Aging Detection of Telecom Cabinet Lead-Acid Batteries: Internal Resistance Analysis of Plate Sulfation & Lifespan Prediction

Telecom cabinet battery health depends on accurate detection of aging signs like increased internal resistance and plate sulfation. Internal resistance analysis offers clear insights into battery performance:

Description | |

|---|---|

Energy Loss | Higher internal resistance leads to more energy loss and shorter standby times. |

State-of-Charge Errors | Increased resistance causes errors in state-of-charge estimation, lowering reliability. |

Charge-Discharge Efficiency | Lower charge-discharge efficiency results from rising resistance, reducing system performance. |

Operators rely on these assessments to maintain reliable service. Plate sulfation, temperature shifts, and regular maintenance also influence battery lifespan. Predictive maintenance and lifespan estimation help prevent unexpected failures and support efficient telecom operations.

Key Takeaways

Monitor internal resistance regularly to detect aging signs in lead-acid batteries. Early detection helps prevent unexpected failures.

Implement proper charging practices to extend battery life. Ensure full charges and avoid overcharging to minimize sulfation.

Conduct routine maintenance checks every three to six months. Regular inspections can identify issues before they disrupt service.

Utilize predictive maintenance strategies to reduce downtime and maintenance costs. Data analytics can optimize battery replacement cycles.

Understand environmental impacts on battery lifespan. High temperatures can accelerate aging, while cold conditions can increase internal resistance.

Importance of Telecom Cabinet Battery Health

Operational Risks

Telecom networks depend on reliable backup power. A healthy telecom cabinet battery ensures that critical systems remain online during outages. When batteries age or fail, several operational disruptions can occur. The table below highlights common issues:

Disruption Type | Description |

|---|---|

Battery Overheating | Excessive heat can reduce battery lifespan and create safety hazards. |

Voltage Imbalances | Different voltage levels can lead to premature battery failure and downtime. |

Corrosion on Terminals | Accumulation of moisture or debris can create resistance, reducing power transfer efficiency. |

Reduced Battery Capacity | Aging batteries or improper charging can lead to inadequate backup power. |

Faulty Connections or Loose Wiring | Improper installation or wear can cause intermittent power supply and system failures. |

A telecom cabinet battery in poor condition increases the risk of these disruptions. Operators may face unexpected downtime, which can interrupt service for customers and damage network equipment. Facilities that maintain healthy batteries experience fewer emergencies and maintain higher system uptime.

Cost and Reliability

Battery health directly affects both the reliability and financial stability of telecom operations. Poor battery performance leads to several negative outcomes:

Poor battery health leads to unplanned downtime, which can cost telecom networks thousands in SLA penalties and lost customers.

33% of downtime in telecom networks is attributed to power outages, emphasizing the critical role of battery performance in maintaining uptime.

Facilities with backup power configurations can achieve a 25% increase in operational reliability.

Financial consequences from unexpected telecom cabinet battery failures can be severe. The table below outlines potential costs:

Risk | Potential Cost |

|---|---|

Equipment failure due to power surge | $5,000 – $30,000 per incident |

Service downtime (SLA penalties & lost revenue) | $1,000 – $100,000+ depending on scope |

Technician dispatch for repair | $500 – $3,000 per visit |

Replacing damaged batteries | $1,000 – $10,000 |

Legal/contractual damages | Varies significantly |

Reputation damage | Hard to quantify, but often severe |

A well-maintained telecom cabinet battery reduces these risks. Regular monitoring and timely replacement help operators avoid costly repairs and maintain customer trust.

Lead-Acid Battery Aging Factors

Internal Resistance

Internal resistance plays a major role in the aging process of lead-acid batteries. As batteries age, their internal resistance increases. This rise happens because the active materials inside the battery degrade over time. The buildup of lead sulfate on the plates also contributes to higher resistance.

Corrosion of metal current carriers, especially in the plates, reduces their cross-section and increases resistance.

Changes in the porosity, crystal structure, and chemical composition of electrodes further raise resistance.

A higher internal resistance means the battery loses more energy during operation. This loss leads to shorter backup times and less efficient performance for telecom cabinet battery systems.

Plate Sulfation

Plate sulfation is a common cause of reduced battery performance. Sulfation occurs when lead sulfate crystals form on the battery plates. This usually happens if the battery does not receive a full charge. Over time, these crystals harden and become difficult to remove.

Longer charging times

Excessive heat build-up

Shorter running times between charges

Dramatically shorter battery life

Complete battery failure

Sulfation blocks the chemical-to-electrical conversion inside the battery. As a result, the telecom cabinet battery may show reduced runtime, increased charging times, and eventual failure.

Environmental Conditions

Environmental factors greatly affect the aging rate of lead-acid batteries. High temperatures speed up chemical reactions, causing plate corrosion and lowering electrolyte levels. For every 10°C increase, battery lifespan can be cut in half. For example, a battery designed for five years at 25°C may last only two to three years at 30°C.

Cold temperatures increase internal resistance, which reduces charge acceptance and capacity. Freezing conditions can crystallize the electrolyte, leading to permanent damage and possible battery failure.

Humidity also plays a role by promoting corrosion and water loss, which further shortens battery life.

Note: The main factors contributing to lead-acid battery aging include sulfation, corrosion, water loss, electrolyte stratification, and positive plate grid corrosion and growth.

Internal Resistance Measurement

Measurement Tools

Selecting the right tool for measuring internal resistance ensures accurate results and reliable battery health assessment. Different tools offer varying levels of precision and functionality. The table below summarizes the most common options:

Tool Type | Description |

|---|---|

Multimeters | Versatile tools that can measure voltage, current, and resistance; suitable for quick checks. |

Battery Testers | Specialized devices designed for accurate internal resistance measurement of batteries. |

Impedance Analyzers | High-precision devices measuring real and imaginary components of internal resistance. |

Integrated Diagnostic Systems | Advanced systems with built-in capabilities for comprehensive battery health diagnostics. |

Battery testers and impedance analyzers provide the most reliable results for telecom applications. Integrated diagnostic systems often combine several functions, making them ideal for large-scale monitoring.

Several methods exist for measuring internal resistance. Each method has unique advantages and limitations:

Method | Description | Accuracy/Applicability |

|---|---|---|

Density method | Estimates internal resistance by measuring electrolyte density. | Narrow application; not suitable for sealed batteries. |

Open circuit voltage method | Measures terminal voltage to estimate internal resistance. | Very poor accuracy; can lead to incorrect conclusions. |

DC discharge method | Measures voltage drop during high current discharge to calculate resistance. | Must be done offline; can damage battery and affect capacity/life. |

AC injection method | Injects AC current to measure voltage response and phase difference. | Allows online detection; complex and affected by interference factors. |

Internal resistance tester | Uses advanced AC discharge test for accurate measurement. | Can assess battery capacity and technical status; suitable for group or single measurement. |

For telecom cabinet battery maintenance, internal resistance testers and impedance analyzers are preferred due to their accuracy and safety.

Testing Procedure

A consistent testing procedure helps technicians track battery health over time. Regular measurements allow early detection of aging or faults. The following steps outline the standard process for testing internal resistance in lead-acid batteries:

Ensure all battery connections are clean, tight, and free of corrosion.

Equalize charge the batteries for 12 hours at a voltage of 14.1V per block at 25℃.

Disconnect the charger and let the battery rest for 1 hour.

Measure and record the voltage of each battery block using a voltmeter.

Use an internal resistance tester to measure each battery block's resistance, ensuring direct contact with the terminals.

Repeat the resistance measurement three times and calculate the average.

📅 Tip: Establish a baseline measurement immediately after installation. Schedule follow-up tests every 3 to 6 months. For critical sites, perform at least one test annually to ensure ongoing reliability.

Safety Tips

Safety remains a top priority during internal resistance testing. Lead-acid batteries store significant energy and contain hazardous materials. Technicians should follow these precautions:

Wear insulating gloves to avoid short circuits or electrolyte contact.

Ensure the battery surface is dry and free from leakage.

Do not test damaged, leaking, or bulging batteries. These may short circuit or explode.

Avoid touching probes to metals other than the positive and negative terminals, such as battery holders, during testing.

⚠️ Note: Always inspect the battery before testing. Replace any unit that shows signs of damage or leakage to prevent accidents.

A careful approach to measurement and safety ensures accurate results and protects both personnel and equipment during telecom cabinet battery maintenance.

Sulfation Analysis

Signs of Sulfation

Sulfation often develops quietly inside a lead-acid battery. Early signs can help technicians spot problems before they become severe. A battery with sulfation may show longer charging times. The voltage may rise quickly during charging, but the battery fails to hold a charge. Users might notice reduced backup time or frequent need for recharging. Sometimes, the battery case feels warmer than usual during operation. In severe cases, white or grayish deposits appear on the plates when inspected. These symptoms signal that the chemical reactions inside the battery have slowed down. The battery cannot deliver the expected power, which puts the telecom cabinet battery at risk of failure during outages.

⚠️ Tip: Regularly check for these warning signs to prevent unexpected battery failures.

Detection Methods

Technicians use several methods to detect sulfation in lead-acid batteries. Some approaches provide real-time data, while others focus on improving battery life and reducing sulfation risk. Common detection and prevention techniques include:

Real-time monitoring with cell voltage and pressure sensors helps identify abnormal patterns linked to sulfation.

Pulsed charging can extend battery cycle life and minimize the buildup of sulfate crystals.

High finishing currents and current-interrupt charging algorithms reduce sulfation and limit unwanted gassing.

Nondestructive and low-cost diagnostic tools support battery management systems by identifying sulfation without damaging the battery.

These methods allow operators to maintain battery health and avoid costly downtime. Early detection and intervention keep backup systems reliable and efficient.

Telecom Cabinet Battery Maintenance

Regular Testing

Technicians perform regular testing to maintain battery reliability. They check voltage, internal resistance, and physical condition. These checks help identify problems before they cause failures.

Reliability assurance results from routine inspections. Batteries provide backup power during emergencies, supporting uninterrupted communication services.

Risk mitigation occurs when technicians find and fix issues early. This reduces unexpected failures and downtime, protecting customers.

Optimized maintenance comes from data collected during tests. Teams schedule repairs and replacements based on actual battery conditions, saving time and resources.

🔍 Tip: Schedule battery tests every three to six months. Record all results for future reference.

Charging Practices

Proper charging practices extend battery life and minimize sulfation. Technicians follow several steps to keep batteries healthy:

They ensure full charges after each use. This prevents sulfate build-up on the plates.

They control temperature during charging and storage. Batteries perform best below 75°F, which reduces self-discharge and sulfation.

They monitor voltage levels. Keeping voltage above 12.4 volts helps prevent sulfation.

They avoid overcharging. Excessive charging causes heat and damages the battery, leading to sulfation.

⚡ Note: Use smart chargers with automatic shutoff features to prevent overcharging.

Electrolyte Checks

Electrolyte levels affect battery performance. Technicians inspect electrolyte regularly to ensure proper function. They look for signs of low fluid, discoloration, or contamination. If levels drop, they add distilled water to restore balance.

A clear electrolyte indicates healthy chemical reactions. Cloudy or dark fluid signals possible damage or contamination.

Technicians also check for leaks around the battery case. Leaks can cause corrosion and reduce battery life.

🧪 Alert: Never use tap water to refill batteries. Minerals in tap water can damage internal components.

Lifespan Prediction Methods

Data Curve Fitting

Engineers use data curve fitting to estimate the remaining useful life (RUL) of lead-acid batteries. This method relies on historical performance data, such as voltage, current, and temperature readings collected over time. By plotting these data points, they can identify trends that signal battery aging. Linear regression and other statistical models help create predictive curves that estimate when a battery will reach the end of its service life.

Historical data plays a crucial role in this process. It reveals how system stress and performance decay over time. Patterns and trends in the data inform predictive models, making lifespan forecasts more accurate. Accurate RUL predictions allow for better maintenance scheduling and asset management. Load cycle data, which records the frequency and intensity of charge-discharge cycles, is especially important. By analyzing these cycles, engineers can predict when a battery is likely to fail.

Several statistical models are commonly used for lifespan prediction in telecom applications. The table below summarizes these models and their characteristics:

Model Type | Description |

|---|---|

Classical Battery Aging Models | Used for general predictions but may not be accurate for all conditions. |

Advanced Weighted Ah-Throughput | Necessary for accurate lifetime estimation of OPzS lead-acid batteries. |

Regression Analysis | Estimates RUL based on battery parameters like voltage, current, and temperature. |

Rain Flow Method | Counts cycles in battery usage to assess aging. |

Bayesian Classifiers | Assesses the state of health using probabilistic approaches. |

Discharge Curve Analysis | Analyzes discharge characteristics to determine battery age. |

📊 Tip: Regression analysis and advanced weighted Ah-throughput models provide the most reliable predictions for telecom battery applications.

Key Predictive Factors

Several factors influence the accuracy of lifespan predictions for lead-acid batteries. Engineers must consider these variables when building predictive models:

Elevated temperatures can double or triple the rate of capacity loss.

Cold temperatures may cause a 30-40% reduction in capacity at 0°F (-18°C).

Batteries designed for a wide operating temperature range perform better in extreme conditions.

Load, temperature, and discharge cycles directly impact battery lifespan. Statistical equations model these effects by accounting for degradation mechanisms.

The number of charge-discharge cycles and the ambient temperature during cycling are key variables in cycling degradation equations.

Regular inspections for wear, such as corrosion or swelling, are essential for maintaining performance.

Cleaning terminals with a non-corrosive solution helps prevent resistance buildup.

Predictive maintenance strategies reduce failure rates and lower costs.

The typical lifespan of lead-acid batteries in telecom applications ranges from 3 to 5 years. Monitoring battery performance regularly ensures optimal functioning.

🔍 Note: Monitoring load, temperature, and discharge cycles provides the data needed for accurate lifespan predictions. These factors help engineers anticipate failures and schedule timely replacements.

The telecom cabinet battery relies on these predictive methods to maintain reliability and reduce unexpected downtime. By combining historical data with advanced modeling techniques, operators can extend battery life and optimize maintenance practices.

Result Interpretation

Key Indicators

Technicians rely on several key indicators to interpret internal resistance and sulfation analysis results in telecom cabinet batteries. These indicators help them understand battery health and predict future performance.

A noticeable increase in internal resistance often signals changes inside a battery cell. This rise can point to aging or damage.

Cells with low capacity usually show higher resistance. However, predicting exact capacity loss remains difficult because different problems can cause similar resistance changes.

Technicians may see scattered data when comparing resistance and capacity. This scatter happens because multiple degradation processes affect the battery at once.

The following table summarizes how certain factors influence internal resistance:

Factor | Key Finding |

|---|---|

State-of-Charge | Resistance peaks when the battery is empty. It is lowest at 80–90% state-of-charge. |

Temperature | Low temperatures cause a significant increase in resistance. |

Aging | Resistance rises as the battery experiences more charge-discharge cycles. |

🔎 Tip: Regularly tracking these indicators helps technicians spot early signs of battery aging and plan maintenance before failures occur.

Replacement Criteria

Operators use specific criteria to decide when to replace telecom cabinet lead-acid batteries. Internal resistance and sulfation levels play a central role in this decision.

A steady increase in internal resistance often means the battery can no longer deliver reliable power.

Sulfation, which forms when batteries do not receive full charges, leads to reduced capacity and further increases resistance.

Monitoring both internal resistance and sulfation allows technicians to judge when a battery’s performance drops below safe limits.

When these parameters reach critical thresholds, replacement becomes necessary to maintain telecom reliability. Timely battery replacement prevents unexpected outages and protects network equipment.

⚠️ Alert: Operators should never ignore rising internal resistance or visible sulfation. Prompt action ensures continuous service and reduces long-term costs.

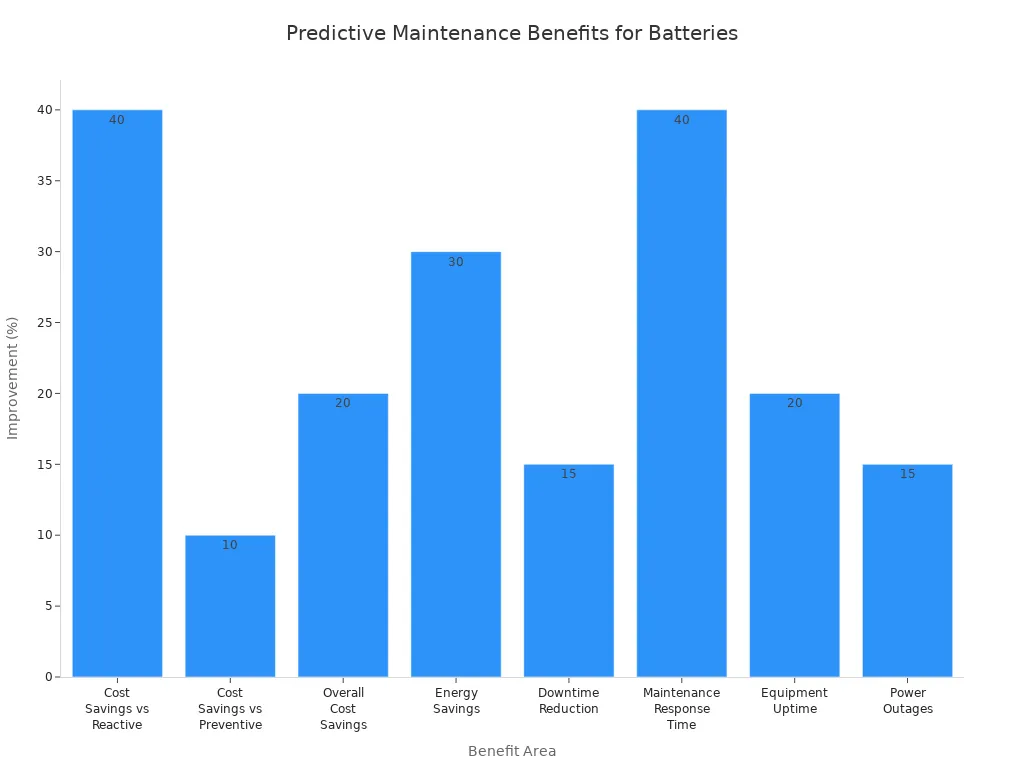

Proactive analysis of internal resistance and sulfation empowers telecom operators to extend battery lifespan and reduce downtime. Predictive maintenance delivers measurable benefits:

Benefit Area | Documented Impact |

|---|---|

Maintenance Cost | |

Downtime | 15% decrease |

Equipment Uptime | 20% improvement |

Power Outages | 15% reduction |

Regular monitoring, data analytics, and AI-driven predictions help operators identify risks early and optimize replacement cycles. Adopting these best practices ensures reliable service and long-term cost savings.

FAQ

What causes internal resistance to increase in lead-acid batteries?

Internal resistance rises as battery plates corrode and active materials degrade. Sulfation and poor maintenance also contribute. High resistance reduces battery efficiency and shortens backup time.

How can technicians detect early signs of sulfation?

Technicians notice longer charging times, reduced backup duration, and higher operating temperatures. Visual inspection may reveal white or gray deposits on battery plates.

Why is regular internal resistance testing important?

Regular testing helps technicians track battery health. Early detection of rising resistance allows timely maintenance or replacement, which prevents unexpected failures and service interruptions.

What environmental factors most affect battery lifespan?

High temperatures accelerate chemical reactions, causing faster aging. Cold temperatures increase resistance and reduce capacity. Humidity promotes corrosion and water loss.

When should operators replace telecom cabinet batteries?

Operators should replace batteries when internal resistance rises steadily or visible sulfation appears. Replacement ensures reliable backup power and protects network equipment.

See Also

A Complete Overview of Telecom Cabinet Battery Risk Assessment

Exploring the Pros and Cons of Lead-Acid Batteries

The Superiority of Lithium Batteries Over Other Options

Calculating Power Systems and Batteries for Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA