New Feature Launch for Telecom Cabinet Power Controllers: How Smart Alerts + Remote Control Reduce O&M Costs by 30%?

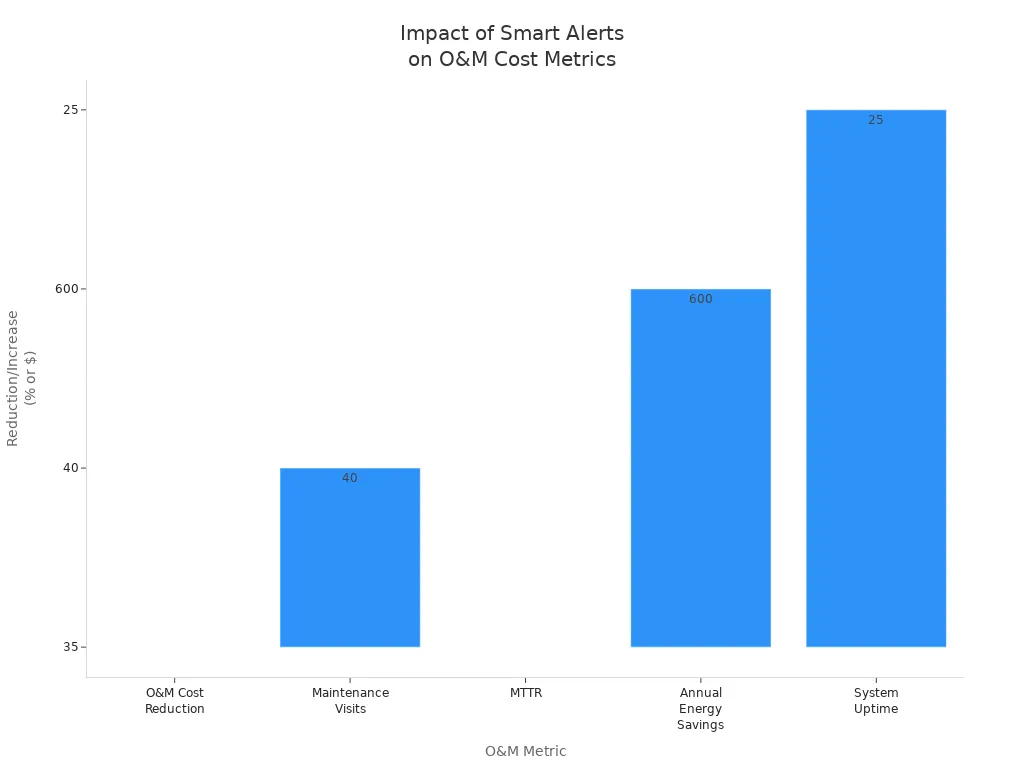

Smart alerts and remote control in Telecom Cabinet Power Controller systems empower you to cut operational and maintenance costs by up to 30%. You receive instant notifications for abnormal operations, which enables rapid troubleshooting and minimizes downtime. Remote diagnostics let you address faults without traveling to the site, reducing maintenance visits by 40%. The following table highlights the impact of these technologies:

Metric | Impact on O&M Costs | Explanation |

|---|---|---|

O&M Cost Reduction | Achieved through energy savings, improved rectifier efficiency, and hybrid power integration. | |

Maintenance Visits | Reduced by up to 40% | Remote monitoring and smart alerts enable fewer on-site inspections. |

Mean Time to Repair (MTTR) | Reduced by 35% | Automated alerts and hot-swappable modules speed up fault response. |

Annual Energy Savings per Cabinet | Over $600 saved | Efficiency improvements reduce electricity consumption by nearly 4,000 kWh annually. |

System Uptime | Increased by 25% | Predictive maintenance and remote control minimize downtime and service interruptions. |

Key Takeaways

Smart alerts notify you instantly about problems, helping your team fix issues quickly and reduce downtime.

Remote diagnostics let you check and fix equipment from anywhere, cutting maintenance visits by up to 40%.

Using smart monitoring and remote control can lower your operational costs by up to 30%, saving money on repairs and energy.

Faster response times and predictive maintenance improve network reliability and keep your service running smoothly.

Following best practices and training your team ensures safe, efficient use of these smart systems for long-term benefits.

Cost Reduction

Instant Smart Alerts

You gain a significant advantage when you deploy instant smart alerts in your Telecom Cabinet Power Controller systems. These alerts notify your operations and maintenance teams the moment abnormal conditions arise. You receive notifications through multiple channels, such as email, SMS, push notifications, and incident management platforms. This immediate delivery ensures your team can act quickly, reducing downtime and preventing minor issues from escalating.

Smart alerts use AI-driven predictive maintenance and real-time monitoring to detect anomalies like voltage fluctuations, temperature spikes, and battery health problems. You can address these issues before they cause failures. The result is a more reliable network and fewer unplanned outages.

Tip: Early detection through smart alerts helps you avoid costly downtime and extends the life of your equipment.

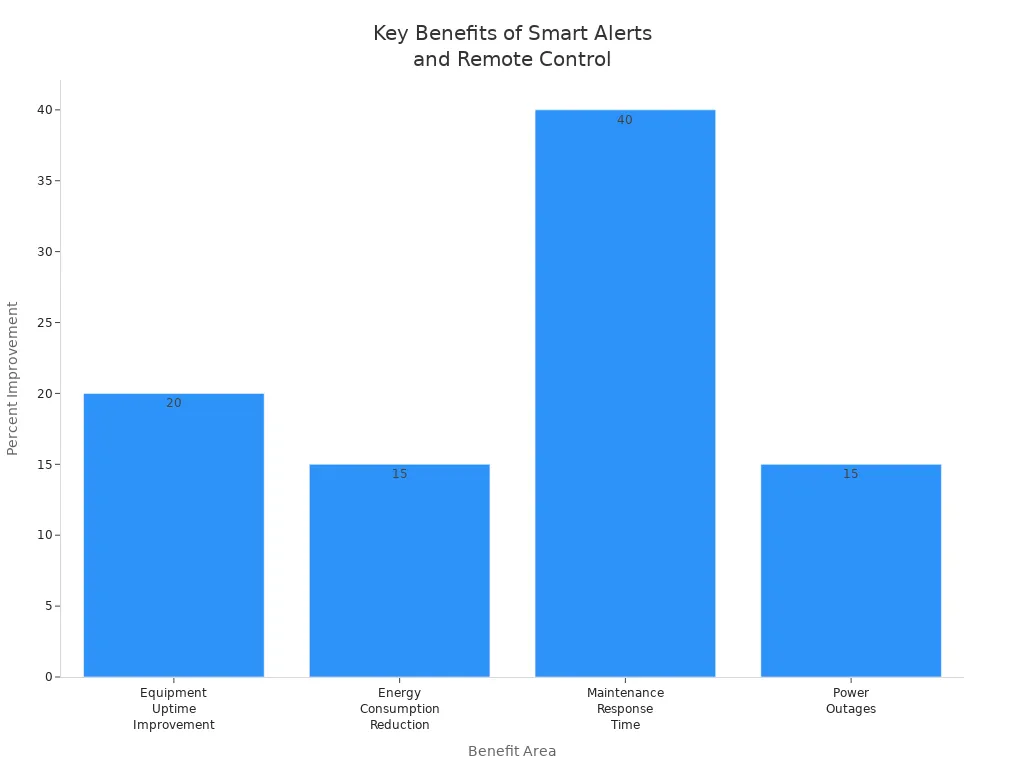

The impact of instant smart alerts is clear:

Benefit Category | Description | Supporting Data |

|---|---|---|

Reduced Downtime | Early detection and predictive maintenance reduce outages | 15% reduction in outages; 20% improvement in uptime; 30% lower maintenance costs |

Operational Efficiency | Centralized dashboards and customizable alerts improve response | Remote monitoring reduced site visits from 4 to 1 per year |

You can see how these features directly contribute to a more efficient and resilient telecom infrastructure.

Remote Diagnostics

Remote diagnostics transform the way you manage your Telecom Cabinet Power Controller. You no longer need to send technicians to remote sites for routine checks or troubleshooting. Instead, you access real-time data and system health reports from a centralized dashboard. This approach allows you to identify faults, monitor battery health, and assess environmental conditions without leaving your office.

Industry reports highlight that IoT-enabled monitoring systems enable predictive maintenance and real-time performance tracking. These capabilities reduce downtime and operational expenses by allowing timely interventions and minimizing unplanned outages. Centralized control eliminates the need for physical access to individual panels, saving time and reducing maintenance costs. You maintain uninterrupted power supply and optimize resource utilization, especially in remote or hard-to-access locations.

Key technical features that enable remote diagnostics include:

Real-time fiber and reflectorless monitoring for rapid fault isolation

Integrated battery health monitoring and scalable PDUs with remote access

IoT devices supporting multiple protocols and edge computing for local data processing

Centralized cloud platforms with real-time dashboards and automated reporting

Secure remote access via Telnet, SSH, or web clients for configuration and troubleshooting

AI-driven analytics for predictive maintenance and anomaly detection

These features allow you to detect faults early, schedule maintenance efficiently, and avoid unnecessary site visits.

Fewer Site Visits

You achieve substantial cost savings by reducing the number of site visits required for maintenance and troubleshooting. Smart alerts and remote control features in your Telecom Cabinet Power Controller let you resolve many issues remotely. For example, remote activation of power-saving algorithms and automated incident handling eliminate the need for physical intervention.

Studies show that remote management can reduce site visits from four to one per year, especially in remote or difficult-to-access locations. This reduction not only lowers operational costs but also decreases travel-related carbon emissions. Real-time power monitoring helps you identify inefficient hardware, leading to energy savings of up to 20%. Enhanced site visibility and automated notifications further improve maintenance efficiency.

Note: Fewer site visits mean less travel, lower fuel consumption, and a smaller environmental footprint for your operations.

By leveraging these advanced features, you support both your bottom line and your sustainability goals. The 30% reduction in O&M costs, supported by industry data and intelligent PDUs, demonstrates the real-world value of adopting smart alerts and remote control in your telecom infrastructure.

Key Benefits

Faster Response

You gain a significant advantage with smart alerts and remote control features. These tools automate incident detection and group related alarms, so you receive notifications almost instantly. You can acknowledge alarms in under a minute, compared to the previous average of 31 hours. This rapid response means you resolve issues before they escalate, keeping your network running smoothly.

Metric | Before Implementation | After Implementation | Impact Description |

|---|---|---|---|

Alarm Acknowledgement Time | 1,889 minutes | Drastic reduction in response time | |

Maintenance Response Time | — | Quicker troubleshooting and repair | |

Employee Morale & Satisfaction | — | Increased | Improved work environment |

Remote access allows your technicians to troubleshoot and manage devices without traveling to the site. Automation of workflows, such as alert generation and ticket creation, further accelerates incident handling. You minimize downtime and improve operational efficiency.

🚀 Tip: Real-time alerts and remote diagnostics help you prevent small issues from becoming major outages.

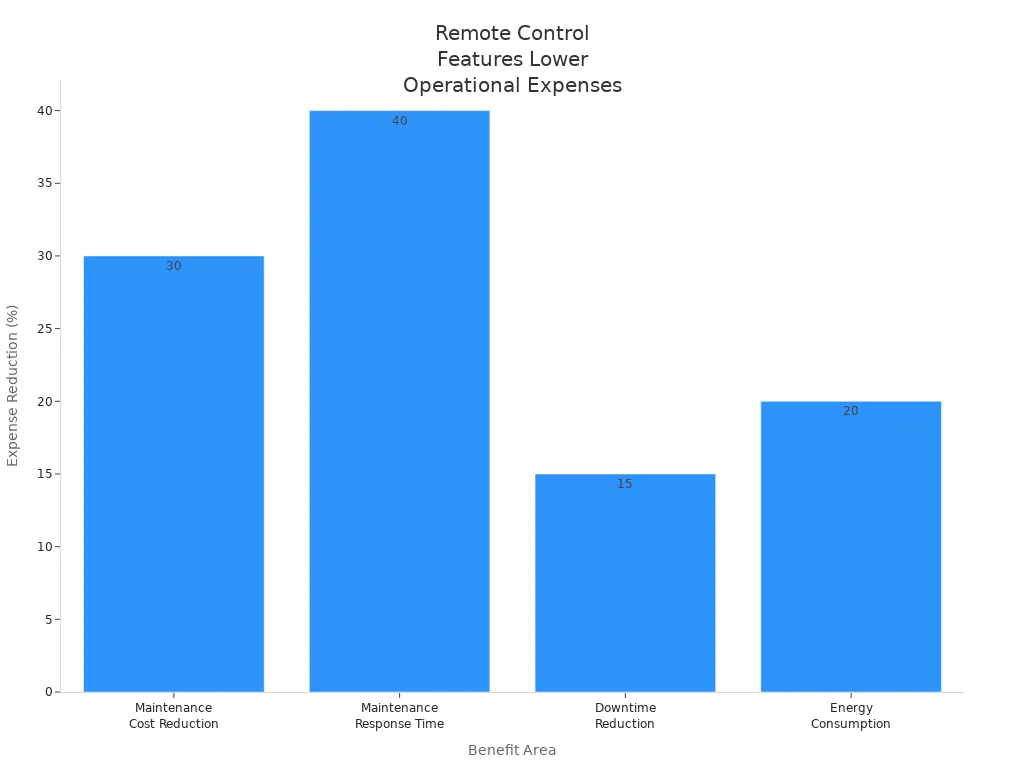

Lower Expenses

You reduce operational expenses by up to 30% when you implement remote control and smart monitoring. Fewer emergency repairs and site visits mean lower labor and transportation costs. Predictive maintenance schedules repairs only when necessary, so you avoid unnecessary work and extend equipment life.

Benefit Area | Impact on Operational Expenses |

|---|---|

Maintenance Cost Reduction | Up to 30% decrease due to fewer emergency repairs and site visits |

Downtime Reduction | 15% less downtime, improving service reliability and cutting costs |

Energy Consumption | Up to 20% savings through smart PDUs and IoT-enabled sensors |

Smart cabinets equipped with remote sensors monitor environmental and security parameters, reducing manual checks. Cloud-based management platforms allow you to oversee multiple sites from one location, minimizing field service interventions.

Real-time alerts prevent major failures and reduce repair costs.

Smart thermal management and fewer truck rolls save on energy and labor.

Improved Reliability

You improve network reliability with early detection of environmental anomalies and power issues. Real-time alerts and predictive maintenance help you address problems before they cause outages. Centralized monitoring reduces the need for physical site visits, lowering labor and maintenance costs.

Business Outcome Metric | Measurable Improvement / Impact |

|---|---|

Downtime reduction | Up to 35% reduction with AI-driven predictive maintenance |

Equipment uptime | 20% improvement using intelligent PDUs |

Maintenance response times | 40% faster response enabling quicker issue resolution |

Battery failure rates | 98% reduction through early anomaly detection |

Remote control of power, security, and environmental systems enhances operational efficiency. You support network expansion in challenging environments and maintain high service quality.

💡 Note: Improved reliability translates directly into better customer satisfaction and long-term cost savings.

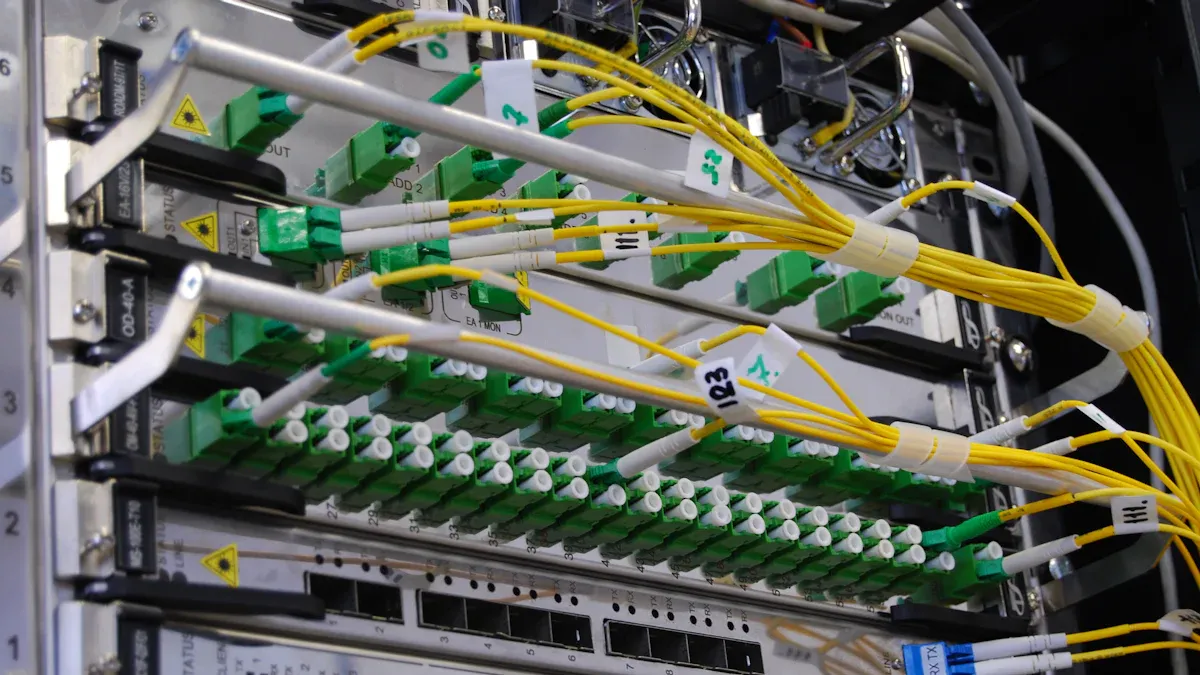

How Telecom Cabinet Power Controller Works

Smart Monitoring

You rely on smart monitoring to maintain optimal performance and reliability in your Telecom Cabinet Power Controller. The system integrates advanced components that automate tasks and deliver real-time data. The following table outlines the main elements that enable smart monitoring:

Component | Role in Smart Monitoring and Functionality |

|---|---|

Microprocessor Controlled Logic | Automates tasks, reducing manual intervention and enabling intelligent control. |

Programmable Microcontroller Unit | Enables remote control and monitoring via Ethernet connectivity. |

Display and Controls | Provides real-time data visualization such as voltage and current for live monitoring. |

Alarm Indicators | Alerts users promptly to problems, facilitating quick issue resolution. |

Protective Controls | Safeguards the system against power surges and overloads, ensuring reliability. |

Thermal & Sound Insulating Materials | Enhances system durability and safety by fireproofing and pest resistance. |

Wiring | Ensures safety and dependable operation through high-quality connections. |

These components work together to automate operations, provide instant alerts, and support remote management. You gain visibility into voltage, current, and environmental conditions, which helps you prevent failures and maintain system health.

Remote Control Features

Remote control features transform how you manage your telecom infrastructure. You access the system through secure modem communication, connecting to a centralized RMS platform. This setup allows you to extract data locally and remotely, download software updates, and upgrade battery management systems. The controller manages all power-related components, including incoming power, consumption, and battery charging. It processes sensor data internally, reducing duplication and conflicts.

You benefit from automated power source switching between grid and generator, thanks to the built-in automatic transfer switch. Data is securely stored on-site and transmitted in timestamped packages for visualization and alarm integration. Security measures protect your remote operations, including up-to-date encryption protocols, access controls, and regular vulnerability assessments. You maintain compliance with industry standards and ensure reliable, faultless monitoring.

🔒 Tip: Regular software updates and strong management practices help you defend against cyber threats and maintain system integrity.

Maintenance Optimization

Smart monitoring and remote diagnostics enable you to optimize maintenance schedules and reduce operational costs. You track rectifier status, battery health, and environmental conditions in real time, minimizing the need for on-site inspections. Automated alert systems notify you immediately of faults, allowing rapid troubleshooting and early intervention.

Real-time remote monitoring reduces unnecessary site visits.

Automated alerts speed up fault response and prevent outages.

Integration with third-party platforms centralizes management and data sharing.

AI-driven predictive maintenance analyzes trends and predicts failures.

Hot-swappable modules and firmware updates improve system stability and uptime.

Modular designs and remote monitoring support efficient scheduling and resource allocation.

Long-term, you see maintenance response times improve by 40%, fewer emergency repairs, and extended equipment life. Remote control capabilities lower costs and boost operational efficiency. Intelligent PDUs and environmental sensors help you balance loads and schedule proactive maintenance. Modular solutions with remote updates ensure your network adapts to future technology changes.

Real-World Impact

Case Studies

You can see the benefits of smart alerts and remote control in real-world deployments. For example, a leading mobile operator in Southeast Asia upgraded its network with a Telecom Cabinet Power Controller. The company managed over 2,000 remote sites. Before the upgrade, the team faced frequent outages and high maintenance costs. After implementing smart monitoring and remote diagnostics, the operator reduced site visits by 38%. The mean time to repair dropped from 12 hours to just 4 hours. Annual O&M costs fell by $500,000.

Another case involved a European tower company. The company installed remote control features across its rural sites. The team used instant alerts to detect power failures and battery issues. As a result, the company improved system uptime by 22%. The team also cut emergency maintenance trips by half. These results show how you can achieve measurable savings and better reliability.

📈 Note: Real-world data confirms that smart features deliver both cost savings and improved network performance.

User Scenarios

You can apply these solutions in many scenarios. If you manage a network in a remote region, you often struggle with access and high travel costs. With a Telecom Cabinet Power Controller, you receive instant alerts for power or temperature issues. You can troubleshoot and reset systems remotely, saving time and money.

If you operate in urban areas, you benefit from predictive maintenance. The system notifies you before a battery fails or a circuit overheats. You schedule repairs only when needed, which reduces downtime and extends equipment life. You also improve customer satisfaction by keeping your network running smoothly.

Remote troubleshooting for hard-to-reach sites

Automated alerts for critical power events

Predictive maintenance for urban networks

Getting Started

Integration Steps

You can deploy smart alerts and remote control in your telecom cabinet power controllers by following a structured approach. Begin by assessing your current infrastructure and identifying compatibility with open protocols such as SNMP. This step prevents vendor lock-in and ensures flexible alarm reporting. Next, select controllers that support remote provisioning and firmware updates. This feature allows you to manage bulk upgrades without sending technicians on-site.

Configure your system to use derived alarms and controls. By combining multiple events into critical alarms, you automate local or centralized responses. Integrate control relays with the correct specifications for remote device switching. You should also enable ping alarms to detect communication failures early. Local pinging through RTUs reduces unnecessary network traffic.

When installing equipment, consider the site climate. Choose rugged devices that withstand extreme temperatures and humidity. Support multiple transport options—LAN, dial-up, or T1—to leverage your existing network and allow gradual upgrades. For legacy systems, use serial reach-through ports to access older devices remotely.

💡 Tip: Always verify that your equipment meets regulatory certifications such as FCC, NEBS, and RoHS for safety and compliance.

Best Practices

To ensure reliable operation, you should adopt several best practices:

Monitor temperature at multiple rack locations—top, middle, and bottom—using ASHRAE guidelines.

Track humidity levels to prevent electrostatic discharge and condensation.

Use vibration sensors to detect shocks or seismic activity.

Deploy dust and particle sensors to identify harmful airborne contaminants.

Place water and leak sensors near cooling units and room perimeters.

Implement access and security sensors to monitor physical entry.

You should also provide comprehensive training for your O&M teams. Safety training must cover high-voltage handling, PPE, and emergency response. Equipment-specific instruction helps your team understand system functions and troubleshooting. Documentation training ensures accurate records for compliance and future reference.

Smart Hands services can further support your operations. These professionals handle on-site tasks such as hardware installation, cabling, and guided maintenance. By combining remote monitoring with skilled on-site support, you maximize uptime and operational efficiency.

🚀 Note: Integrating smart alerts and remote control with robust training and environmental monitoring creates a resilient, future-ready telecom network.

You can achieve measurable O&M cost savings by adopting smart alerts and remote control in your Telecom Cabinet Power Controller. These features help you respond faster, reduce site visits, and improve network reliability. You gain a competitive edge in the telecom industry. Start evaluating your current systems and consider upgrading to solutions that support these advanced capabilities. Take the next step to optimize your operations and lower your expenses.

FAQ

What types of alerts can you receive from a Telecom Cabinet Power Controller?

You receive alerts for power failures, temperature spikes, battery health issues, and unauthorized access. The system sends notifications by email, SMS, or app. You can customize alert thresholds to match your network’s needs.

How do remote diagnostics reduce maintenance costs?

Remote diagnostics let you monitor equipment health and troubleshoot issues without sending technicians on-site. You save on travel, labor, and downtime. You also schedule maintenance only when needed, which extends equipment life.

Can you integrate these controllers with existing network management systems?

Yes, you can integrate most controllers using open protocols like SNMP or Modbus. This allows you to manage alarms and data from a single dashboard. You avoid vendor lock-in and streamline your operations.

Are smart alerts and remote control features secure?

You benefit from advanced security features. The system uses encrypted communication, access controls, and regular software updates. You protect your network from unauthorized access and cyber threats.

What training do your teams need to operate these systems?

You should provide training on system functions, safety procedures, and troubleshooting. Teams learn to use dashboards, respond to alerts, and follow compliance guidelines. Ongoing education ensures your staff stays updated on new features.

See Also

Smart Microgrid Energy Storage Solutions For Telecom Cabinets

Understanding The ESTEL Power System For Telecom Cabinets

Strategies To Guarantee Consistent Power For Telecom Cabinets

Best Practices For Effective Monitoring Of Outdoor Telecom Cabinets

Solar Powered Energy Storage Systems Designed For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA