What Parameters Should Telecom Cabinet Power Controllers Monitor? Full Analysis of Voltage/Current/Temperature/Load Rate Monitoring Value

You rely on your Telecom Cabinet Power Controller to maintain stable operations in demanding environments. Monitoring electrical and environmental parameters ensures performance and reliability.

Effective monitoring includes voltage, current, temperature, humidity, airflow, water leaks, vibration, battery health, and fuse status.

Upgrading your system to track all critical values protects equipment and supports uninterrupted telecom service.

Key Takeaways

Monitor voltage closely to protect equipment from power surges and drops, keeping it within the safe range around -48VDC.

Track current and load rates to prevent overloads, balance power use, and avoid costly equipment damage.

Keep temperature and humidity within recommended limits to prevent overheating, corrosion, and equipment failure.

Use airflow and water leak sensors to maintain proper cooling and detect moisture early, preventing shutdowns and damage.

Regularly check vibration, battery health, and fuse status to catch physical issues, ensure backup power, and avoid electrical faults.

1. Voltage Monitoring

Importance

You must monitor voltage in your Telecom Cabinet Power Controller to maintain safe and reliable operations. Voltage monitoring protects sensitive equipment from damage caused by power surges, drops, or irregular supply. The telecommunications industry relies on a standardized -48VDC power supply. This standard balances power delivery and safety, as circuits operating at or below 50V DC are generally considered safe for human interaction. Monitoring voltage at the DC power distribution units (PDUs) gives you direct insight into the health of your network’s power infrastructure.

Tip: Consistent voltage monitoring helps you prevent unexpected downtime and costly repairs.

Key Values

You should focus on the following voltage thresholds to ensure optimal performance:

Standard Operating Voltage: -48VDC, recognized as safe and efficient for telecom cabinets.

Safe Range: -38.4V to -57.6V (typically ±20% of the standard).

Common Range: -36V to -72V, depending on equipment requirements.

Negative Voltage: -48VDC minimizes electric shock risk and complies with safety standards.

Grounding: Grounding the positive terminal prevents corrosion and extends equipment life.

Voltage Level | Safety | Efficiency | Compatibility |

|---|---|---|---|

-48VDC | ✅ | ✅ | ✅ |

24VDC | ⚠️ | ❌ | ❌ |

110VDC | ❌ | ⚠️ | ❌ |

Fluctuations

Voltage fluctuations can disrupt telecom operations. You need to watch for deviations outside the recommended range. Sudden drops may signal battery failure or overloaded circuits. Spikes can damage hardware or cause system instability. By tracking voltage trends, you can identify problems early and take corrective action before they affect service.

Monitor for drops below -38.4V or spikes above -57.6V.

Investigate persistent fluctuations to prevent equipment stress.

Use remote monitoring to receive alerts and respond quickly.

Regular voltage monitoring ensures your telecom cabinet remains safe, efficient, and reliable.

2. Current and Load Monitoring

Current Tracking

You need to track current in your Telecom Cabinet Power Controller to maintain safe operation and prevent equipment stress. Current monitoring helps you detect abnormal consumption, short circuits, or faulty devices. By measuring the current drawn by each circuit, you can quickly identify issues before they escalate.

Identify sudden increases in current that may signal a short circuit.

Spot gradual rises that indicate aging equipment or poor connections.

Compare current readings across different circuits for balanced load distribution.

Tip: Use real-time current monitoring to receive instant alerts and take action before problems affect your network.

Load Rate

Understanding the load rate allows you to optimize the performance of your power system. The load rate shows the percentage of total capacity in use. Monitoring this value helps you avoid overloading and ensures efficient energy use.

Calculate load rate as:

Load Rate (%) = (Actual Load / Rated Capacity) × 100Keep the load rate within 60-80% for best reliability.

Review load rate trends to plan for future expansion or upgrades.

Load Rate (%) | Status | Action Needed |

|---|---|---|

0-60 | Underutilized | Consider scaling |

60-80 | Optimal | Maintain settings |

80-100 | High Risk | Reduce load |

Overload Prevention

You must prevent overloads to protect your telecom equipment and avoid service interruptions. Overloads can cause overheating, tripped breakers, or even fires. Your monitoring system should provide early warnings and automatic shutdown features.

Set alarms for current or load rate thresholds.

Schedule regular inspections based on monitoring data.

Use historical data to predict and prevent overload scenarios.

Proactive overload prevention extends equipment life and reduces maintenance costs.

3. Temperature and Humidity

Temperature Control

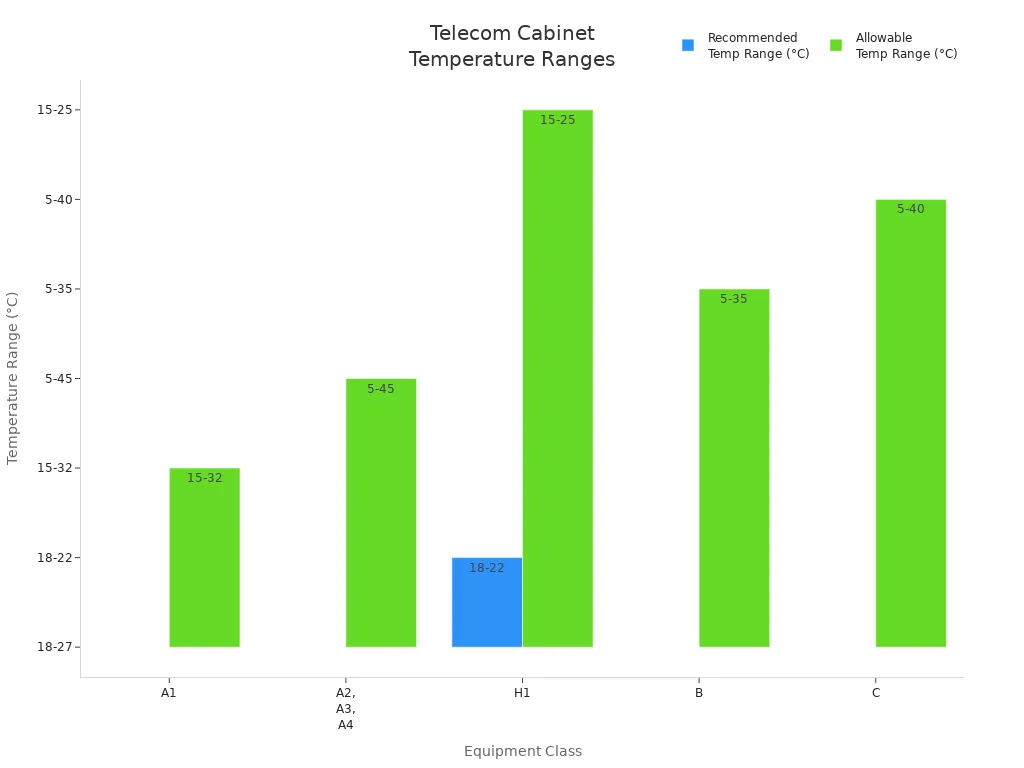

You must monitor temperature inside your telecom cabinet to prevent overheating and ensure reliable operation. Excess heat causes performance degradation, component fatigue, and equipment failure. The NEBS standard recommends keeping the temperature between 41°F and 104°F (5°C to 40°C). ASHRAE guidelines further specify safe ranges for different equipment classes. You should measure temperature at the IT equipment inlet, not just the room, for accurate readings. Cooling fans and DC air conditioners respond to rising temperatures by circulating air and removing heat, which protects sensitive electronics.

Equipment Class | Recommended Temperature Range (°C) | Recommended Temperature Range (°F) | Allowable Temperature Range (°C) | Allowable Temperature Range (°F) |

|---|---|---|---|---|

A1 | 18 to 27 | 64.4 to 80.6 | 15 to 32 | 59 to 89.6 |

A2, A3, A4 | 18 to 27 | 64.4 to 80.6 | 5 to 45 | 41 to 113 |

B | N/A | N/A | 5 to 35 | 41 to 95 |

C | N/A | N/A | 5 to 40 | 41 to 104 |

H1 | 18 to 22 | 64.4 to 71.6 | 15 to 25 | 59 to 77 |

Tip: Regular temperature monitoring in your Telecom Cabinet Power Controller enables targeted cooling and extends equipment lifespan.

Humidity Risks

Humidity poses serious risks to telecom cabinet components. High humidity leads to moisture absorption, which weakens materials and increases fatigue cracking. Metals and alloys corrode faster, reducing structural integrity. Swelling and shrinkage from moisture changes cause dimensional instability and fatigue cracks. Electronic components, including circuit boards, degrade in performance and durability when exposed to humidity. You should keep relative humidity between 20% and 80% RH, with an optimal range of 45%-55%. Experts recommend keeping RH below 60% to prevent corrosion, especially for copper and silver parts.

Moisture absorption reduces material strength.

Corrosion accelerates in metals and alloys.

Swelling and shrinkage cause cracks and instability.

Electronic components lose performance and durability.

Environmental chambers test resistance to humidity and temperature.

Note: Maintaining humidity below 50% helps prevent condensation and corrosion in sensitive equipment.

Environmental Stability

Stable temperature and humidity levels inside your telecom cabinet protect equipment and reduce failure rates. High NEMA or IP-rated enclosures defend against dust, moisture, and corrosive agents. Integrated climate control features maintain optimal conditions, preventing overheating and condensation. Robust cabinet construction shields against impacts and extreme weather. Active cooling prevents condensation, which can cause short circuits and corrosion. Stable environments support high-density setups, prevent hotspots, and extend equipment life. Automated climate control reduces repair frequency and downtime, lowering long-term costs.

High-rated enclosures block dust and moisture.

Climate control maintains optimal temperature and humidity.

Active cooling prevents condensation and short circuits.

Stable environments extend equipment lifespan and minimize downtime.

4. Airflow and Water Leak Detection

Airflow Monitoring

You need to monitor airflow inside your telecom cabinet to keep equipment cool and running efficiently. Proper airflow prevents hotspots and ensures that cooling systems work as intended. When you track airflow, you can spot blocked vents, failing fans, or dust buildup before these issues cause overheating. Many professionals use airflow sensors to measure the speed and direction of air movement. These sensors help you confirm that every part of the cabinet receives enough cooling.

Detect blocked or restricted airflow early.

Identify malfunctioning fans or clogged filters.

Maintain even temperature distribution across all equipment.

Tip: Regular airflow checks help you avoid unexpected shutdowns and extend the life of your electronics.

Water Leak Sensors

Water leaks pose a serious threat to telecom cabinets. Even a small leak can cause short circuits, corrosion, or total equipment failure. You should install water leak sensors at the base of your cabinet and near any entry points for cables or pipes. These sensors alert you immediately if they detect moisture, giving you time to act before damage occurs.

Place sensors in areas most likely to collect water.

Receive instant alerts for rapid response.

Prevent costly repairs and downtime from water damage.

Note: Early detection of leaks protects your investment and keeps your network reliable.

Cooling Optimization

You can optimize cooling by integrating airflow and water leak monitoring with your cabinet’s climate control system. When you combine these sensors with automated cooling, you ensure that fans and air conditioners only run when needed. This approach saves energy and reduces wear on cooling equipment. You also gain the ability to adjust cooling based on real-time data, which keeps conditions stable and efficient.

Use sensor data to control fan speed and cooling cycles.

Lower energy costs by avoiding unnecessary cooling.

Improve system reliability with proactive adjustments.

Efficient cooling not only saves money but also boosts the performance and lifespan of your telecom equipment.

5. Vibration, Battery, and Fuse Status

Vibration Alerts

You should monitor vibration in your telecom cabinet to detect physical disturbances that threaten equipment stability. Sudden shocks or ongoing vibrations can loosen connections, damage sensitive electronics, or signal unauthorized access. Vibration sensors provide early warnings, allowing you to investigate and address issues before they escalate. By tracking vibration patterns, you can prevent costly repairs and maintain uninterrupted service.

Detect unauthorized access or tampering.

Identify equipment misalignment or mechanical faults.

Reduce the risk of component failure due to physical stress.

Tip: Regular vibration monitoring helps you maintain a secure and stable operating environment.

Battery Health

Backup batteries serve as the lifeline during power outages. You need to assess battery health continuously to ensure reliable backup power. Key indicators include voltage, internal resistance, and temperature. Monitoring these values in real time allows you to spot early signs of battery degradation, such as overheating or increased resistance, which often lead to reduced capacity and efficiency.

Track voltage, internal resistance, and temperature for each battery.

Receive alerts for abnormal readings or overheating.

Schedule timely maintenance or replacement to avoid unexpected failures.

Maintain optimal environmental conditions (20°C to 25°C) for battery longevity.

Aspect | Details |

|---|---|

Failure Rate | 62% of cell tower failures are power related; 80% of those stem from battery issues. |

Risks | Inadequate monitoring can cause costly downtime, safety hazards, and battery fires. |

Best Practice | Use remote, continuous monitoring and intelligent battery management to extend battery life and reduce costs. |

Fuse and Power Failure

Fuses protect your telecom cabinet from electrical faults. Common causes of fuse failures include frayed wires, poor sensor design, and moisture intrusion. These issues can lead to short circuits, rapid temperature rise, or even fires. Monitoring fuse status allows you to detect abnormal conditions early and take preventive action.

Identify frayed or loose wires before they cause shorts.

Detect moisture or hydrogen buildup that could trigger fuse failure.

Respond quickly to abnormal sensor readings to prevent site outages.

Note: Early detection of fuse issues helps you avoid catastrophic damage and service interruptions.

Telecom Cabinet Power Controller Integration

Integrating all monitoring functions into your Telecom Cabinet Power Controller enhances reliability and maintenance efficiency. Real-time performance tracking, automated alerts, and predictive analytics enable you to respond quickly to faults and optimize maintenance schedules.

Benefit | Description |

|---|---|

Real-Time Tracking | Monitor power, battery, and environment remotely, reducing site visits. |

Early Fault Detection | Automated alerts speed up response and minimize downtime. |

Predictive Maintenance | AI-driven insights help you plan maintenance before failures occur. |

Cost Reduction | Integrated systems lower operational costs and improve uptime. |

Integrated monitoring ensures your telecom infrastructure remains resilient, efficient, and ready for future demands.

You should monitor a comprehensive set of parameters, including temperature, humidity, intrusion, power system status, and connectivity. Real-time monitoring with AI and IoT reduces downtime and maintenance costs by predicting failures early.

Best practices for advanced monitoring include:

Calculate total power needs and plan for growth.

Choose scalable, standards-compliant solutions.

Integrate remote monitoring and predictive analytics.

Schedule regular audits and adapt to new technologies.

Stay proactive and update your monitoring strategies as telecom operations and regulations evolve.

FAQ

What is the ideal temperature range for telecom cabinets?

You should keep the temperature between 41°F and 104°F (5°C to 40°C). This range protects sensitive electronics and ensures reliable operation. Regular monitoring helps you avoid overheating and equipment failure.

How often should you check battery health?

Check battery health monthly.

Use remote monitoring for real-time alerts.

Replace batteries showing signs of degradation.

Schedule maintenance based on usage and age.

Which parameters help prevent water damage?

Parameter | Purpose |

|---|---|

Water Leak | Detects moisture early |

Humidity | Prevents condensation |

Airflow | Reduces dampness |

You should install sensors for each parameter to protect your equipment.

Why is vibration monitoring important?

Vibration monitoring helps you detect physical disturbances, unauthorized access, and equipment misalignment. Early alerts allow you to address issues before they cause costly repairs or service interruptions.

See Also

Best Practices For Monitoring Outdoor Telecom Cabinets Effectively

Methods To Calculate Power Systems And Batteries For Telecom Cabinets

Exploring Various Cooling Techniques Used In Telecom Cabinets

Steps To Guarantee Consistent Power Supply For Telecom Cabinets

Key Features You Should Understand About Telecom Power Supplies

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA