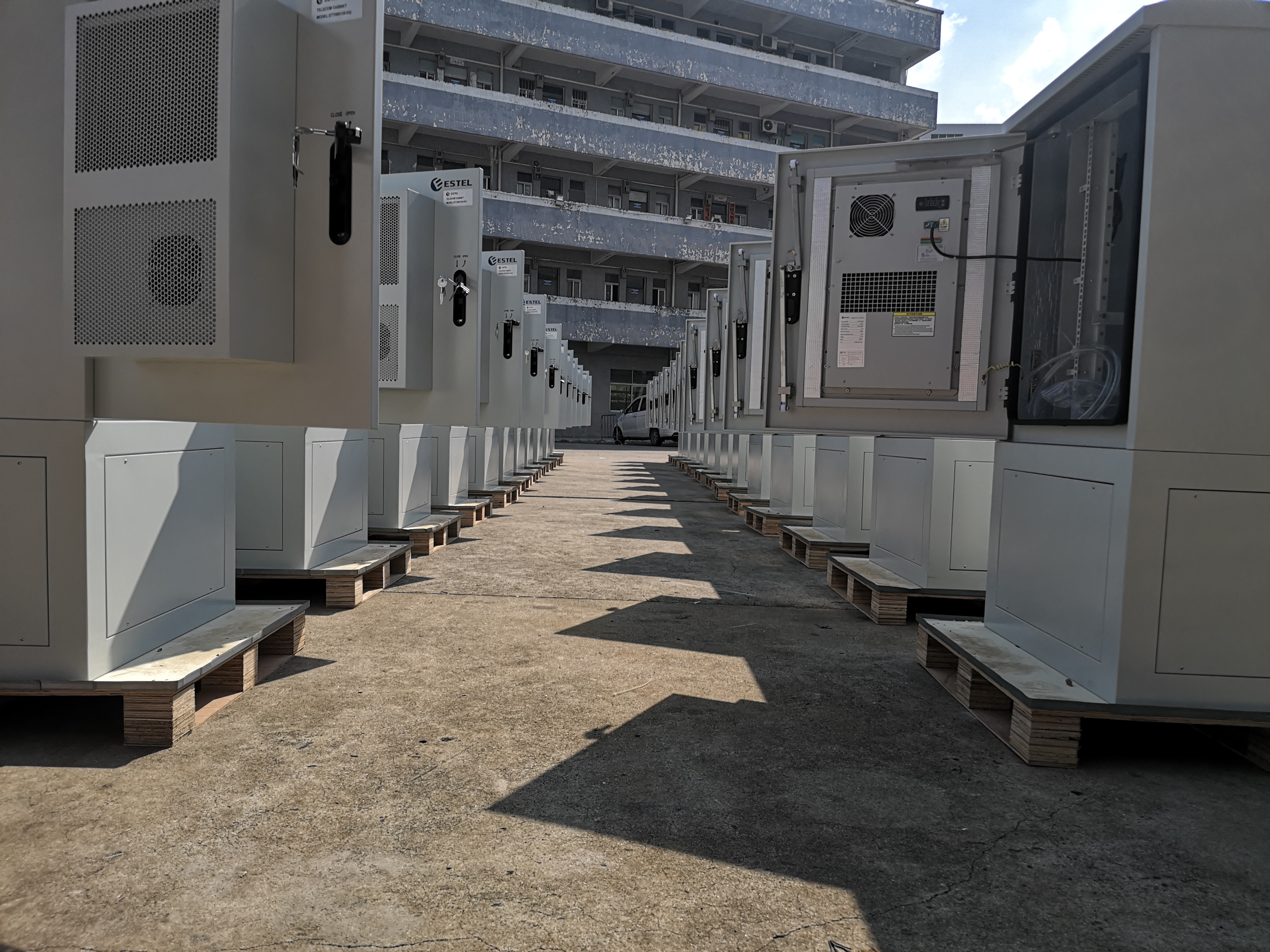

Outdoor Telecom Cabinet Power Reinforcement: Sealing Structure for Wind-Sand Impact & UV-Resistant Material Selection

Outdoor telecom cabinets protect sensitive equipment and keep networks running reliably. You face constant challenges from wind, sand, and UV exposure. The market for these cabinets reached USD 1.2 Billion in 2024 and may hit USD 2.5 Billion by 2033, with a projected CAGR of 9.1% from 2026 to 2033. You rely on Telecom Power Systems like DC48V, AC220V, UPS, and battery backup to maintain performance. Strong sealing and material choices help you overcome harsh outdoor conditions.

Key Takeaways

Choose cabinets with high IP and NEMA ratings to protect against dust, moisture, and harsh weather. This ensures your telecom systems remain reliable in challenging environments.

Use UV-resistant materials like polycarbonate and stainless steel to prevent degradation from sunlight. This choice extends the lifespan of your outdoor cabinets.

Implement regular maintenance checks on seals and cooling systems. This practice helps identify issues early and keeps your equipment running smoothly.

Combine sealing techniques with corrosion-resistant coatings for maximum protection. This strategy enhances durability against wind, sand, and moisture.

Invest in environmental testing to validate cabinet performance. This step helps uncover weaknesses before deployment, ensuring long-term reliability.

Telecom Power Systems: Sealing for Wind-Sand

Cabinet Vulnerabilities

You face many threats when you deploy Telecom Power Systems outdoors. Wind and sand can enter cabinets through small gaps, damaging sensitive electronics and reducing reliability. Dust can block cooling fans, causing overheating. Moisture can corrode connectors and circuit boards. Cabling connections often allow water and dust to enter, especially during storms or sandstorms. Chemicals and corrosive gases in the air can speed up wear and tear. You must address these vulnerabilities to keep your Telecom Power Systems running smoothly.

Tip: Always check for signs of dust buildup or corrosion around cable entry points and ventilation screens.

Sealing Design Principles

You need to follow industry standards to protect cabinets from wind and sand. The right sealing design keeps dust and moisture out and extends the life of your Telecom Power Systems. Use the following table to compare IP ratings and their protection levels:

IP Rating | Dust Protection Level | Recommended Use |

|---|---|---|

IP5X | Keeps out most dust, some may enter | Light outdoor use |

IP6X | Fully dust-tight | Dusty or harsh environments |

IP55 | Basic protection against dust and water jets | Moderate outdoor conditions |

IP66 | High protection against dust and water | Heavy dust, rain, or salt air conditions |

You should also consider NEMA standards for cabinet selection. NEMA 4X cabinets offer very high protection against wind, sand, and corrosion. See the table below for a quick comparison:

NEMA Rating | Description | Suitability for Wind-Sand Environments |

|---|---|---|

3 | Provides protection against rain and sleet | Moderate |

3R | Similar to NEMA 3 but with additional protection against falling rain | Moderate |

4 | Protects against splashing water and dust | High |

4X | Offers the same protection as NEMA 4 but with added corrosion resistance | Very High |

You should select cabinets with robust weatherproofing features. Sealing features prevent dust and moisture ingress. You must also consider temperature extremes and the effects of condensation. Reliable sealing design ensures your Telecom Power Systems operate without interruption.

Sealing Materials and Installation

You need high-quality sealing materials to block wind and sand. Use corrosion-resistant screens and dust-proof nets for ventilation openings. Install gaskets made from silicone or EPDM rubber around doors and cable entries. These materials resist UV, moisture, and temperature changes. Apply weatherproof sealants to joints and seams. Make sure all cable glands and connectors have tight seals. During installation, check that all seals fit snugly and leave no gaps.

Note: Proper installation of seals and screens prevents water and dust ingress at cabling connections, protecting your Telecom Power Systems from environmental damage.

Maintenance Tips

Regular maintenance keeps your sealed cabinets working well in harsh environments. You should inspect and clean corrosion-resistant screens and dust-proof nets to maintain airflow. Schedule daily, weekly, and monthly checks based on local dust levels. Clean or replace air filters to prevent airflow restriction. Inspect fan motors, seals, and cooler components every three to six months. Lubricate moving parts and check for leaks or corrosion.

You should inspect cabinet seals every three months for damage or wear. Increase inspection frequency during seasonal changes. Replace seals if you find cracks or gaps to prevent sudden failures. Seals block moisture, but they can trap humidity inside. Engineer humidity escape mechanisms and monitor internal conditions to prevent corrosion of connectors.

A campaign in Arizona showed that a sealed IP66 cabinet without airflow reached internal temperatures of 70 °C. After adding filtered fans and AC, the temperature dropped by 25 °C. This change doubled the life expectancy of the components inside. Routine maintenance of the cooling system is essential for keeping your Telecom Power Systems efficient and reliable.

UV-Resistant Material Selection

UV Impact on Materials

You face constant sunlight when you deploy outdoor cabinets. UV radiation breaks down plastics and coatings over time. You see fading, cracking, and loss of strength in materials that lack UV protection. Power system components inside the cabinet also suffer. UV rays can degrade insulation, wiring, and connectors. This damage leads to reduced performance and shorter equipment life.

Polycarbonate enclosures keep their strength and appearance after years in direct sunlight.

Stainless steel resists rust and corrosion, even in harsh environments.

Both materials withstand impacts, storms, and vandalism.

UV exposure causes some plastics to become brittle and discolored if you do not use UV-resistant grades.

Tip: Inspect cabinets regularly for signs of fading, cracking, or discoloration. Early detection helps you prevent equipment failure.

Selection Criteria

You need to choose materials that stand up to UV and extreme weather. Look for these qualities:

High UV resistance to prevent brittleness and fading.

Strong impact resistance for protection against storms and vandalism.

Corrosion resistance to handle moisture, salt, and chemicals.

Good thermal management to keep internal temperatures safe.

Compatibility with coatings and paints for extra protection.

You should also consider integrated cooling systems. These systems manage heat from sunlight and electronics. Air cooling uses ambient air to remove heat. Water or glycol systems adjust flow based on equipment load. Filtered fan units with high-density mesh and IP55-rated housing keep cabinets cool and block dust. Proper cooling prevents condensation and corrosion, which can cause component failure.

Note: If your cabinet cannot ventilate properly, heat builds up and damages sensitive equipment. Filtered fans remove heat and block harmful particles.

Material Comparison

You have several choices for cabinet materials. Each option offers different strengths and weaknesses. Use the table below to compare long-term performance:

Material | Long-term Performance Characteristics |

|---|---|

Polycarbonate | Exceptional impact resistance, UV-resistant coatings prevent brittleness and discoloration, maintains structural integrity. |

Stainless Steel | Exceptional durability, rust and corrosion resistance, withstands physical impacts and extreme weather conditions. |

Coated Aluminum | Lightweight, resists corrosion, dissipates heat efficiently, cost-effective with reliable performance. |

Polycarbonate gives you strong protection against impacts and UV rays. Stainless steel lasts for years and resists rust. Coated aluminum offers good heat dissipation and saves weight. You should match your choice to your local climate and risk factors.

Application Cases

You see real-world benefits when you select the right materials and cooling systems. Cabinets in desert regions use polycarbonate or stainless steel to resist sand, wind, and UV. Integrated cooling systems keep internal temperatures safe, even in direct sunlight. Air cooling works well in mild climates. Water or glycol systems handle heavy loads in hot areas. Filtered fan units maintain airflow and block dust.

You protect Telecom Power Systems by choosing UV-resistant materials and reliable cooling. These strategies help you avoid equipment failures and extend the life of your network.

Callout: Always match your cabinet material and cooling system to your environment. This approach ensures long-term reliability and reduces maintenance costs.

Integrated Reinforcement Strategies

Combining Sealing and Materials

You achieve the best protection for outdoor telecom cabinets when you combine advanced sealing techniques with UV-resistant materials. Weatherproof seals block water and dust, reducing the risk of short circuits. UV-resistant coatings prevent material degradation and keep cabinets strong for years. Corrosion-resistant coatings, such as zinc-aluminum alloys, add another layer of defense and help you meet environmental standards. When you use these strategies together, you create a cabinet that stands up to wind, sand, and sunlight.

Weatherproof seals prevent water ingress.

UV-resistant coatings maintain durability.

Corrosion-resistant finishes protect against harsh chemicals.

Tip: Always select materials and seals that match your local climate and environmental risks.

Integrated reinforcement strategies also improve reliability in challenging locations. In high-altitude areas, you need better cooling systems and greater insulation distances. Lower air pressure reduces the dielectric strength of air, so you must increase creepage and clearance distances to avoid electrical failures. Strong thermal management solutions help you combat ozone and UV damage, keeping your power systems safe.

Environmental Testing

You validate your cabinet’s performance through rigorous environmental testing. These protocols simulate real-world conditions and reveal weaknesses before deployment.

Testing Method | Purpose |

|---|---|

Temperature Cycling | Simulates real-world temperature variations to assess material response. |

Accelerated Life Testing (ALT) | Simulates long-term performance under high-stress conditions to identify weaknesses. |

Highly Accelerated Life Testing (HALT) | Tests products beyond operational limits to uncover potential failure points. |

Highly Accelerated Stress Screening (HASS) | Identifies manufacturing flaws under stress conditions similar to HALT. |

Environmental Stress Screening (ESS) | Checks for damage and performance degradation under various environmental factors. |

You also need corrosion resistance evaluation and salt spray testing. These tests ensure your cabinet materials withstand moisture, salt, and other outdoor hazards. Environmental testing helps you confirm that your reinforcement strategies work in practice.

Cost-Benefit Analysis

You see clear financial advantages when you invest in advanced sealing and UV-resistant materials. Durable cabinets resist UV damage and maintain reliability. Waterproofing features protect against moisture and contaminants. Robust materials reduce maintenance needs, saving you money over time.

Benefit | Description |

|---|---|

Durability | Advanced materials resist UV degradation, preventing premature aging and maintaining reliability. |

Waterproofing | Ensures protection against moisture and contaminants, crucial for outdoor environments. |

Maintenance Cost Reduction | Regular maintenance facilitated by robust materials extends lifespan and reduces repair costs. |

You lower maintenance costs by choosing ruggedized cabinets. Over five years, these cabinets reduce operational expenses and improve service reliability. Some cases show up to 33% savings over seven years. Enhanced features help you avoid rising expenses, making reinforced cabinets a smart long-term investment.

Callout: Investing in integrated reinforcement strategies protects your network and delivers lasting value.

You can reinforce outdoor telecom cabinets by choosing corrosion-resistant metals, applying UV-resistant coatings, and sealing against dust and moisture.

Use stainless steel or aluminum for durability.

Implement weather-tight seals and regular maintenance.

Practice | Benefit |

|---|---|

Environmental Testing | Early detection of weaknesses |

Power System Protection | Reliable network performance |

Routine Maintenance | Reduced risk of unexpected failures |

Adopt a holistic strategy. You will extend equipment lifespan, improve service reliability, and lower operational risks.

FAQ

What is the best way to check cabinet seals for damage?

You should inspect seals every three months. Look for cracks, gaps, or signs of wear. Use a flashlight to spot hidden issues. Replace damaged seals immediately to keep dust and moisture out.

How do UV-resistant materials improve cabinet lifespan?

UV-resistant materials block sunlight damage. You prevent fading, cracking, and brittleness. Cabinets last longer and protect your equipment better. Polycarbonate and stainless steel offer strong UV resistance.

Can I upgrade an existing cabinet for better wind-sand protection?

Yes, you can add silicone or EPDM gaskets, dust-proof screens, and weatherproof sealants. Make sure all cable entries have tight seals. Regular maintenance helps you keep the upgrades effective.

What maintenance schedule works best for outdoor telecom cabinets?

You should clean filters and screens monthly. Inspect seals and cooling systems every three months. Increase checks during dust storms or extreme weather. Consistent maintenance keeps your power systems reliable.

See Also

Essential Materials Needed for Durable Outdoor Telecom Cabinets

Key Features for Longevity in Outdoor Telecom Cabinets

Assessing Material Quality for Outdoor Telecom Cabinet Durability

Safeguarding Equipment Using Outdoor Telecom Cabinet Solutions

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA