verify that the voltage and current ratings align with the specifications of your telecom battery cabinets. This step prevents overloading and ensures efficient power flow. Battery Management Systems (BMS) play a crucial role here. They enhance safety by providing real-time data on voltage, current, and temperature. Advanced BMS technologies, such as those incorporating AI and IoT, improve operational efficiency and enable predictive maintenance.

Tip: Always double-check the polarity of connections to avoid damaging the equipment.

Synchronizing with Communication Equipment

Proper synchronization between the battery backup system and communication equipment is vital for uninterrupted service. Start by configuring the system to match the power requirements of your telecom devices. Most telecom battery cabinets operate at 48V, which is compatible with standard communication equipment.

Use monitoring tools to ensure the system responds effectively to load changes. Intelligent interfacing units, equipped with advanced controllers, regulate voltage precisely. This ensures reliable operation even during fluctuating power demands. By synchronizing the system correctly, you can minimize downtime and maintain consistent network performance.

Note: Regularly test the synchronization process to identify and resolve potential issues early.

Optimizing Compatibility with Existing Systems

To optimize compatibility, you must evaluate the types of telecom battery cabinets in use and their integration with existing infrastructure. Modern systems, such as those incorporating Proton Exchange Membrane Fuel Cells (PEMFCs), offer enhanced reliability and cost-effectiveness. These systems reduce the need for large battery banks, making them ideal for space-constrained setups.

Intelligent interfacing units further improve compatibility by using genetic algorithm-assisted controllers for precise voltage regulation. This technology ensures smooth operation despite load variations. Additionally, the system’s monitoring capabilities allow for early detection of issues, enabling proactive maintenance and reducing downtime.

When you choose the right battery cabinet, consider key features of telecom battery cabinets, such as modularity, scalability, and environmental resilience. These features ensure the system integrates seamlessly with your existing setup, supporting long-term operational efficiency.

Tip: Conduct regular compatibility assessments to keep your system updated with the latest technologies.

Maintenance Tips for Telecom Battery Cabinets

Regular Inspection and Cleaning Practices

Regular maintenance checks are essential for ensuring the reliability of telecom battery cabinets. Monthly inspections help you identify issues like corrosion, loose connections, or dirt accumulation that can compromise performance. Cleaning the battery terminals prevents electrical faults and enhances safety.

Maintenance Practice | Impact on Performance |

|---|---|

Monthly inspections | Prevents corrosion and electrical faults |

Cleaning of terminals | Enhances battery reliability and safety |

Monitoring temperature and humidity | Maintains optimal operating conditions |

Periodic testing of backup systems | Confirms readiness during emergencies |

Documentation of inspection results | Tracks system performance over time |

During inspections, pay attention to temperature and humidity levels. These factors directly affect battery performance and lifespan. Use a soft cloth and non-corrosive cleaning agents to clean terminals. Avoid using water or abrasive materials, as they can damage the components.

Tip: Document inspection results to track system performance over time. This practice helps you identify trends and plan upgrades effectively.

Monitoring Battery Health and Performance

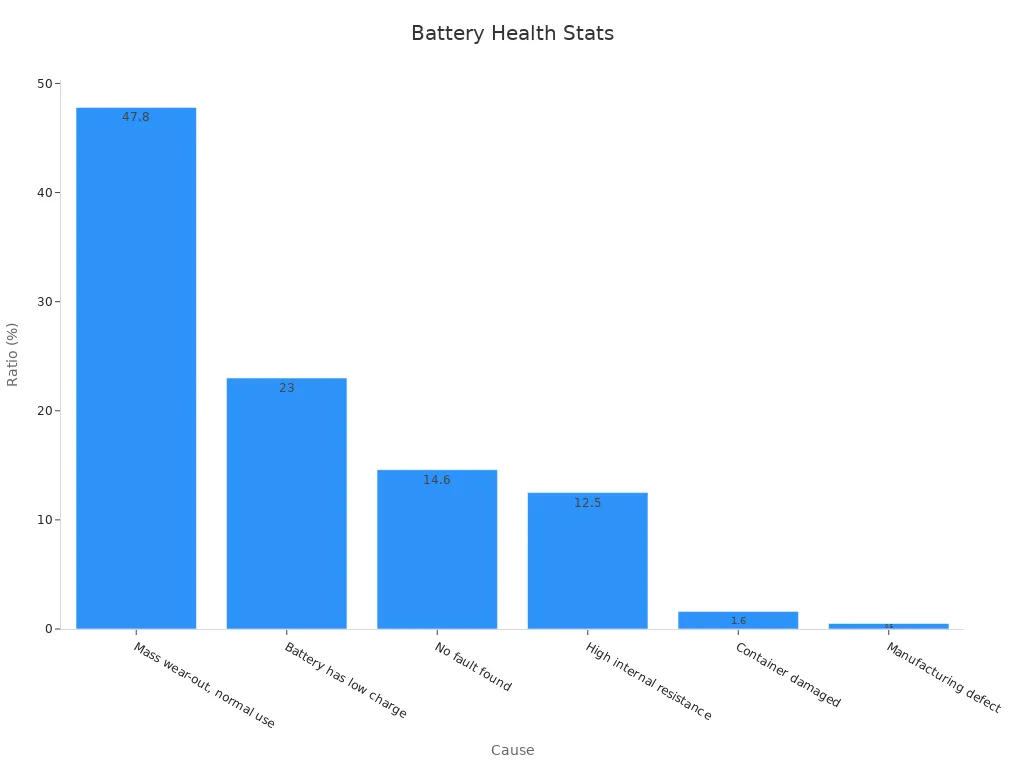

Monitoring the health of telecom battery cabinets ensures they operate efficiently during emergencies. Key metrics like voltage, charge current, and resistance provide valuable insights into battery performance. High internal resistance often signals a failing battery, while low charge levels can reduce reliability.

Cause | Ratio |

|---|---|

Mass wear-out, normal use | 47.8% |

Battery has low charge | 23% |

No fault found | 14.6% |

High internal resistance | 12.5% |

Container damaged | 1.6% |

Manufacturing defect | 0.5% |

Smart monitoring systems simplify this process by providing real-time data on battery conditions. These systems alert you to potential issues like overcharging or overheating, allowing you to address them promptly. Batteries in warmer climates often have shorter lifespans, so monitoring temperature is especially important in such regions.

Note: Regular monitoring improves average battery life, which has increased from 41 months in 2000 to 50 months in 2005 due to better maintenance practices.

Scheduling Preventive Maintenance and Professional Servicing

Preventive maintenance extends the lifespan of telecom battery cabinets and reduces the risk of costly outages. Schedule monthly inspections to check ambient temperature, voltage, and charge current. These metrics help you identify potential issues early and maintain optimal performance.

Key Metric | Importance |

|---|---|

Ambient Temperature | Affects battery performance and lifespan |

Charge Current | Indicates battery charging efficiency |

Voltage | Essential for assessing battery health |

Resistance | High resistance can signal a failing battery |

Data logging and trend analysis provide insights into battery health and replacement timelines. Professional servicing ensures critical power supplies, such as UPS and DC power systems, remain reliable. Technicians can perform advanced tests, like insulation resistance checks, to verify system integrity.

Tip: Preventive maintenance not only enhances reliability but also reduces operational expenses by avoiding emergency repairs.

Proper installation and maintenance of telecom battery backup systems ensure uninterrupted communication and reduce operational risks. Following systematic maintenance practices minimizes service disruptions and enhances reliability.

A telecom provider reduced service complaints by addressing outdated quality control systems.

Another company improved customer satisfaction by identifying root causes of quality issues.

Risk of Losing Service (%) | |

|---|---|

4 hours | 6.8 |

8 hours | 3.9 |

15-20 hours | 2.0 |

Documenting maintenance tasks helps track performance and supports continuous improvement. Trust ESTEL for dependable telecom power solutions that prioritize efficiency and reliability.

FAQ

1. What is the ideal location for installing a telecom battery backup system?

Choose a clean, dry area with stable temperature and low humidity. Avoid locations with excessive dust or vibrations. Ensure the space allows proper ventilation and easy access for maintenance.

Tip: Position the system on a sturdy, level surface to prevent movement during operation.

2. How often should you inspect telecom battery cabinets?

Perform monthly inspections to check for corrosion, loose connections, and dirt accumulation. Regular checks help maintain optimal performance and extend the system's lifespan.

Note: Document inspection results to track trends and plan upgrades effectively.

3. Can you use any type of battery for telecom systems?

No, you must use batteries designed for telecom applications. Most systems use 48V battery strings with series-connected cells. Ensure compatibility with your equipment and environmental conditions.

Tip: Consult the manufacturer's guidelines for recommended battery types.

4. What tools are essential for installation?

You need rectifier modules, DC distribution panels, circuit breakers, fuses, and monitoring systems. Use high-quality cables and connectors to ensure reliable electrical connections.

Tool | Purpose |

|---|---|

Rectifier Modules | Converts AC to DC power |

Circuit Breakers | Prevents electrical faults |

Monitoring Systems | Tracks performance and health |

5. How can you monitor battery health effectively?

Use smart monitoring systems to track voltage, current, and temperature. These systems provide real-time alerts for issues like overcharging or overheating.

Emoji Reminder: 🔋 Regular monitoring improves battery lifespan and ensures uninterrupted communication during outages.

See Also

In-Depth Risk Assessment Guide for Telecom Cabinet Batteries

Calculating Power Systems and Battery Needs for Telecom Cabinets

Essential Energy Storage Solutions for ESTEL Telecom Cabinets

Integrated Photovoltaic Inverter and Battery Systems for Telecom Cabinets

Photovoltaic Energy Storage Solutions for Telecom Cabinet Power

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA