Old Telecom Cabinet Upgrades: Compatibility Testing & Cost Analysis of Upgrading Traditional Power Controllers to CANopen

Upgrading a legacy Telecom Cabinet Power Controller to CANopen presents a practical path for modernizing network infrastructure. CANopen offers streamlined integration and reduces operational costs for service providers. Decision-makers must prioritize compatibility testing and cost analysis before any upgrade. They should assess the current hardware, document system requirements, and consult technical documentation. These steps help ensure a smooth transition and maximize return on investment.

Key Takeaways

Upgrading to CANopen simplifies integration and reduces hardware and maintenance costs for telecom cabinets.

Testing compatibility involves checking controller types, protocols, baud rates, and using diagnostic tools to ensure smooth communication.

CANopen upgrades often reuse existing wiring and use modular hardware, lowering installation time and expenses.

Planning upgrades carefully, including technical readiness and financial review, helps avoid risks and ensures a smooth transition.

CANopen’s user-friendly configuration and strong diagnostics reduce training needs and support proactive maintenance.

Compatibility Testing

Telecom Cabinet Power Controller Types

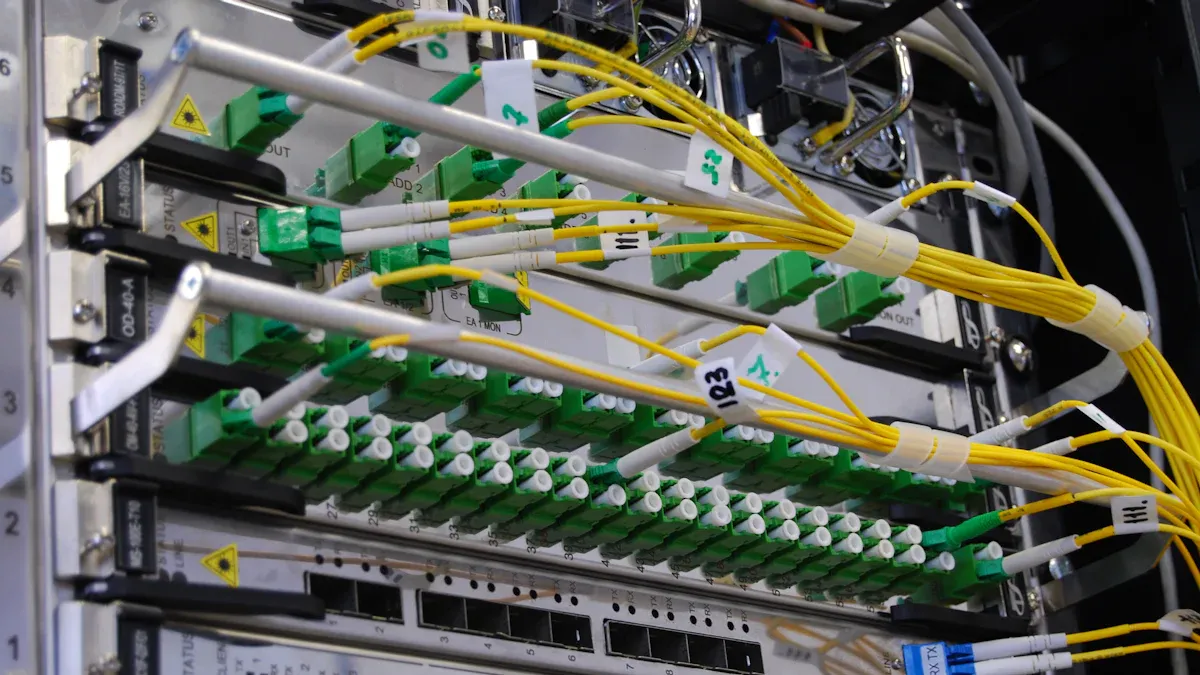

Telecom cabinet power controllers come in several forms. Some use legacy serial protocols, while others rely on proprietary communication standards. Older models often support only basic monitoring and control functions. Newer units may offer modular designs or limited fieldbus support. Each type presents unique challenges when integrating with CANopen. Identifying the specific controller type helps determine the best upgrade path.

Key Compatibility Criteria

Successful CANopen integration depends on meeting several technical criteria. The following table outlines the most important aspects to consider:

Compatibility Aspect | Details |

|---|---|

Protocol Support | CANopen Master and Slave modes; EtherNet/IP Adapter/Slave mode |

CANopen Standards | PDO, DS301 4.0.2, DSP302, EMCY, LSS, NMT, CMT, SYNC, Heartbeat, Node guarding |

Baud Rate | 20 kbit/s to 1000 kbit/s |

Data Size | Up to 510 bytes input and output for CANopen; ~509 bytes input and 505 bytes output for EtherNet/IP |

Number of Slaves Supported | Up to 126 |

Certifications | CE, UL (including hazardous location), ATEX, EMC (multiple EN standards), RoHS |

Physical Installation | DIN-rail mounting (EN 50022), IP20 protection class |

Electrical Requirements | 24V DC input voltage (-10% to +10%), 100mA nominal current, reverse polarity and short circuit protection, isolation provided |

Configuration | Easy configuration via Anybus Configuration Manager software; no programming required |

Additional Features | Slim design, no PLC card slot needed, fast cyclic I/O data transfer, life cycle management |

Controllers must support CANopen Master or Slave modes. They should comply with DS301 and related standards. The hardware must match required baud rates and data sizes. Proper certifications and physical installation options ensure safety and reliability.

Testing Steps

Engineers should follow a structured process to verify compatibility:

Inventory Existing Devices

List all telecom cabinet power controller models and their communication interfaces.Review Technical Documentation

Check manuals for protocol support, baud rates, and configuration options.Set Up a Test Environment

Connect a CANopen master to the controller using a test bench.Verify Communication

Use CANopen’s Write-to-node function to send and receive data. Confirm that the controller responds correctly.Check Configuration and Control

Adjust parameters and monitor outputs. Ensure that all control functions operate as expected.Monitor for Errors

Observe for communication faults, data mismatches, or unsupported features.

Tip: Use diagnostic tools to capture CANopen traffic and identify issues early in the process.

Common Issues & Solutions

Several challenges may arise during compatibility testing:

Unsupported Protocols

Some telecom cabinet power controllers may not natively support CANopen. Engineers can use protocol converters or interface modules to bridge the gap.Baud Rate Mismatches

If the controller and CANopen network operate at different speeds, adjust settings or use compatible hardware.Configuration Difficulties

Complex parameter settings can slow down integration. Configuration software like Anybus Configuration Manager simplifies this process.Electrical Incompatibility

Voltage or current mismatches may cause failures. Verify all electrical requirements before connecting devices.Communication Errors

Issues such as node guarding or heartbeat failures often result from incorrect network settings. Double-check all CANopen parameters and retry the test.

Note: Early identification of these issues reduces project delays and helps ensure a smooth upgrade.

Cost Analysis

Hardware Costs

Upgrading to CANopen often reduces hardware expenses. CANopen controllers require fewer specialized components than legacy systems. Many modern CANopen modules feature compact designs and support DIN-rail mounting, which simplifies installation. Service providers can often reuse existing cabinet wiring and power supplies, further lowering costs.

A typical cost breakdown for hardware includes:

CANopen controller modules

Interface converters (if needed)

Cables and connectors

Power supplies (if upgrades are necessary)

Hardware Component | Legacy System Cost | CANopen System Cost |

|---|---|---|

Controller Module | High | Moderate |

Interface Converter | Sometimes Needed | Rarely Needed |

Wiring & Connectors | Standard | Standard |

Power Supply | May Require Upgrade | Often Reusable |

Note: CANopen’s modular approach allows for incremental upgrades, which helps organizations spread costs over time.

Installation & Software

Installation costs depend on the complexity of the existing telecom cabinet. CANopen’s plug-and-play features reduce installation time. Most CANopen controllers use configuration software that does not require programming skills. This feature lowers the learning curve for technicians.

Key installation and software cost factors include:

Labor for removing old controllers and installing new ones

Time spent configuring CANopen nodes

Licensing fees for configuration software (if applicable)

Training for staff on new systems

Many vendors bundle configuration tools with their hardware. This practice eliminates extra software costs. CANopen’s standardized communication protocols also reduce the need for custom integration work.

Indirect Costs

Indirect costs can impact the total cost of ownership. These costs include:

Downtime: Upgrades may require temporary shutdowns. CANopen’s faster installation process minimizes service interruptions.

Training: Staff must learn new procedures. CANopen’s user-friendly interface shortens training periods.

Maintenance: CANopen systems often provide better diagnostics. This feature reduces troubleshooting time and maintenance expenses.

Future Upgrades: CANopen’s open standard supports easy expansion. Organizations avoid costly proprietary upgrades.

Tip: Planning upgrades during scheduled maintenance windows can further reduce downtime costs.

Cost Comparison

A direct comparison between legacy and CANopen upgrades highlights the financial benefits. CANopen systems typically offer:

Lower initial hardware costs

Reduced installation and configuration expenses

Fewer indirect costs due to faster deployment and easier maintenance

Cost Category | Legacy System | CANopen System |

|---|---|---|

Hardware | High | Moderate |

Installation | Complex | Simple |

Software | Custom | Standardized |

Downtime | Longer | Shorter |

Training | Extensive | Minimal |

Maintenance | Reactive | Proactive |

Organizations that upgrade their Telecom Cabinet Power Controller to CANopen often see a rapid return on investment. The combination of lower hardware costs, simplified installation, and reduced indirect expenses makes CANopen a cost-effective choice for telecom infrastructure modernization.

Decision Checklist

Technical Readiness

Organizations must evaluate their technical infrastructure before upgrading to CANopen. They should confirm compatibility with IEC 61131-3 software design standards and adopt model-based design approaches for system-level modeling. Verification and validation according to ISO 26262 and EN 62061 standards ensure functional safety and high-integrity software development. These steps help maintain robust and compliant systems.

Key technical prerequisites include:

Selection of an operating system compatible with CANopen and IEC 61131-3, such as Linux or Windows CE.

Industrial PC hardware that meets EMC, EMI, and ESD standards to prevent interference and ensure reliability.

Use of fanless cooling, solid-state memory, and low-power consumption hardware for durability.

Enclosures rated for environmental conditions, like IP65 for outdoor installations.

Long-term availability and reliability of IPC components to support lifecycle management.

Suppliers with expertise in hardware/software integration and support for CANopen protocols.

Diagnostic capabilities and network integration features inherent to CANopen.

Gateways or protocol converters for integration with existing networks.

Tip: Slim, DIN-rail mountable hardware and no-programming configuration tools simplify installation and reduce complexity.

Financial Review

A thorough financial review helps organizations understand the total cost of ownership. They should compare initial hardware investments, installation expenses, and ongoing maintenance costs. CANopen upgrades often reduce hardware and installation costs due to modular designs and simplified configuration. Organizations should also consider licensing fees for configuration software and training costs for staff.

Cost Factor | Legacy System | CANopen Upgrade |

|---|---|---|

Hardware | High | Moderate |

Installation | Complex | Simple |

Maintenance | Reactive | Proactive |

Training | Extensive | Minimal |

Note: Lifecycle management and network updates provided by suppliers can further reduce long-term expenses.

Risk Factors

Risk assessment is essential for a successful upgrade. Organizations should identify potential technical and operational risks, such as compatibility issues, downtime during installation, and staff adaptation to new systems. They must verify compliance with certifications like CE and UL to ensure safety and reliability. Using gateways that do not require PLC card slots and supporting fast cyclic I/O data transfer can minimize integration risks.

Common risk factors include:

Communication errors or unsupported protocols

Environmental challenges affecting hardware

Delays due to complex configuration or insufficient training

Reliability of supplier support and network updates

Organizations should plan upgrades during scheduled maintenance windows to minimize service disruptions and ensure a smooth transition from legacy systems to CANopen.

Upgrading a Telecom Cabinet Power Controller to CANopen delivers clear advantages in compatibility and cost savings. CANopen simplifies integration, reduces hardware expenses, and streamlines maintenance. Decision-makers should follow a step-by-step process: assess current systems, test compatibility, analyze costs, and plan upgrades.

Regularly reviewing technology ensures the Telecom Cabinet Power Controller remains efficient as industry standards evolve.

FAQ

What is the main benefit of upgrading to CANopen?

CANopen provides standardized communication, which simplifies integration and maintenance. Service providers can reduce hardware costs and improve system reliability. The open protocol also supports future expansion.

Can existing cabinet wiring be reused with CANopen controllers?

Most CANopen upgrades allow reuse of existing wiring. Technicians should verify cable quality and compatibility with CANopen standards. This approach helps reduce installation time and costs.

How long does a typical CANopen upgrade take?

A standard upgrade takes several hours to a few days. The timeline depends on cabinet complexity and staff experience. Planning and preparation help minimize downtime.

Do technicians need special training for CANopen systems?

Most technicians learn CANopen basics quickly. Configuration software uses intuitive interfaces. Short training sessions or vendor-provided tutorials usually suffice.

What ongoing maintenance does a CANopen system require?

CANopen systems need regular firmware updates and periodic diagnostics. Built-in monitoring tools help identify issues early. This proactive approach reduces long-term maintenance costs.

See Also

Essential Outdoor Cabinet Standards For Telecom Communication Gear

Complete Handbook On Wiring And Cable Choices For Telecom Cabinets

Exploring The Function Of Outdoor Cabinets In Telecom Networks

Steps To Guarantee Stable Power Delivery Inside Telecom Cabinets

Evaluating Various Cooling Techniques Used In Telecom Cabinet Systems

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA