Telecom Power Systems heat dissipation design and insulation reinforcement at high altitudes under low pressure conditions

Telecom Power Systems face unique challenges at high-altitude sites where air density drops to nearly 7% of sea level values. This significant reduction in air density weakens natural cooling and lowers the dielectric strength of air, increasing the risk of insulation breakdown. Engineers must rely on advanced modeling, simulation, and careful material selection to overcome these environmental limitations.

Key Takeaways

High altitudes reduce air density, which lowers cooling efficiency and raises equipment temperatures, so engineers must use active ventilation and smart layouts to keep systems cool.

Lower air pressure at altitude weakens air's insulation ability, requiring increased creepage and clearance distances to prevent electrical breakdown and ensure safety.

Choosing strong insulation materials like polyethylene roll and high-performance plastics helps protect telecom systems from electrical discharge and harsh environmental conditions.

Following international standards and applying altitude correction factors ensures telecom power systems remain reliable, safe, and compliant in high-altitude sites.

Regular maintenance and real-time temperature monitoring extend equipment life and prevent overheating in challenging high-altitude environments.

Altitude Effects

Air Density and Cooling

High-altitude environments present significant challenges for cooling in Telecom Power Systems. As altitude increases, air density drops, which directly impacts the efficiency of convective heat transfer. Lower air density means less mass flow for a given volumetric airflow, causing fans and heat sinks to operate less effectively. This reduction in cooling capacity leads to higher operating temperatures, which can accelerate material fatigue and reduce equipment efficiency.

Low atmospheric pressure at high altitudes reduces air density, leading to less effective convective cooling.

Reduced cooling causes higher operating temperatures in telecom equipment, accelerating material fatigue and reducing efficiency.

Equipment ratings, such as voltage ratings of solar modules, must be adjusted downward to compensate for low-pressure conditions.

System design should include adjustments in equipment spacing and mounting to optimize heat dissipation under reduced air density.

Careful selection of components with appropriate temperature coefficients and UV resistance helps maintain performance and reliability.

The following table summarizes how reduced air density affects the convective heat transfer coefficient in telecom enclosures:

Aspect | Explanation |

|---|---|

Air density effect | Air density decreases with altitude, reducing the mass flow rate. |

Impact on Reynolds number | Lower mass flow reduces Reynolds number, lowering the Nusselt number. |

Heat transfer coefficient | h varies with mass flow rate to the power of 0.8 (h ~ mass flow rate^0.8). |

Air properties variation | Viscosity and thermal conductivity change slightly, minimal effect on h. |

Fan performance | Conventional fans maintain volumetric flow but lose mass flow at altitude. |

Overall effect | Reduced air density decreases convective cooling effectiveness. |

Modeling and simulation play a crucial role in designing cooling and ventilation systems for telecom shelters at high altitudes. Engineers use these tools to predict airflow patterns, temperature rise, and optimize equipment placement for maximum heat dissipation.

Pressure and Insulation

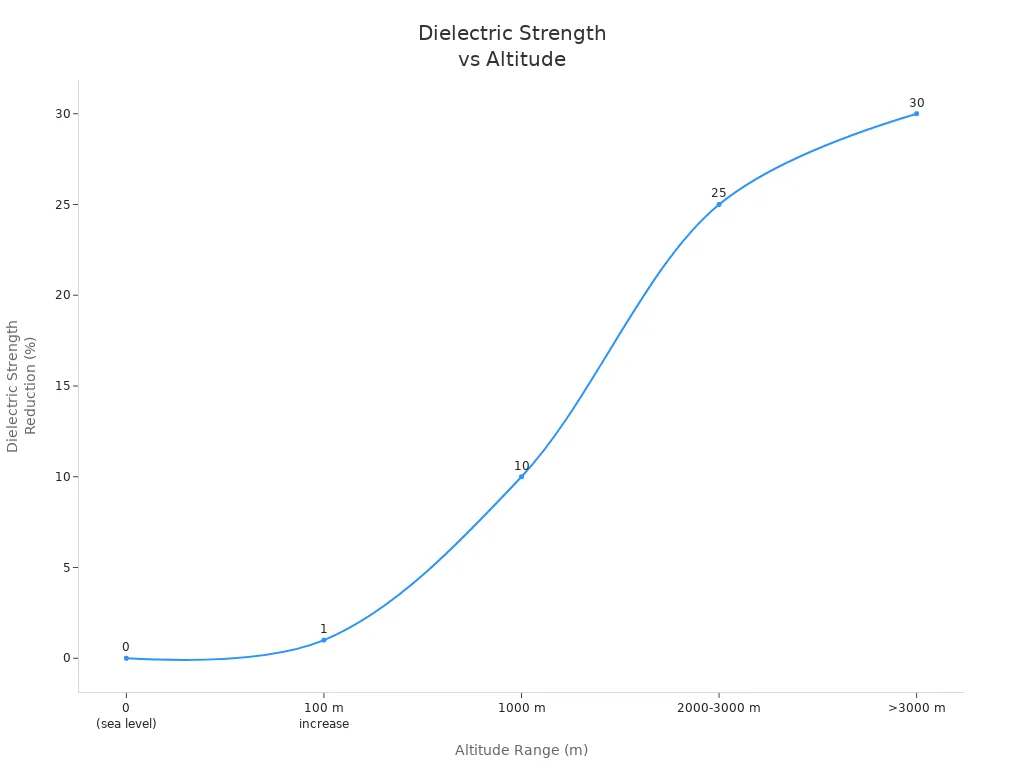

Atmospheric pressure drops as altitude increases, which reduces the dielectric strength of air. This change increases the risk of electrical flashover and corona discharge in high-voltage systems. The dielectric strength of air decreases by about 1% for every 100 meters of altitude gained. At altitudes above 2000 meters, insulation clearances must increase by 20–30% to prevent breakdowns.

International standards, such as IEC 60071 and IEEE C37.100.1, provide altitude correction factors. These guidelines help engineers adjust insulation distances and derate voltage ratings to maintain system reliability. Modeling and simulation also assist in evaluating insulation performance under low-pressure conditions, ensuring Telecom Power Systems operate safely and efficiently.

Telecom Power Systems Cooling

Enhanced Ventilation

Effective ventilation design remains critical for maintaining safe operating temperatures in Telecom Power Systems at high altitudes. Reduced air density limits the effectiveness of natural convection, so engineers must adopt active and optimized ventilation strategies. The following approaches help address these challenges:

Forced air cooling with adjustable fan speeds compensates for thinner air and reduced cooling capacity.

Optimizing cabinet layouts by spacing equipment, using blanking panels, and positioning high-power devices near airflow sources improves internal airflow.

Regular maintenance, including cleaning filters and vents, prevents dust buildup and ensures consistent airflow.

Integrating temperature sensors near heat sources and fans enables real-time monitoring and predictive maintenance, reducing the risk of overheating.

Advanced cooling solutions, such as air-to-air heat exchangers, modular heat sinks, and liquid cooling, manage high heat loads and enhance reliability.

Derating power output at higher altitudes and temperatures helps prevent overheating.

Shielding equipment from direct sunlight and avoiding placement near other heat sources further supports effective heat dissipation.

Tip: Consistent maintenance and real-time monitoring can significantly extend the lifespan of Telecom Power Systems operating in harsh, high-altitude environments.

Shielded Cable Benefits

Shielded cables, such as F/UTP types, offer distinct advantages for heat dissipation in high-altitude telecom installations. These cables feature metallic shielding that not only reduces electromagnetic interference but also improves thermal conductivity. Enhanced heat transfer through the cable jacket helps dissipate localized heat, especially in densely packed enclosures. Shielded cables also provide better protection against ozone and ultraviolet exposure, which are more intense at higher elevations. By selecting shielded cables, engineers can improve both the electrical performance and thermal management of Telecom Power Systems.

Thermal Management Upgrades

Upgrading thermal management systems becomes essential for reliable operation at altitude. Advanced cooling solutions require ruggedized designs to withstand extreme temperature swings, dust, and moisture. These systems often include adaptive energy management and durable enclosures. While these upgrades increase both capital and operational costs, they deliver significant benefits in reliability and efficiency.

Cost Component | Description | Cost Implication for Advanced Cooling in High-Altitude Systems |

|---|---|---|

Capital Costs | Major system components like condensers, cooling towers, pumps, water treatment, etc. | Advanced cooling (dry, hybrid) generally have higher capital costs than conventional wet cooling. |

Operating & Maintenance Costs | Power for pumps/fans, water makeup, routine inspections, repairs, cleaning. | Higher O&M costs due to complexity and less water availability at altitude. |

Penalty Costs | Efficiency and capacity losses due to cooling system choice. | Dry and hybrid systems may reduce plant output and efficiency, increasing penalty costs. |

Water Conservation | Dry and hybrid systems save 75-95% of water compared to wet cooling. | Water savings come at a significant cost premium, e.g., $1,000-$2,000 per acre-foot saved. |

Site Factors | Elevation, meteorology, water availability, system complexity influence costs. | High-altitude sites increase complexity and cost due to harsher conditions and limited water. |

Ozone generation presents another challenge at high altitudes. Increased ultraviolet radiation can lead to higher ozone levels, which accelerate insulation aging and degrade materials. Robust thermal management solutions, including ozone-resistant materials and enhanced ventilation, help mitigate these risks and ensure long-term system performance.

Insulation Reinforcement

Creepage and Clearance

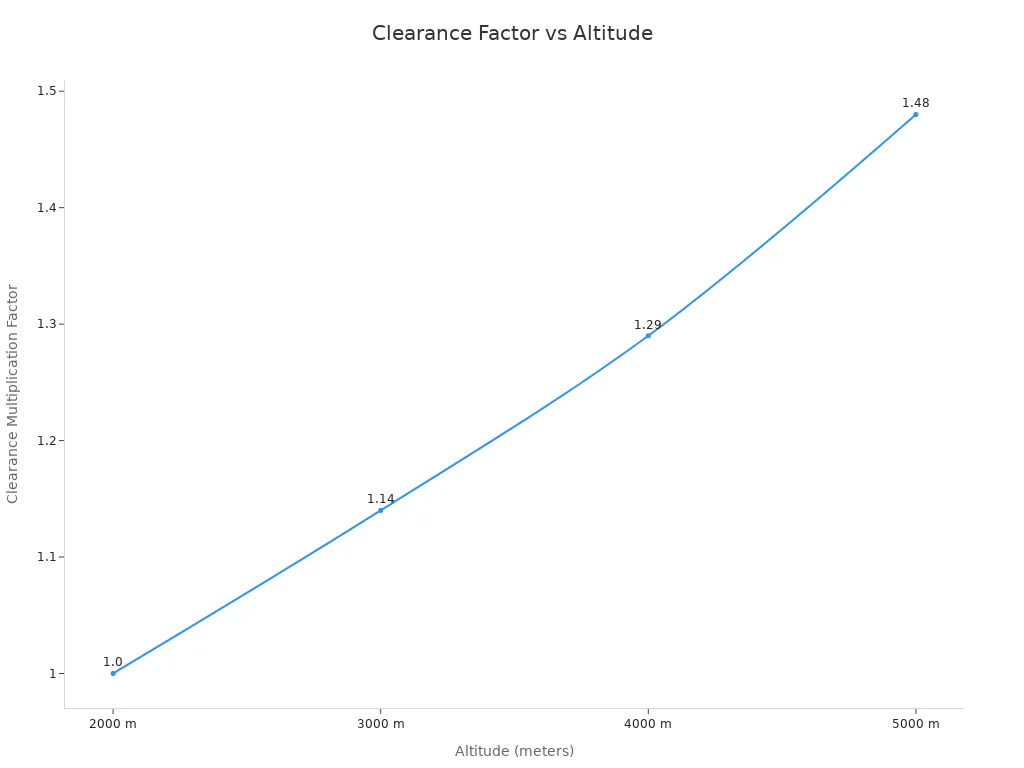

Engineers must increase creepage and clearance distances to maintain insulation integrity in high-altitude environments. As air pressure drops, the dielectric strength of air decreases, making electrical breakdown more likely. Clearance distance refers to the shortest air gap between conductive parts, while creepage distance is the shortest path along an insulating surface. Both must be adjusted to prevent arcing and surface tracking.

The IEC 60664-1:2007 standard provides altitude correction factors for clearance distances. For installations above 3000 meters, designers multiply clearance distances by 1.14 to compensate for reduced air density. Creepage distances also require adjustment based on voltage, pollution degree, and material group, following IPC-2221 and IEC-60950-1 guidelines.

Altitude (meters) | Clearance Multiplication Factor |

|---|---|

2000 | 1.00 |

3000 | 1.14 |

4000 | 1.29 |

5000 | 1.48 |

Increasing these distances reduces the risk of insulation breakdown, arcing, and partial discharge. The following chart illustrates how the clearance multiplication factor rises with altitude:

Note: Proper adjustment of creepage and clearance distances is essential for reliable operation of Telecom Power Systems at high altitudes.

Material Selection

Selecting the right insulation materials is critical for maintaining dielectric strength under low-pressure, high-altitude conditions. High-performance thermoplastics such as PEEK, Ultem™, Torlon®, and Vespel® offer excellent electrical insulation and stability in harsh environments. PEEK provides a low dielectric constant and resists thermal and mechanical stress. Ultem™ delivers high dielectric strength and flame resistance, meeting aerospace safety standards.

Polyimide films and Nomex® aramid paper also demonstrate strong dielectric properties and thermal resilience. Nomex® resists moisture and flame, making it suitable for challenging conditions. RTV silicone rubber coatings enhance hydrophobicity and protect insulator surfaces, helping maintain dielectric strength under environmental stress.

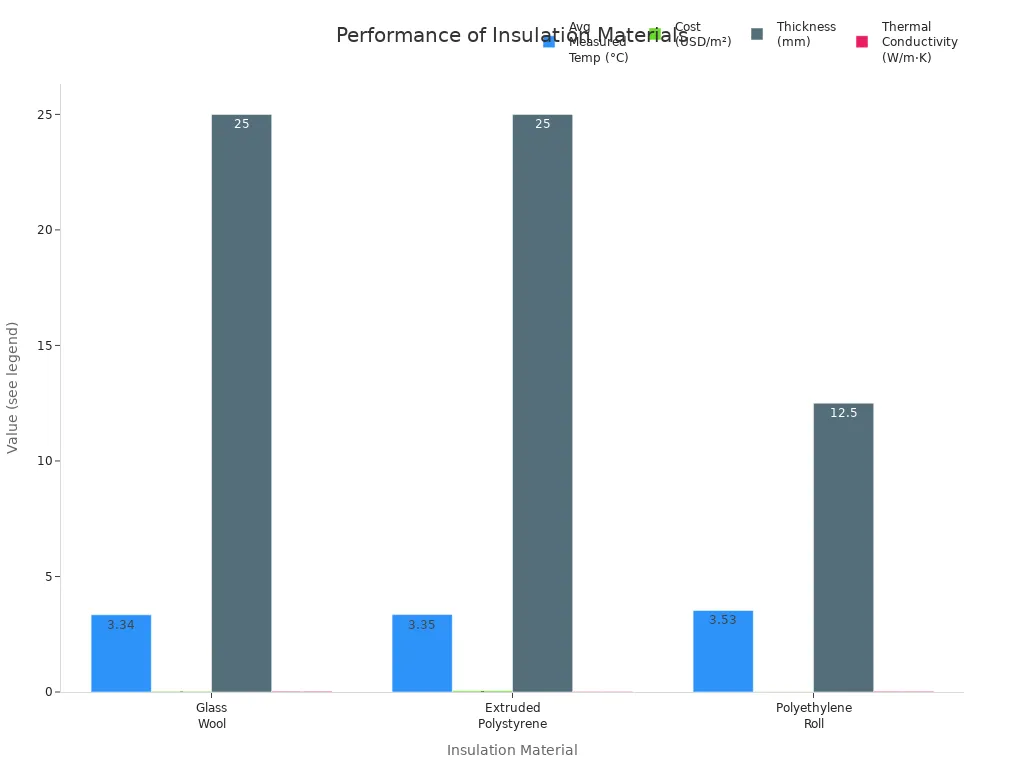

The table below compares common insulation materials used in high-altitude telecom applications:

Insulation Material | Avg. Measured Temp (°C) | Cost (USD/m²) | Thickness (mm) | Thermal Conductivity (W/m·K) | Cost-Effectiveness | Ease of Application | Environmental Impact | Fire Resistance | Useful Life |

|---|---|---|---|---|---|---|---|---|---|

Glass Wool roll | 3.34 | 0.03 | 25 | 0.032 | Medium | Low | Some fiber safety concerns | Class A1 | Long |

Extruded Polystyrene sheet | 3.35 | 0.05 | 25 | 0.026 | Low | Medium | HCFCs affect ozone layer | Class ABS3837 | Long |

Polyethylene roll | 3.53 | 0.01 | 12.5 | 0.0298 | High | High | Non-toxic, environmentally safe | Class A ASTM E-84 | Long |

Polyethylene roll insulation stands out for its thermal efficiency, cost-effectiveness, and environmental safety. Engineers often choose this material for Telecom Power Systems in cold, high-altitude regions.

Discharge Prevention

Electrical discharge risks increase with altitude due to lower air density and reduced dielectric strength. Thinner air makes arcing and insulation breakdown more likely. Lower humidity at high altitudes can cause static electricity buildup, further raising discharge risk. Equipment rated for operation up to 2,000 meters may require manufacturer consultation and altitude-specific adjustments above this threshold.

The most significant insulation failure risks include:

Reduced air density lowers the insulating ability of air inside MCCBs, increasing flashover risk.

Without proper derating, arc faults, flashovers, and equipment explosions may occur.

Operational failures such as nuisance trips and delayed protection can compromise safety.

Lower dielectric strength raises the likelihood of short circuits and equipment damage.

Partial discharge inception voltage (PDIV) decreases as altitude increases. Lower air pressure intensifies corona discharge effects, making insulation more prone to failure. Environmental factors such as increased moisture and water seepage can promote corrosion and further impact insulation performance.

Tip: Use altitude-rated equipment and robust insulation materials to minimize discharge risks in Telecom Power Systems deployed at high elevations.

Standards and Guidelines

Altitude-Rated Equipment

Telecom power systems installed at high altitudes must comply with strict international standards to ensure safety and reliability. IEC 60068-2-13 specifies environmental testing requirements, including altitude limits for both operating and non-operating conditions. UL 60950-1 and IEC 60950-1 address safety standards for telecom equipment, focusing on electrical protection and insulation. These standards help engineers select and certify equipment that can withstand the unique challenges of high-altitude environments.

Aspect | Conditions / Standards |

|---|---|

Altitude | Operating up to 3000 m (10,000 ft) and Non-operating up to 12,000 m (40,000 ft) per IEC 60068-2-13 |

Vibration | Operating and Non-operating vibration tests specified by IEC 60068-2-13 |

Safety | Compliance with UL/CSA-60950-1, EN60950-1, IEC60950-1 and related safety standards |

Regulatory standards also require telecom cabinets to meet GR-487, NEBS Level 3, and IP/NEMA ratings. These certifications guarantee protection against moisture, dust, UV exposure, and extreme weather. Cabinets with integrated cooling systems, such as heat exchangers and fans, maintain safe operating temperatures and prevent thermal stress. These features extend equipment life and support continuous network operation in remote or harsh locations.

Compliance Requirements

Manufacturers provide specific recommendations for deploying telecom power systems at high altitudes. Astrodyne TDI advises engineers to apply derating above 2000 meters because lower air density reduces cooling efficiency. The amount of derating depends on the power supply type. They recommend integrating advanced cooling solutions to maintain maximum output and prevent overheating.

Schneider Electric notes that circuit breakers perform reliably up to 2000 meters. Above this altitude, engineers must apply correction factors to account for reduced dielectric strength and diminished cooling capacity. These adjustments ensure safe operation and prevent insulation breakdown.

Tip: Always consult manufacturer guidelines and apply altitude correction factors when selecting and installing telecom power systems for high-altitude sites. This practice helps maintain safety, reliability, and compliance with international standards.

Aspect | Evidence Summary |

|---|---|

Regulatory Standards | Cabinets comply with GR-487, NEBS Level 3, IP/NEMA ratings, and fire/electrical safety codes. |

Thermal Management | Active cooling systems maintain safe temperatures and prevent equipment failure. |

Environmental Protection | Cabinets are sealed to protect against moisture, corrosion, dust, UV, and extreme weather. |

Equipment Longevity & Network Uptime | Active cooling extends hardware life and supports continuous operation. |

Deployment Versatility | Integrated cooling enables deployment in remote or high-altitude locations. |

Engineers must address unique challenges when designing Telecom Power Systems for high-altitude sites. They should focus on enhanced cooling, increased insulation distances, and careful material selection. Following international standards and using modeling tools ensures reliable operation. A practical checklist helps engineers verify ventilation, insulation, and compliance before deployment.

Tip: A thorough review of all design factors reduces the risk of failure in high-altitude Telecom Power Systems.

FAQ

What is the main challenge for telecom power systems at high altitudes?

Reduced air density limits cooling efficiency. Lower atmospheric pressure decreases the dielectric strength of air. These factors increase the risk of overheating and insulation breakdown in telecom equipment.

How do engineers improve heat dissipation in high-altitude telecom shelters?

Engineers use forced ventilation, advanced heat sinks, and shielded cables. They optimize equipment layout and monitor temperatures with sensors. These strategies help maintain safe operating conditions.

Which insulation materials work best for high-altitude environments?

Polyethylene roll, PEEK, and Ultem™ provide strong dielectric properties and thermal stability. Nomex® and polyimide films resist moisture and flame. These materials protect equipment from electrical discharge and environmental stress.

Why must creepage and clearance distances increase at high altitudes?

Lower air pressure reduces the insulating ability of air. Engineers increase creepage and clearance distances to prevent arcing and surface tracking. International standards specify multiplication factors for these adjustments.

What standards guide telecom power system design for high-altitude sites?

IEC 60068-2-13, UL 60950-1, and IEC 60950-1 set requirements for altitude-rated equipment. GR-487 and NEBS Level 3 ensure environmental protection. Manufacturers provide altitude-specific recommendations for safe deployment.

See Also

Exploring Various Cooling Techniques For Telecom Cabinet Systems

Tips To Maintain Ideal Temperatures In Outdoor Telecom Cabinets

Selecting The Most Effective Cooling Solution For ESTEL Cabinets

Outdoor Communication Telecom Cabinets Equipped With Specialized Air Conditioning

Methods For Calculating Power Systems And Batteries In Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA