EMC in Dense Telecom Cabinet Deployments: Crosstalk Suppression & Layout Optimization for Multiple Power Modules

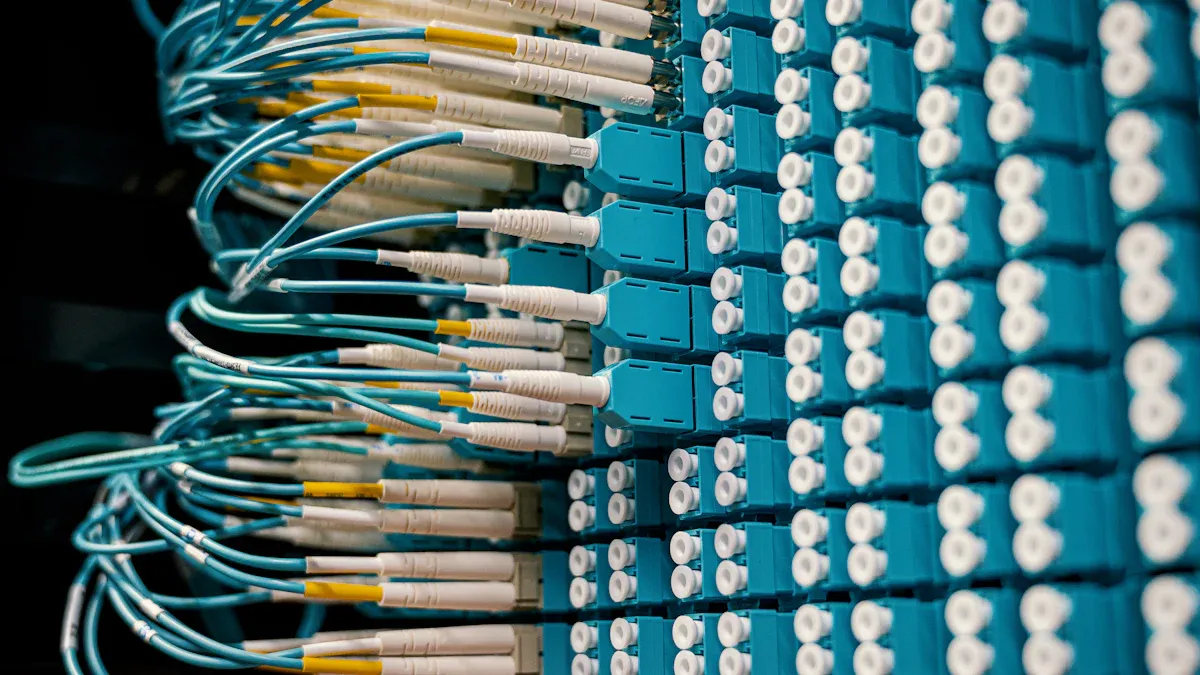

You face unique challenges when designing a cabinet for Telecom Power Systems. Crosstalk between modules can threaten signal integrity and disrupt your system. Reliability depends on how you place each module and route connections.

Prioritize strategic module placement

Focus on clear signal paths to reduce interference

Your attention to layout details ensures stable performance.

Key Takeaways

Strategic module placement is crucial. Keep noisy power modules away from sensitive components to reduce crosstalk and maintain signal integrity.

Use shielding and proper grounding techniques. Shielding materials like copper and aluminum can block interference, while solid grounding prevents unwanted currents.

Optimize cable management. Route cables along the cabinet sides and separate power from signal lines to enhance airflow and reduce electromagnetic interference.

Implement good routing practices on PCBs. Keep signal and power traces apart, use short trace lengths, and employ controlled impedance to improve signal quality.

Regularly test for emissions and immunity. Conduct tests under real conditions to identify potential issues and ensure your system meets EMC standards.

EMC in Telecom Power Systems

Cabinet Density Issues

You often see telecom power systems packed into cabinets with high density. This setup saves space but creates new challenges. When you increase density, you also increase the risk of electromagnetic interference. Each power module sits close to others, which makes it easier for signals to jump from one module to another. You must pay attention to how density affects airflow and heat. Poor airflow can cause overheating, which leads to performance drops or even failures. High density also makes it harder to separate noisy and sensitive circuits. You need to plan your cabinet layout carefully. Use physical barriers or shields to help reduce interference.

Tip: Always check the airflow paths in your cabinet. High density can block vents and fans, so you should test for hot spots.

Module Interference

In dense telecom power systems, module interference becomes a major concern. When modules operate close together, their electromagnetic fields can overlap. This overlap causes crosstalk, which disrupts signal integrity. You might notice random resets, data errors, or even total system failures. You should use twisted pair cables and shielded connectors to help reduce interference. Keep power and signal lines apart whenever possible. High density means you have less room for separation, so every inch counts. You must also ground each module properly. Good grounding helps control stray currents and reduces the risk of interference.

A table can help you track common interference sources in dense telecom power systems:

Interference Source | Impact on System | Mitigation Strategy |

|---|---|---|

Crosstalk | Data errors | Shielding, cable routing |

Overheating | Improved airflow | |

Ground loops | Noise spikes | Proper grounding |

You need to address these issues early in your design. High density in telecom power systems demands careful planning and constant testing. Your attention to detail will protect system reliability and performance.

Signal Crosstalk Suppression

Shielding Methods

You can use shielding to protect your telecom cabinet from unwanted interference. Shielding acts as a barrier that blocks electromagnetic fields from leaking between modules. When you install metal shields around sensitive modules, you help maintain signal integrity. You should select shield materials that match the frequency range of your system. Copper and aluminum work well for most telecom applications.

Tip: Place shields between power modules and signal modules. This step reduces crosstalk and keeps signal integrity high.

You can also use shielded cables. These cables have a metal layer that prevents outside noise from entering the signal path. When you connect modules with shielded cables, you lower the risk of crosstalk. Always ground the shield at one end to avoid ground loops. This practice helps you keep signal integrity stable.

Routing Practices

Good routing practices play a key role in crosstalk suppression. You should separate power and signal traces on your printed circuit boards. When you keep these traces apart, you reduce the chance of interference between modules. Try to route high-speed signal lines away from noisy power lines. This step protects signal integrity.

You can use the following checklist to improve your routing:

Route signal traces perpendicular to power traces when possible.

Keep trace lengths short between modules.

Avoid running parallel traces for long distances.

Use differential pairs for critical signals to boost signal integrity.

When you design the layout, group similar signals together. For example, keep all ground traces close to each other. This grouping helps you control the return path and reduces crosstalk. You should also use ground planes under signal traces. Ground planes act as shields and help maintain signal integrity across all modules.

Grounding & Filtering

Proper grounding and filtering are essential for crosstalk suppression. Each module needs a solid ground connection. When you connect all modules to a common ground point, you prevent unwanted currents from flowing between them. This setup keeps signal integrity intact.

You should use filters to block high-frequency noise. Ferrite beads and capacitors work well for this purpose. Place filters at the input and output of each module. This placement stops noise before it can spread to other modules. You can also use common-mode chokes to filter out noise that travels along multiple lines.

A simple table can help you choose the right filtering method:

Filter Type | Use Case | Benefit for Signal Integrity |

|---|---|---|

Ferrite Bead | Power lines between modules | Blocks high-frequency noise |

Capacitor | Signal lines near modules | Reduces voltage spikes |

Common-mode choke | Multiple lines in modules | Suppresses shared noise |

Note: Always test your grounding and filtering setup. Small changes can have a big impact on crosstalk and signal integrity.

When you combine shielding, smart routing, and strong grounding, you create a robust system. These steps help you protect signal integrity and ensure that all modules work together without interference.

Layout Design Optimization

Module Placement

You must approach module placement with a clear strategy. The way you arrange modules inside a telecom cabinet affects both electromagnetic compatibility and thermal management. Place noisy power modules away from sensitive optical module pcb assemblies. This separation reduces the risk of crosstalk and signal degradation. Always consider the airflow path. Good thermal management starts with a layout that allows cool air to reach every module and hot air to exit without obstruction.

You can use a grid layout to organize modules. This method helps you maintain consistent spacing and simplifies cable routing. When you follow a grid, you also make it easier to plan for future upgrades or miniaturization. Place high-speed modules in locations with the least interference risk. Keep thermal hotspots away from critical optical module pcb components. Use blank panels or shields between modules if space allows. These barriers improve both thermal and electromagnetic isolation.

Tip: Always map out your module placement on paper or with software before you start the physical build. This step helps you spot potential thermal or EMI issues early.

PCB Design

Your pcb design choices have a direct impact on system reliability and electromagnetic performance. Start by keeping trace lengths short and direct. Short traces reduce electromagnetic interference and improve signal quality. Use controlled impedance techniques for high-speed pcb design. Impedance matching prevents signal reflections and keeps your data clean.

Separate high-speed and low-speed traces on your optical module pcb. This separation minimizes interference and supports stable operation. Place ground and power planes beneath signal layers. These planes provide well-defined return paths and help control EMI. You should always use a grid approach when laying out traces. This method keeps your design organized and makes troubleshooting easier.

A well-designed optical module pcb supports both miniaturization and thermal management. Compact layouts save space, but you must avoid crowding traces or components. Leave enough room for thermal dissipation. Use thermal vias and copper pours to spread heat away from sensitive areas. Always check the thermal profile of your design before finalizing the layout.

Key features for EMI reduction in optical module pcb design:

Short, direct trace routing

Controlled impedance for high-speed signals

Separation of signal types

Ground and power planes for stable return paths

Note: Regularly review your optical module pcb layout for potential thermal bottlenecks. Early detection prevents costly redesigns.

Cable Separation

Cable management plays a vital role in maintaining both signal integrity and thermal performance. Route cables along the sides of the cabinet to keep airflow paths clear. Avoid running power and signal cables together. This separation reduces the chance of crosstalk and supports reliable operation of your optical module pcb assemblies.

Use cable trays or guides to enforce a grid pattern. This structure keeps cables organized and prevents tangling. When you follow a grid, you also make it easier to identify and replace cables during maintenance. Keep high-speed cables as short as possible. Short cables reduce EMI and improve data transmission. Always secure cables to prevent movement, which can cause wear or accidental disconnection.

Thermal management depends on clear airflow. Avoid blocking vents or fans with cables. Use cable ties or Velcro straps to bundle cables neatly. This practice not only improves thermal performance but also makes your cabinet look professional.

Alert: Overcrowded cables can trap heat and create thermal hotspots. Always check cable bundles for proper spacing.

A well-organized cabinet with strategic module placement, optimized optical module pcb design, and disciplined cable separation ensures high reliability. You support both electromagnetic compatibility and thermal management, which are essential for modern telecom systems.

Reliability & Performance Testing

Emissions Testing

You need to test emissions to ensure your telecom cabinet meets EMC standards. Emissions testing measures how much electromagnetic energy your system releases. High emissions can affect the performance of nearby equipment and reduce reliability. You should use specialized equipment to capture emissions from each power module. Place probes near cables and connectors to collect accurate data. Record the data at different frequencies and compare it to the limits set by industry standards. If you see emissions above the allowed level, adjust your layout or add shielding. This process helps you maintain high performance and protect the quality of your system.

Tip: Always test emissions with the cabinet fully loaded. This approach gives you a true picture of real-world performance and reliability.

Immunity Validation

Immunity validation checks how well your system resists external electromagnetic disturbances. You want your telecom cabinet to keep working even when exposed to noise. Follow these steps to validate immunity:

Set up your device under test (DUT) and test equipment according to the required standard.

Configure the signal generator, power amplifier, and coupling/decoupling network (CDN) to apply the correct disturbance.

Expose the DUT to the disturbance, using the specified test levels and frequency range.

Monitor the DUT’s performance during and after the test. Watch for data errors, malfunctions, or permanent damage.

If the DUT fails, find the root cause and improve your design to boost immunity.

You should repeat these tests after any design change. This practice ensures long-term operational reliability and consistent performance.

Mistakes to Avoid

Many engineers overlook common mistakes during EMC testing. You might forget to test with all modules running, which can hide real performance issues. Some teams skip monitoring data quality during tests, missing hidden errors. Others ignore cable routing, which can lead to unexpected crosstalk and lower reliability. Always document your test setup and results. This habit helps you track data and maintain high quality over time.

A table of common mistakes and solutions can help you avoid problems:

Mistake | Impact on Reliability & Performance | Solution |

|---|---|---|

Incomplete testing | Missed data errors | Test all scenarios |

Poor documentation | Lost data, lower quality | Keep detailed records |

Ignoring cable layout | Increased crosstalk, lower reliability | Plan cable routing |

Alert: Never assume your system will pass without thorough testing. Careful validation protects both performance and reliability.

You can achieve strong EMC performance in dense telecom cabinets by following a few key steps:

Separate noisy and sensitive modules.

Use shielding, smart routing, and solid grounding.

Organize cables and optimize PCB layouts.

Tip: Always test your system under real conditions. Careful validation helps you catch hidden issues and ensures reliable operation. EMC-focused design protects your network and keeps performance high.

FAQ

What is crosstalk in telecom cabinets?

Crosstalk happens when signals from one module interfere with another. You may see data errors or noise. Good shielding, smart cable routing, and proper grounding help you reduce crosstalk and keep your system stable.

How do you choose the right shielding material?

You should match the shield material to your system’s frequency range. Copper and aluminum work well for most telecom cabinets. Always ground the shield properly to block unwanted signals.

Why does cable separation matter for EMC?

Cable separation keeps power and signal lines apart. This step reduces interference and helps maintain signal quality. You also improve airflow, which supports better cooling and system reliability.

How often should you test for EMC compliance?

You should test after every major design change or upgrade. Regular testing helps you catch new issues early. Always test with the cabinet fully loaded to see real-world performance.

See Also

Understanding Telecom Cabinets: Structure and Associated Costs

Ensuring Consistent Power Supply for Telecom Cabinets

Solar Energy Storage Solutions for Telecom Cabinet Systems

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA