Expert Advice on Telecom Enclosure Maintenance

Taking care of telecom enclosures in tough places is important. Ignoring upkeep can cause equipment to break and more downtime. This can upset customers. Checking regularly and fixing things early prevents sudden problems. Planning maintenance and having spare parts ready helps fix issues fast. This saves money on emergency repairs and makes equipment last longer. By solving problems early, your systems stay reliable and work well.

Key Takeaways

Taking care of telecom enclosures stops big repairs and delays. Plan checks and cleanings to find problems early.

Use tough materials and waterproof coatings to shield enclosures. This makes them last longer and saves money on fixes.

Add remote monitoring tools to get live updates on enclosures. This helps you act fast if something goes wrong.

Teach workers the right way to do maintenance. A trained team keeps everything working well.

Make seasonal checklists to handle different problems during the year. This smart plan keeps equipment safe and working well.

Challenges Faced by Telecom Enclosures in Harsh Environments

Weather-related threats to telecom enclosures

Bad weather can harm telecom enclosures and make them weaker. Ice and snow can break towers or power lines. Freezing and thawing can crack foundations, making them unsafe. Cold weather also scatters signals, making them weaker and slower. Batteries lose power faster in freezing temperatures, causing equipment to fail. Keeping enclosures working in cold weather is harder. Heating uses more energy, and repairs take longer in the cold.

Dust and debris infiltration risks

Dust and dirt can damage telecom enclosures, especially in dry areas. When dust gets inside, it blocks vents and overheats equipment. This lowers how well the equipment works. Dust on parts can cause short circuits or ruin them. You can stop this by sealing and cleaning the enclosure often. Keeping dust out helps the equipment last longer and work better.

Physical damage and vandalism concerns

Telecom enclosures can get damaged by accidents, storms, or vandalism. Falling branches or car crashes can crack or dent them. This lets water or dirt get inside and harm the parts. Vandalism, like graffiti or tampering, can also break the enclosure and stop service. Using strong materials and locks can protect the enclosure. Checking for damage often helps fix problems early.

Corrosion and rust from moisture exposure

Moisture is a major problem for telecom enclosures. When water or humidity gets inside, it can cause rust. Rust weakens metal parts and damages the structure. Over time, this can break equipment and stop it from working. Fixing these problems can be expensive and cause service delays.

To avoid this, check your enclosures often. Look at seals and gaskets to make sure they are not broken. These parts block water from getting inside. If they are cracked or worn out, replace them quickly. This keeps your enclosure safe from moisture.

In humid areas, rust is an even bigger issue. Anti-rust coatings can help protect the enclosure. These coatings stop rust and shield parts from chemical damage. Adding them to enclosures and parts can make them last longer.

Skipping maintenance makes problems worse. Rust and water damage can lead to costly repairs. It can also cause equipment to stop working. Regular care keeps your equipment running well, even in tough conditions.

Here’s a simple table showing how moisture affects telecom enclosures and what you can do:

Issue | Impact | Solution |

|---|---|---|

Water getting inside | Causes rust and damages internal parts | Check and fix seals and gaskets regularly |

High humidity | Makes rust and chemical damage worse | Use anti-rust coatings for extra protection |

Skipping maintenance | Leads to broken parts and higher repair costs | Do regular maintenance to catch problems early |

By taking care of moisture issues, you can protect your telecom enclosures and keep them working without interruptions.

Routine Maintenance Practices for Telecom Enclosures

Cleaning and debris removal

Keeping telecom enclosures clean helps them work better. Dust and dirt can block vents and overheat equipment. Cleaning often stops these problems and keeps things running smoothly.

A good way to clean is by using water-based systems. These systems wash and rinse in a loop, cutting waste and saving energy. Some systems even reuse water, which is better for the environment. Using these methods keeps enclosures clean and saves resources.

Make cleaning a habit. Clear vents, wipe surfaces, and check for dirt inside. A clean enclosure lasts longer and avoids sudden breakdowns.

Regular inspections for wear and damage

Checking your telecom enclosure often helps find problems early. Parts can wear out from weather or regular use. Fixing issues early avoids expensive repairs later.

New tools like drones and smart tech make inspections easier. Drones take pictures and create 3D models to check the enclosure. Digital twins give a virtual copy to spot problems faster. These tools save time and make inspections more accurate.

When inspecting, check seals, gaskets, and structure for cracks or rust. Write down what you find and fix important issues first. This keeps your enclosure in good condition.

Addressing minor issues promptly

Small problems can grow into big ones if ignored. Fixing them quickly keeps your telecom enclosure working well.

For example, a tiny crack in a seal might not seem serious. But it can let water in, causing rust and damage. Replacing the seal right away costs less than fixing water damage later.

Fixing problems early saves money and avoids downtime. Preventative care is cheaper than waiting for things to break. It also makes equipment last longer, saving more money over time.

By staying alert and fixing small issues fast, you keep your telecom enclosure reliable and efficient.

Ensuring proper sealing and gasket maintenance

Taking care of seals and gaskets is very important. They protect your telecom enclosure from water, dust, and dirt. If seals or gaskets fail, equipment can get damaged. This leads to expensive repairs and downtime. Regular checks keep them working well and make enclosures last longer.

Why Sealing and Gasket Maintenance Matters

Seals and gaskets block water and dust from getting inside. This lowers the chance of rust and equipment breaking.

Good sealants create a strong barrier to protect parts inside.

Checking seals often helps find problems before they get worse.

A study showed how GORE® Protective Vents help seals last longer. These vents balance pressure inside the enclosure. This reduces stress on seals and stops them from failing early. They also keep water and dust out, making outdoor enclosures last longer.

Best Practices for Maintaining Seals and Gaskets

Inspect Seals Regularly

Look at seals and gaskets for cracks or damage. Broken seals let water and dirt in. Replace damaged parts quickly to keep them working well.Clean Seals and Gaskets

Dirt can build up on seals and make them less effective. Use a soft cloth and gentle cleaner to wipe them. Don’t use strong chemicals that might harm the material.Apply Protective Coatings

Anti-rust coatings make seals and gaskets stronger. These coatings protect against water and chemicals, especially in wet areas.Use Durable Sealing Technologies

Choose strong sealing products made for outdoor use. They stop water from getting in and protect your enclosure from damage.

Key Findings on Sealing Effectiveness

Evidence | Description |

|---|---|

Sealing Technologies | Strong sealing products stop water from getting inside. |

GORE® Protective Vents | These vents reduce seal stress and help enclosures last longer. |

By following these tips, you can keep your telecom enclosure safe and working well. Taking care of seals and gaskets saves money and avoids big problems later.

Tip: Check seals during each season and replace them if needed. This helps prevent sudden failures.

Managing Extreme Weather Conditions for Telecom Enclosures

Climate control solutions for temperature regulation

Extreme weather can harm telecom equipment. Hot weather may cause overheating. Freezing temperatures can make equipment stop working. To keep equipment safe, use good climate control systems.

Advanced Cooling Systems: Liquid coolers and thermoelectric systems keep temperatures steady. These are great for sensitive equipment that needs stable conditions.

Smart Temperature Control Systems: Modern systems use thermostats and IoT to adjust temperatures. They heat or cool automatically when needed.

Insulated Panels: Insulation in walls keeps the inside temperature steady. This reduces the work of cooling systems and saves energy.

These solutions protect equipment from extreme temperatures and help it last longer.

Tip: Check the enclosure’s temperature often. Catching changes early can stop costly problems.

Securing connections to prevent water ingress

Water getting inside is a big problem for telecom enclosures. Rain or snow can damage equipment. Securing connections keeps water out and protects your system.

Use gaskets to seal where surfaces meet. This blocks water from entering.

Apply RTV silicone as extra protection. Make sure it’s applied correctly to avoid gaps.

Install cord grips and sealed connectors to protect wires. These stop water and dirt from getting in.

Place hinges outside of gaskets to keep seals strong.

Use braided loom on wires to let water flow out instead of staying trapped.

Leave small gaps between conduits and connectors. This helps water escape and prevents pooling.

Enclosures made of aluminum or stainless steel resist rust and bad weather. They keep equipment safe and working well.

Note: Check seals and connectors after storms. Fixing issues quickly stops bigger problems later.

Ventilation and airflow management

Good airflow is important to manage heat from telecom equipment. Without it, equipment can overheat and fail.

Advanced Cooling Systems: These systems work with vents to remove heat.

Intelligent Cooling Technologies: These adjust airflow based on the temperature inside. They save energy and help equipment last longer.

Dust Filters: Filters on vents stop dust and dirt from getting inside. This keeps the equipment clean and prevents overheating.

Strategic Vent Placement: Place vents where they can spread air evenly and cool the enclosure.

Outdoor telecom cabinets are built to handle tough weather. They have vents that protect equipment from heat and dirt.

Tip: Clean vent filters often. Dirty filters block airflow and waste energy.

Weatherproof materials and coatings for protection

Weatherproof materials and coatings help protect telecom enclosures from bad weather. They shield equipment from rain, snow, sunlight, and other harmful elements. Picking the right materials keeps enclosures strong and working for a long time.

Benefits of Weatherproof Materials

Enhanced Durability

Materials like stainless steel and aluminum resist rust and corrosion. They stay strong even in wet or coastal areas.UV Protection

Special coatings block sunlight, stopping cracks and fading. This keeps equipment safe and lasts longer.Moisture Resistance

Weatherproof coatings stop water from getting inside. This prevents rust and damage to the equipment.Temperature Stability

Fiberglass-reinforced plastic handles hot and cold weather without breaking. It keeps equipment safe in extreme climates.

Types of Weatherproof Coatings

Powder Coatings

These coatings make a tough layer that resists scratches and rust. They are great for outdoor use.Epoxy Coatings

Epoxy coatings block water and chemicals. They protect the enclosure from moisture damage.Polyurethane Coatings

These coatings are flexible and protect against sunlight. They work well in sunny areas.

Tip: Use coatings made for outdoor use. They give the best protection from weather damage.

Real-World Testing for Durability

Manufacturers test materials and coatings in tough conditions. These tests mimic bad weather, temperature changes, and stress. Only the strongest materials pass. This ensures your enclosures can handle real-world challenges.

Comparison of Common Weatherproof Materials

Material | Strengths | Best Use |

|---|---|---|

Stainless Steel | Rust-resistant, very strong | Wet or coastal areas |

Aluminum | Lightweight, resists rust | General outdoor use |

Fiberglass-Reinforced Plastic | Handles extreme heat or cold, non-conductive | Hot or freezing places |

Using weatherproof materials and coatings protects telecom enclosures from damage. This lowers repair costs and keeps systems running smoothly.

Note: Check enclosures often for worn coatings. Reapply coatings when needed to keep them protective.

Preventative Measures to Protect Telecom Enclosures

Seasonal maintenance checklists

Each season brings different challenges for telecom enclosures. A checklist helps you fix problems early.

Spring: Look for winter damage like cracks in seals. Clean vents and remove any debris.

Summer: Check cooling systems to stop overheating. Make sure vents work well. Look for UV damage on coatings.

Fall: Remove leaves and dirt near the enclosure. Check for pests that may have made nests.

Winter: Test heating systems to ensure they work. Remove ice from doors and seals. Secure all connections to keep water out.

Using a seasonal checklist keeps your equipment safe all year.

Corrosion-resistant materials and coatings

Corrosion can ruin telecom enclosures and cost a lot to fix. Using materials that resist corrosion saves money over time.

Corrosion costs the U.S. over $276 billion yearly. Indirect costs make it even higher.

Fiberglass-reinforced plastic (FRP) resists corrosion better than metal. It also needs less upkeep, so no frequent painting is required.

Choosing corrosion-resistant materials lowers repair costs and makes enclosures last longer. Coatings like epoxy or powder coatings add extra protection from water and chemicals. These options keep enclosures strong in tough conditions.

Surge protection for electrical components

Power surges can harm the equipment inside telecom enclosures. Surge protection devices (SPDs) help prevent this.

SPDs stop damage from power surges, cutting repair costs.

They improve network reliability, reducing outages and keeping customers happy.

SPDs make equipment last longer, lowering replacement costs.

Adding surge protection is a small cost with big benefits. It protects your equipment, keeps services running, and saves money over time.

Making enclosures stronger to avoid physical damage

Telecom enclosures can be harmed by accidents, vandalism, or nature. Strengthening them keeps your equipment safe and working well. Here are simple ways to protect your enclosures:

Pick strong materials: Use enclosures made of stainless steel or fiberglass. These materials handle impacts and last longer in tough places.

Add protective barriers: Set up fences, bollards, or concrete walls around enclosures. These stop damage from cars or falling objects.

Use tamper-proof designs: Add locks, hidden fasteners, and strong hinges to enclosures. These features make it harder for vandals to break in.

Apply tough coatings: Coatings like epoxy or polyurethane protect against cracks and dents. They also absorb shocks to keep enclosures safe.

Tip: Check barriers and locks often to ensure they work. Replace broken parts quickly.

Comparing Strong Materials

Material | Benefits | Best Places to Use |

|---|---|---|

Stainless Steel | Resists impacts, doesn’t rust | Cities or factories |

Reinforced Fiberglass | Light, non-conductive | Remote or risky areas |

Polycarbonate | Doesn’t shatter, blocks UV rays | Vandal-prone locations |

You can also use shock-absorbing mounts. These mounts reduce shaking and protect delicate equipment inside the enclosure.

By making enclosures stronger, you avoid expensive repairs and downtime. Strong enclosures protect your telecom systems and give you peace of mind.

Note: Check the risks in your area before choosing protection. Custom solutions work best for long-term safety.

Standardizing Maintenance Processes for Telecom Enclosures

Creating regular maintenance schedules

Making a regular maintenance schedule keeps your telecom enclosure in good shape. Routine care stops small problems from becoming expensive repairs. Focus on key parts like seals, gaskets, and cooling systems. Set specific times for inspections, cleaning, and replacing parts.

A clear schedule also helps you prepare for seasonal changes. For instance, check cooling systems in summer and heating systems in winter. Following a routine avoids sudden breakdowns and helps your equipment last longer.

Tip: Use a digital planner or software to track tasks and set reminders for checks.

Using remote monitoring tools

Remote monitoring tools change how you care for telecom enclosures. They give live updates on system health, helping you fix problems early. IoT-enabled tools track conditions and send alerts when something is wrong.

Here’s how remote monitoring helps maintenance:

Live tracking: Spots problems quickly, stopping equipment failures.

Fixing remotely: Solves many issues without needing to visit the site.

Risk prediction: Finds risks early, making equipment last longer.

Alert systems: Helps teams focus on the most urgent problems first.

Feature | Benefit |

|---|---|

Live tracking | Quickly finds issues, avoiding costly failures and service interruptions. |

Fixing remotely | Lets technicians solve problems faster without traveling to the site. |

Risk prediction | Stops failures before they happen, extending equipment life. |

Alert systems | Helps teams respond to serious issues first, saving time and resources. |

Using these tools reduces downtime and makes your operations more efficient.

Teaching staff proper methods

Your team is key to keeping telecom enclosures working well. Training them on proper methods ensures they can handle tasks correctly. Teach them to check seals, clean vents, and use monitoring tools.

Hands-on training and online lessons help staff learn new skills. Encourage them to write down their work to improve tracking and accountability. A skilled team avoids mistakes and keeps systems running smoothly.

Note: Update training programs often to match new industry tools and practices.

Writing Down Maintenance Work for Better Tracking

Keeping records of maintenance work helps track tasks and improves how well your telecom enclosures work. It shows what has been done, spots repeated problems, and helps plan future fixes.

Why Keeping Records is Important

Makes Things Clear

Writing down tasks shows what has been done. It helps check if the team is doing their job and ensures no steps are skipped.Easier Problem Solving

Logs help find patterns when issues happen. This makes fixing problems faster and simpler.Follows Rules

Some industries need proof of regular maintenance. Good records help meet these rules and keep things safe.

Tips for Keeping Maintenance Records

Use Simple Forms

Make a form to write down tasks. Include spaces for dates, jobs done, parts changed, and who did the work. This keeps records neat and easy to read.Try Digital Tools

Use apps or software to save records. You can add photos, set reminders, and check logs from anywhere.Sort by Date and Equipment

Keep records in order by date and type of enclosure. This makes finding details quick and easy.

Sample Maintenance Log

Date | Task Done | Parts Changed | Worker | Notes |

|---|---|---|---|---|

10/15/2023 | Cleaned vents, checked seals | None | John Doe | No problems found |

10/20/2023 | Replaced gasket | Gasket #1234 | Jane Smith | Small wear noticed |

Tip: Check your logs every month. Look for patterns and update your maintenance plans if needed.

By keeping good records, you make sure your telecom enclosures stay in great shape. This saves time, cuts costs, and keeps your operations running smoothly.

Taking care of your telecom enclosure helps it work well. Regular tasks like cleaning and checking seals stop small problems from growing. Using strong materials and coatings protects equipment from weather and makes it last longer. Clear plans make maintenance easier and faster.

By 2025, industries will hold 38.6% of the market, showing the importance of good maintenance.

Manufacturing enclosures make up 47.3% of the market, stressing the need for easy upkeep.

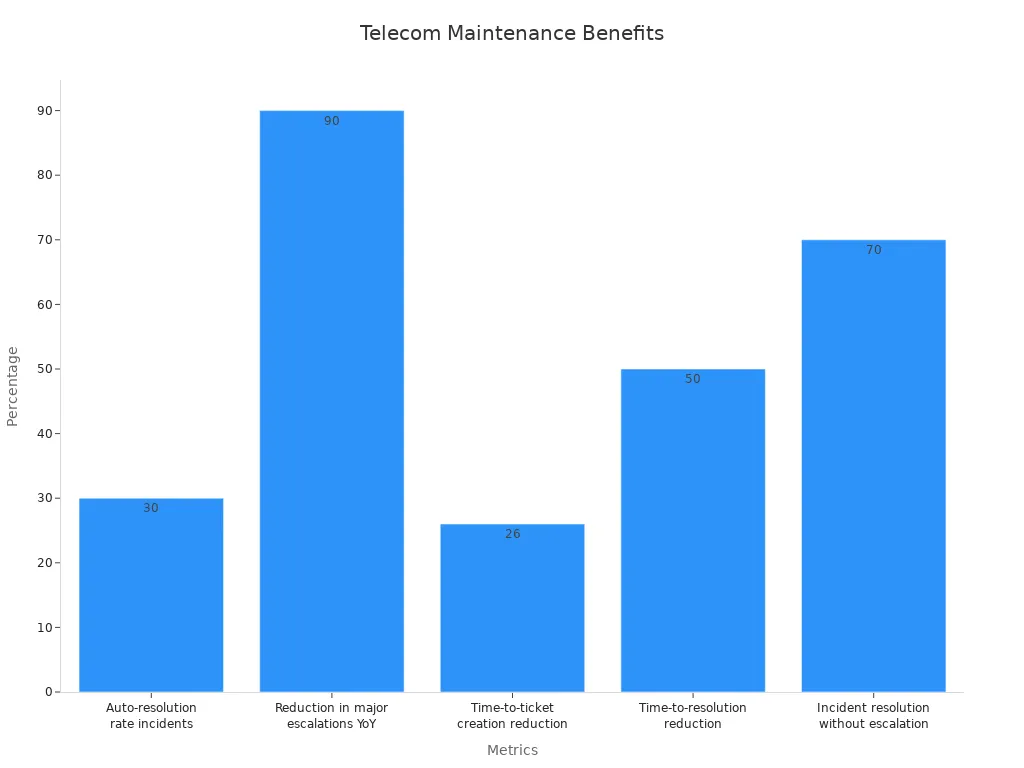

Taking early action brings clear benefits:

Measure | Improvement |

|---|---|

Problems fixed automatically | 30% |

Fewer big issues each year | 90% |

Faster problem-solving | 50% |

By following these steps, you keep your equipment reliable and efficient for years.

FAQ

What’s the easiest way to clean a telecom enclosure?

Use a soft cloth with mild soap to clean surfaces. Stay away from strong cleaners that might harm the material. For vents, use a vacuum or air blower to clear dust. Cleaning often stops overheating and helps your equipment last longer.

How often should telecom enclosures be checked?

Check enclosures every three months for damage or wear. Look for cracks, rust, or broken seals. During seasonal changes, inspect more often. Regular checks catch problems early and save on repairs.

What materials work best for outdoor telecom enclosures?

Stainless steel and fiberglass-reinforced plastic are great choices. Stainless steel fights rust, and fiberglass handles extreme weather. Both materials are strong and protect equipment from bad conditions.

How d

o you stop water from getting into enclosures?

Make sure seals and gaskets are in good shape. Add RTV silicone for extra sealing. Use cord grips and sealed connectors to block water. Check these parts often, especially after storms, to keep water out.

Why is surge protection needed for telecom enclosures?

Power surges can harm delicate equipment. Surge protection devices (SPDs) absorb extra voltage to stop damage. They make systems more reliable, reduce downtime, and help equipment last longer. SPDs are a smart and affordable way to protect your system.

Tip: Keep a record of cleaning, checks, and repairs. This helps you take care of your telecom enclosures regularly.

See Also

Essential Advice for Caring for Outdoor Telecom Cabinets

Safeguarding Outdoor Telecom Cabinets Through Effective Maintenance

Ways to Shield Equipment Using Outdoor Telecom Cabinets

Requirements for Ensuring Longevity of Outdoor Telecom Cabinets

Tips for Maintaining Ideal Temperature in Outdoor Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA