5-Step Practical Guide to Building a Telecom Cabinet Power Controller Monitoring System (Tool Recommendations Included)

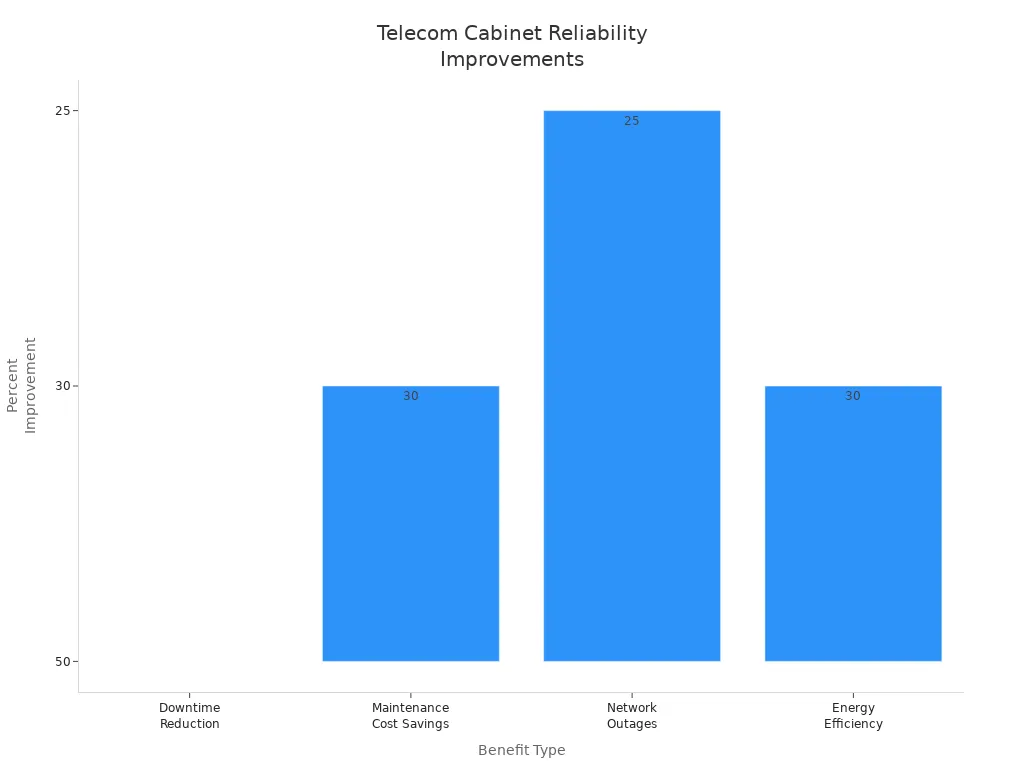

Maintaining reliable telecom operations requires more than just sturdy equipment. You need to monitor both power and environmental factors to keep your Telecom Cabinet Power Controller system running smoothly. Real-time monitoring reduces downtime by up to 50% and cuts maintenance costs by 30%.

Benefit Type | Quantified Improvement | Effect on Telecom Cabinet Reliability |

|---|---|---|

Downtime Reduction | Up to 50% decrease | Enhances network uptime and reduces service interruptions |

Maintenance Cost Savings | 30% reduction | Lowers operational expenses and supports proactive maintenance |

Network Outages | 25% fewer outages | Improves service continuity and customer satisfaction |

Energy Efficiency | 30% energy savings | Reduces cooling and electricity costs |

With the right approach and tools, you can achieve early fault detection, respond quickly to issues, and ensure stable telecom services.

Key Takeaways

Set clear monitoring goals like stable power, overload protection, and real-time alerts to reduce downtime and save costs.

Choose intelligent power controllers and sensors that fit your cabinet’s needs and support remote management for better control.

Use reliable software with dashboards and alerts to monitor multiple cabinets from one place and integrate with building systems.

Follow proper wiring standards and organize cables carefully to ensure safety and simplify maintenance.

Test and maintain your system regularly to catch issues early, keep sensors accurate, and extend equipment life.

Define Requirements

Monitoring Goals

You need to set clear monitoring goals before building your Telecom Cabinet Power Controller monitoring system. Most commercial deployments aim for stable and efficient power distribution, overload protection, and real-time monitoring. Modern systems use AI and IoT technologies to predict failures and optimize energy use. These features help you reduce downtime and repair costs. You can manage power remotely and analyze trends to spot problems early.

Monitoring Goal | Purpose / Benefit |

|---|---|

Stable and efficient power distribution | Keeps telecom equipment running without interruption. |

Overload protection | Prevents damage from power surges or excessive loads. |

Real-time monitoring | Detects power issues quickly for fast response. |

Remote control capabilities | Lets you adjust power settings from anywhere. |

Trend reporting | Helps you find problems before they become serious. |

You should also consider centralizing monitoring for all cabinets. This approach gives you a single platform for alerts about power failures, temperature spikes, or unauthorized access. You avoid fragmented dashboards and keep control over your system without extra subscriptions.

Key Parameters

Identify the key parameters you want to monitor. Focus on electrical metrics like current, voltage, and energy consumption. Track environmental factors such as temperature, humidity, and airflow. Security monitoring is important for detecting unauthorized access or smoke. Battery health checks help prevent failures and keep backup systems ready.

Parameter Category | Parameters Monitored | Purpose/Importance |

|---|---|---|

Electrical Metrics | Current, Voltage, Power, Energy Consumption | Prevent overloads and ensure safe power flow |

Environmental Factors | Temperature, Humidity, Airflow | Protect equipment and maintain cooling |

Security Monitoring | Access status, Locks, CCTV | Guard against unauthorized entry |

Battery Health | Voltage, Current, State of Charge | Ensure backup power is reliable |

Evaluate the number and location of your telecom cabinets. Check for environmental risks like temperature swings, humidity, and water leaks. Make sure your system meets standards such as NEMA, IP ratings, and NEBS compliance. Set performance goals for early problem detection, remote control, and energy savings. These steps help you build a reliable and efficient monitoring system.

Select Telecom Cabinet Power Controller Hardware

Power Controllers

Choosing the right power controller is essential for reliable telecom cabinet operation. You should look for intelligent PDUs that offer real-time monitoring, remote management, and advanced circuit protection. These features help you prevent downtime and optimize energy use. The ESTEL series stands out for telecom applications. Each model offers unique strengths:

PDU Model | Key Features | Reliability Highlights |

|---|---|---|

ESTEL Model D | Remote control, real-time monitoring, protection | Reduces energy costs, ideal for remote/disaster sites |

ESTEL Model E | Dynamic load balancing, monitoring, protection | Improves efficiency, prevents overheating |

ESTEL Model C | Precise management, advanced monitoring | Detailed metrics, reliable for high-density cabinets |

ESTEL Model F | Surge protection, durability | Minimizes downtime, protects against voltage spikes |

ESTEL Model B | Basic tracking, plug-and-play simplicity | Cost-effective, reliable for small-scale setups |

ESTEL Model A | Scheduling, recovery modes, scalability | Supports growing infrastructures |

Tip: Select a power controller that matches your cabinet’s power load and outlet needs. Consider future expansion and look for redundancy features to prevent outages.

Intelligent PDUs, such as the ESTEL series, provide remote management, environmental sensing, and alert systems. These capabilities support proactive maintenance and stable power distribution in your Telecom Cabinet Power Controller setup.

Sensors and PDUs

You need sensors and PDUs that monitor both power and environmental conditions. Modular and scalable PDUs allow you to upgrade equipment without replacing the entire cabinet. Look for models with hot-swappable breakers and remote telemetry integration (SNMP, Modbus RTU) for real-time data.

Key sensors for telecom cabinets include:

Temperature sensors (place at top, middle, and bottom of rack)

Humidity sensors (maintain ASHRAE ranges)

Water leak sensors (near cooling units and under floors)

Vibration sensors (detect seismic activity or faults)

Dust/particle sensors (monitor airborne contaminants)

Security sensors (access, locks, CCTV)

Legrand’s SmartSensors offer plug-and-play integration with intelligent rack PDUs, making installation easy and data collection accurate. IoT-ready PDUs support advanced analytics and predictive maintenance, helping you prevent outages and improve efficiency.

Note: For outdoor cabinets, select enclosures made from stainless steel or aluminum for durability. Ensure compliance with NEMA and IP ratings for protection against dust, water, and impact. Use HVAC enclosures with temperature-controlled fans and secure locking systems to safeguard your Telecom Cabinet Power Controller hardware.

Set Up Monitoring Software

Software Options

You need reliable software to monitor your Telecom Cabinet Power Controller system in real time. Top-rated platforms offer dashboards, alerts, and integration with building management systems. The table below compares leading options based on user reviews:

Software Platform | User Ratings (G2 / Capterra) | Key Features | Limitations |

|---|---|---|---|

ManageEngine OpManager | 4.5 / 4.7 | Network & power monitoring, asset tracking, dashboards | Limited scalability, less comprehensive for complex environments |

IBM Turbonomic | 4.5 / N/A | AI-driven resource & power management, lifecycle management | Requires specialized training, annual pricing only |

Sunbird DCIM | N/A | Powerful monitoring, user-friendly dashboards, effective support | Minor programming support delays |

Sunbird DCIM stands out for its intuitive dashboards and strong user satisfaction. Many telecom professionals find it easy to use and effective for monitoring equipment. ManageEngine OpManager and IBM Turbonomic also provide robust monitoring and asset management. For advanced visual monitoring, Deepomatic uses AI to deliver image-based insights, which can help with asset verification and error detection.

When you select a platform, check for features like remote access, customizable alerts, and compatibility with your existing hardware. Integration with BMS allows you to manage HVAC, security, and energy systems from a single interface. This centralized approach improves operational efficiency and security.

Configuration

To set up centralized monitoring, follow these steps:

Assess your site using digital models or drone imagery to confirm equipment placement and access.

Choose hardware that supports secure protocols such as Modbus and TLS encryption.

Establish reliable connectivity using cellular, satellite, or dual-mode devices for redundancy.

Implement security measures like role-based access control and regular audits.

Prepare the cabinet by clearing space and checking dimensions for your monitoring equipment.

Mount and connect PDUs, ensuring proper alignment and voltage matching.

Label cables for easy maintenance and troubleshooting.

Test the system for power delivery, communication, and security under different conditions.

Set up routine maintenance, including software updates and performance checks.

Tip: Use cloud-based monitoring for remote sites. This approach supports centralized oversight and reduces the need for on-site visits.

Integration with building management systems brings all your monitoring data into one dashboard. You gain centralized control, remote access, and easier expansion for new sensors or sites. This setup helps you maintain a reliable Telecom Cabinet Power Controller system and respond quickly to any issues.

Integrate and Connect

Wiring

Proper wiring forms the backbone of a reliable Telecom Cabinet Power Controller monitoring system. You should follow established wiring standards like TIA/EIA-568-A and TIA/EIA-607 to ensure safe telecommunications wiring and grounding. Use double-insulated cables to boost electrical safety. Connect every component to a common grounding point with the correct gauge copper wires. Inspect these connections regularly for corrosion or looseness.

Organize and label cables at both ends with durable, color-coded labels. This step makes maintenance and troubleshooting much easier. Shielded twisted pair or coaxial cables help reduce electromagnetic interference. Calculate power requirements carefully to avoid circuit overloads and select wire sizes that prevent overheating. Design the cabinet layout to minimize cable clutter. Use cable trays, ties, and conduits for neat cable management.

Tip: Effective cable management improves safety and speeds up repairs.

Monthly inspections and tests using multimeters and cable testers help you catch damaged wires early. Replace any faulty wiring promptly to maintain system integrity.

Integration

When integrating power controllers, sensors, and PDUs, you need to focus on secure connections and environmental protection. Implement robust access controls such as biometric authentication and surveillance. Encrypt all data to protect confidentiality. Upgrade legacy systems to support modern security protocols and conduct regular system updates.

For outdoor cabinets, inspect environmental seals and gaskets often. Make sure cabinet doors close securely and locks work properly to prevent moisture, dust, and unauthorized access. Cabinets should withstand rain, snow, wind-blown dust, and UV radiation. Use corrosion-resistant materials like stainless steel or aluminum. Install temperature and humidity control systems to protect sensitive electronics.

Maintain detailed records of inspections, maintenance, and repairs. Engage qualified professionals for complex repairs. Modular cabinet designs allow easy maintenance and quick component replacement. Remote monitoring capabilities let you track real-time status and environmental parameters, ensuring your Telecom Cabinet Power Controller system remains reliable in any condition.

Test and Maintain

Testing

You need to test your Telecom Cabinet Power Controller monitoring system before you put it into service. Start with acceptance testing for all new PDU installations. Inspect and test each component to confirm reliability and safety. Follow these steps for a thorough check:

Inspect each PDU and sensor visually for damage or loose connections.

Perform electrical tests on circuit breakers, transformers, and bus connections. Use primary and secondary injection testing, insulation resistance checks, and contact resistance measurements.

Test the grounding system with a two-point continuity check.

Verify metering accuracy by injecting known voltages and currents.

Run operational checks to confirm that sensors, controllers, and alarms interact correctly.

Always de-energize equipment before testing, and use certified technicians for safety.

After installation, schedule professional inspections at least once a year. Test rectifiers, batteries, and sensors regularly. Calibrate sensors such as temperature, humidity, smoke, and water leak detectors using reference standards. Document all test results and calibration dates for compliance and future reference.

Tip: Continuous real-time monitoring helps you catch issues early and maintain optimal performance.

Maintenance

Regular maintenance keeps your monitoring system reliable and extends its lifespan. Inspect the cabinet visually at least twice a year. Look for corrosion, loose fasteners, and panel damage. Clean components and remove debris to prevent overheating. Check cables and electrical connections every quarter. Replace any damaged wires right away.

Calibrate sensors following manufacturer guidelines. For example, use a dry-well calibrator for temperature sensors and a controlled humidity chamber for humidity sensors. Adjust readings if they fall outside the specified range. Record all calibration activities.

Keep detailed records of inspections, cleaning, and repairs. Use remote monitoring tools to track system performance and receive alerts. Schedule preventive maintenance for batteries, surge protection, and HVAC systems. Train your staff on system setup, troubleshooting, and early fault detection. Well-trained personnel can respond quickly to alerts and reduce downtime.

Note: Ongoing training and support ensure your team can manage new technologies and maintain your Telecom Cabinet Power Controller system efficiently.

You can build a reliable monitoring system by following these five steps. A comprehensive approach delivers benefits such as space-efficient design, future-proofing, and advanced security. Selecting the right tools and performing regular maintenance ensures long-term reliability and reduces downtime. Real-time alerts and predictive maintenance help you prevent costly outages and extend equipment life.

Start your project with confidence, knowing that proactive monitoring supports network uptime and operational savings.

FAQ

What tools do I need to start monitoring my telecom cabinet?

You need intelligent PDUs, sensors for temperature and humidity, reliable wiring, and monitoring software. Choose tools that match your cabinet size and environment. Start with basic models, then upgrade as your needs grow.

How often should I test and calibrate sensors?

Test sensors every quarter. Calibrate temperature and humidity sensors twice a year. Record each calibration date. Regular checks help you catch problems early and keep your system accurate.

Can I monitor multiple cabinets from one dashboard?

Yes. Most modern monitoring software lets you view data from several cabinets on a single dashboard. You can set alerts for each cabinet and manage them remotely.

What should I do if I find a wiring issue during inspection?

Turn off power before touching any wires. Replace damaged cables right away. Use labeled, shielded wires for safety. If you see corrosion or loose connections, fix them before restarting the system.

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA