A Closer Look at ESTEL Telecom Cabinet Sensor Features

Telecom cabinet sensors deliver immediate value for telecom cabinets by combining advanced features that monitor conditions, secure telecom enclosures, and support operational efficiency. These features help prevent downtime and ensure optimal performance in telecom cabinets. Protecting equipment becomes easier with real-time monitoring and threshold alerts. The sensors also offer critical insights for telecom enclosures, as industry research shows that balanced power distribution improves operational performance by 25%.

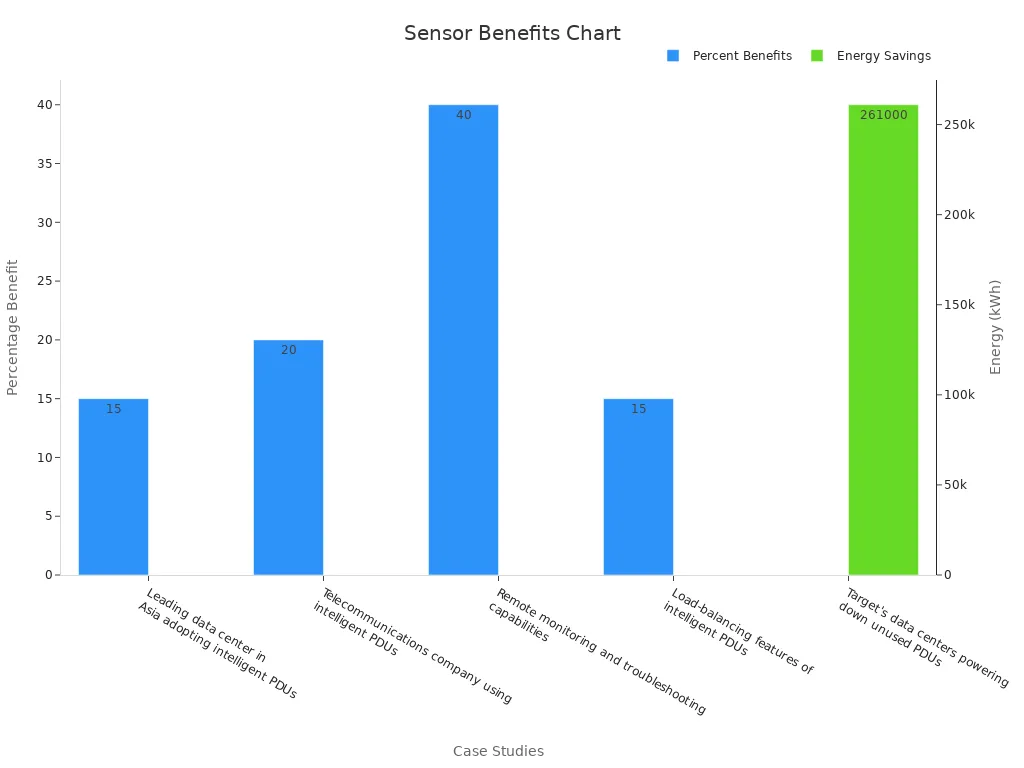

Outcome / Numerical Benefit | |

|---|---|

Leading data center in Asia adopting intelligent PDUs | 15% reduction in energy consumption, lowering operational costs |

Telecommunications company using intelligent PDUs | 20% improvement in equipment uptime and significant maintenance cost reduction |

Target's data centers powering down unused PDUs | Annual energy savings of 261,000 kWh |

Remote monitoring and troubleshooting capabilities | 40% improvement in maintenance response times |

Load-balancing features of intelligent PDUs | 15% reduction in unintentional power outages |

Telecom cabinet sensors in telecom enclosures provide real-time monitoring and proactive issue resolution.

These features reduce downtime and increase energy efficiency across telecom cabinets.

Key Takeaways

ESTEL telecom cabinet sensors provide real-time monitoring of temperature, humidity, airflow, and security to protect equipment and prevent downtime.

Threshold alerts and remote monitoring enable quick responses to environmental changes and security threats, improving network uptime and reducing maintenance costs.

Advanced sensors like D-Wire and thermal mapping help detect hot spots, airflow issues, and equipment health problems early, supporting proactive maintenance.

Power independence and backup systems keep sensors operational during outages, ensuring continuous protection and reliable monitoring.

Energy-efficient features and intelligent management reduce power consumption, lower operational costs, and support sustainability goals for telecom operators.

Telecom Cabinet Sensors

Temperature and Humidity

Telecom cabinet sensors play a vital role in maintaining the right environment inside telecom cabinets. Temperature and humidity sensors help prevent equipment overheating and ensure optimal operating conditions. These sensors measure the air near server rack cabinet inlets, where temperature can fluctuate quickly. Maintaining temperature between 64.4°F and 80.6°F (18-27°C) and humidity between 40% and 60% helps protect sensitive electronics.

Tip: Place multiple sensors per server rack cabinet, especially near air intake vents, to achieve precise environment monitoring.

Parameter | Recommended Range | Allowable Range (NEBS/TC9.9) |

|---|---|---|

Temperature (Air Inlet) | 64.4°F – 80.6°F (18-27°C) | 41°F – 104°F (5-40°C) |

Relative Humidity (RH) | 40% – 60% (ASHRAE) | 5% – 85% (NEBS allowable) |

Humidity Notes | Recommended ~50% RH | Low humidity allowed down to 8% RH (post-2016 update) |

High-quality sensors ensure accuracy and rapid detection of environmental changes. Monitoring temperature and humidity in real time allows operators to respond quickly to any deviations. This approach reduces the risk of equipment failure and supports continuous operation in telecom cabinets.

D-Wire Sensors

D-Wire sensors offer advanced monitoring for server rack cabinet environments. These sensors can be daisy-chained, allowing one cable to connect multiple sensors across several cabinets. D-Wire sensors track voltage, temperature, and internal resistance in battery cells. This data helps operators assess equipment health and prevent failures before they occur.

D-Wire sensors provide detailed insights into the thermal and electrical status of each server rack cabinet.

Operators can monitor temperature differential across battery cells, identifying potential hot spots or imbalances.

The daisy-chain design simplifies installation and reduces cable clutter inside telecom cabinets.

D-Wire sensors support environment monitoring by delivering accurate, real-time data. This information enables proactive maintenance and extends the lifespan of critical equipment.

Threshold Alerts

Threshold alerts form a core feature of telecom cabinet sensors. These alerts trigger when temperature or humidity moves outside recommended ranges. For example, a tier-one early warning alert activates if humidity drops below 40% or rises above 60%. A tier-two critical alert triggers if humidity falls below 30% or exceeds 70%. These alerts help operators act before minor issues become major problems.

Threshold alerts use high-accuracy sensors to detect changes instantly.

Operators receive notifications through remote monitoring systems, allowing for immediate response.

Strategic placement of sensors in each server rack cabinet ensures no area goes unmonitored.

Threshold alerts support both operational efficiency and equipment protection. By responding to alerts quickly, operators can maintain stable conditions and avoid costly downtime in telecom cabinets.

Security and Access

Motion Sensors

Motion sensors help telecom operators detect unauthorized activity around or inside cabinets. These devices sense movement and trigger alerts when someone enters a restricted area. Operators can set up these sensors to monitor both the interior and exterior of telecom enclosures. When motion occurs, the system sends a notification to security personnel. This quick response helps prevent theft and tampering.

Operators often use motion sensors as part of a layered approach to security. These devices work well with other security features to create a strong defense.

Door and Intrusion Detection

Door and intrusion detection systems monitor access points on telecom cabinets. Each sensor tracks when a door opens or closes. If someone tries to force entry or leaves a door open, the system records the event and sends an alert. This process helps operators maintain strict control over who accesses sensitive equipment.

Door sensors can log every access event.

Intrusion detection systems can trigger alarms or lock down cabinets automatically.

These tools support securing against vandalism and unauthorized access.

Operators rely on these systems to protect valuable assets and ensure only authorized personnel enter telecom cabinets.

Tilt & Shock Sensors

Tilt and shock sensors play a key role in monitoring the physical condition of telecom cabinets. These devices detect sudden movements, impacts, or changes in orientation. If someone tries to move or tamper with a cabinet, the sensor triggers an immediate alert. Recent systematic reviews show that multi-sensor systems, including accelerometers and gyroscopes, deliver reliable and accurate movement monitoring. Studies report mean validity scores of 87%, with some reaching up to 96%. Research also demonstrates that tilt sensors can track real-time changes in angle and displacement, making them effective for early warning and equipment protection.

These sensors help operators respond quickly to physical threats. They also support maintenance teams by identifying accidental bumps or shocks that could damage equipment. By using tilt and shock sensors, telecom operators add another layer of protection to their security features.

Thermal Mapping and Airflow

Cabinet Analysis Sensor

The cabinet analysis sensor provides a foundation for advanced climate control in telecom cabinets. This sensor measures temperature at multiple points, including the front, rear, top, middle, and bottom of the cabinet. It also tracks humidity and differential pressure. Operators use this data to create a cabinet thermal map, which visualizes temperature gradients and airflow patterns. The sensor calculates the front-to-rear temperature differential (△T) and displays it with animated arrows in rack map views. This approach helps identify areas with poor ventilation and cooling.

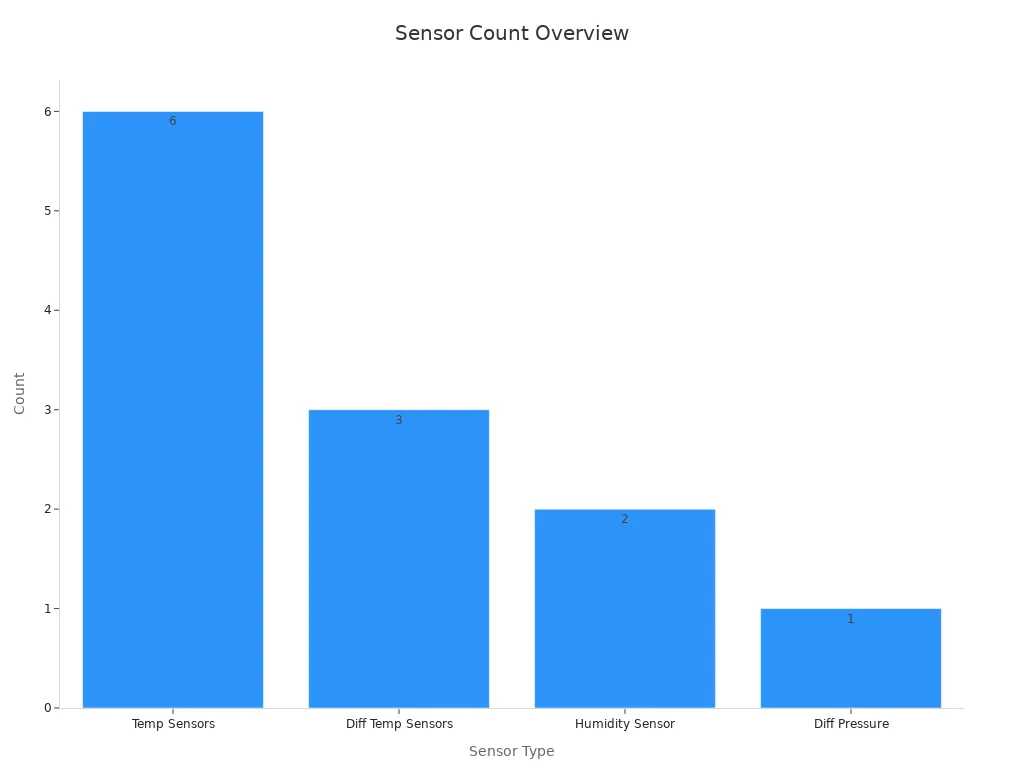

Feature | Details |

|---|---|

Number of Temperature Sensors | 6 temperature sensors + 3 differential temperature sensors |

Temperature Measurement Range | -40°C to +75°C |

Temperature Resolution | 0.1°C increments |

Temperature Accuracy | ±0.3°C at key points (-40°C, +25°C, +75°C) |

Thermal Mapping Capability | Front-to-rear temperature differential (△T) calculated and visualized with animated arrows in AKCPro Server rack maps |

Additional Sensors | Humidity (2 sensors), Differential Pressure (1 sensor) |

Purpose | Enables detailed temperature distribution monitoring, hotspot detection, and airflow analysis in telecom cabinets |

Airflow Monitoring

Accurate airflow monitoring is essential for effective thermal management. The cabinet analysis sensor uses differential pressure sensors to measure airflow changes with an accuracy of ±3%. Operators place sensor tubes in high and low pressure zones, such as inside and outside racks or under raised floors. This setup detects leaks, obstructions, and validates improvements in ventilation. Real-time data from these sensors integrates with building management systems, supporting hot/cold aisle containment strategies. Modeling shows that a 1°C error in temperature measurement can increase energy consumption by up to 9%. Reliable airflow monitoring reduces energy waste and supports long-term equipment health.

Differential pressure sensors provide continuous feedback on airflow efficiency.

AI tools analyze sensor data to automate cooling adjustments.

Proper ventilation and cooling lower cumulative thermal resistance by up to 60%, improving overall system reliability.

Hot Spot Detection

Hot spot detection protects equipment from overheating and fire risks. The cabinet analysis sensor identifies abnormal temperature rises between 80°C and 130°C, allowing early intervention. Early detection prevents equipment failure and costly downtime. Statistics show that 25% of building fires result from electrical malfunctions, with annual damages reaching $3.2 billion in the U.S. and Europe. By monitoring for hot spots, operators can address issues months before they become critical. This proactive approach ensures safe operation and extends equipment lifespan.

Reliability in Telecom Cabinets

Remote Monitoring

Remote monitoring systems give operators real-time visibility into telecom cabinets and server rack cabinet environments. These systems collect data from temperature, humidity, and differential pressure sensors. Operators can track environmental changes, equipment status, and security events from any location. This approach reduces the need for on-site checks and speeds up response times. Remote monitoring also supports scalability, allowing operators to manage multiple telecom enclosures and server rack cabinet installations at once. With continuous data collection, teams can identify trends and address issues before they affect network performance.

Smoke and Water Sensors

Smoke and water sensors play a critical role in protecting telecom cabinets and server rack cabinet equipment. Smoke sensors provide early warnings of fire hazards, enabling rapid intervention to prevent damage. Air Sampling Smoke Detection systems detect microscopic smoke particles before visible smoke appears. These systems often identify overheating wires in telecom enclosures, allowing staff to act before a fire starts. Water leak sensors use conductive ropes, smart cables, and spot sensors to detect leaks from HVAC or fire system piping. When water appears near a server rack cabinet, the sensor triggers an alert for immediate action. Placing these sensors under racks and near equipment ensures early detection and helps prevent costly downtime. Together, smoke and water sensors enhance safety and reliability in telecom cabinets and telecom enclosures.

Power Independence

Power independence ensures that monitoring systems in telecom cabinets and server rack cabinet installations remain operational during outages. Research shows that distributed energy resources and microgrids improve system reliability by providing localized power. These systems supply critical loads, such as sensors, even when the main grid fails. Energy storage solutions help manage sudden load changes and maintain stable operation. Reliable power sources allow differential pressure, temperature, and other sensors to function continuously. This independence reduces the risk of losing monitoring capabilities during emergencies. Power independence supports the overall reliability and safety of telecom enclosures, especially when monitoring pressure and differential pressure is essential for equipment protection.

Benefits

Equipment Protection

Telecom operators rely on advanced features to keep their assets safe. Sensors in telecom cabinets and telecom enclosures detect temperature spikes, humidity changes, smoke, and water leaks. These features help operators act before small issues become major failures. IoT technology enables real-time monitoring and predictive maintenance, which improves equipment protection by detecting anomalies early and scheduling just-in-time maintenance. Operators use these features to prevent overheating, electrical faults, and physical tampering. By protecting equipment, telecom companies avoid costly repairs and extend the lifespan of their infrastructure.

Network Uptime

Maintaining high network uptime is essential for telecom operators. The features built into ESTEL sensor solutions support continuous operation in telecom cabinets and telecom enclosures. Operators benefit from real-time alerts, remote monitoring, and predictive analytics. These tools help identify risks and resolve issues before they cause outages.

80% of recent outages were preventable through proactive measures enabled by ESTEL PDUs.

Power outages are the primary cause of downtime for 33% of survey respondents.

Real-time environmental monitoring detects risks early and prevents failures.

AI-driven predictive analytics anticipate failures weeks in advance, reducing unexpected disruptions.

Hot-swappable components and remote monitoring allow maintenance without shutdown, minimizing downtime.

Operators use these features to maximize uptime and deliver reliable service to customers.

Energy Efficiency

Energy efficiency remains a top priority for telecom operators. Features such as intelligent monitoring and automated energy management optimize power use in telecom cabinets. Power Usage Effectiveness (PUE) and Energy Savings Rate (ESR) serve as key metrics for comparing cooling technologies. Advanced cooling systems, like immersion liquid cooling, show lower PUE and higher ESR, which means better energy efficiency and cost savings. A novel ventilation system combining chimney ventilation and air conditioning in telecom base stations achieved over 50% reduction in air conditioner power consumption. These features help operators reduce waste, lower operational costs, and support sustainability goals.

Note: Granular energy consumption data from sensors helps maintain higher system efficiency and supports regulatory compliance.

ESTEL telecom cabinet sensors deliver comprehensive protection, reliability, and performance for telecom operators. Sensor-integrated cabinets outperform traditional systems in several ways:

Operators gain remote, wireless real-time monitoring of temperature, airflow, and battery health.

IoT sensors reduce on-site visits and operational costs.

Wireless deployment enables broader data collection and easier installation.

Predictive maintenance and self-healing infrastructure become possible.

Thermoelectric cooling systems with integrated sensors also improve energy efficiency and lower environmental impact. These features help operators optimize resources and extend equipment life. Telecom operators should consider evaluating ESTEL sensor solutions to achieve greater operational efficiency and cost savings.

FAQ

What types of sensors does ESTEL offer for telecom cabinets?

ESTEL provides temperature, humidity, D-Wire, motion, door, tilt, shock, smoke, water, and airflow sensors. These devices help monitor environmental and security conditions inside telecom cabinets.

How do threshold alerts improve equipment safety?

Threshold alerts notify operators when temperature or humidity moves outside safe ranges. This early warning system helps prevent equipment damage and reduces the risk of costly downtime.

Can operators monitor telecom cabinets remotely?

Yes. Operators use remote monitoring systems to track sensor data in real time. This feature allows quick response to issues and reduces the need for on-site visits.

Why is airflow monitoring important in telecom cabinets?

Proper airflow prevents overheating and improves cooling efficiency. Airflow sensors detect blockages or leaks, helping operators maintain optimal conditions and extend equipment life.

Do ESTEL sensors work during power outages?

ESTEL sensors support power independence. Backup power sources keep sensors running during outages, ensuring continuous monitoring and protection for telecom equipment.

See Also

Exploring The Design Of ESTEL Outdoor Telecom Cabinets

An Overview Of ESTEL Telecom Cabinet Power Systems

Safety Features In Custom ESTEL Outdoor Telecom Cabinets

Key Structural Design Standards For ESTEL Telecom Cabinets

Essential Design Criteria For ESTEL Outdoor Base Station Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA