Noise Control in Telecom Cabinet Power System Cooling: Intelligent Fan Speed Adjustment & Soundproof Material Selection

You can significantly reduce noise in Telecom Power Systems by using intelligent fan speed adjustment, soundproof materials, and electromagnetic noise control methods. When you optimize fan speed with advanced detection and control, you lower noise levels while keeping system temperatures stable. For example, modern fans with 256 speed levels adapt to changing conditions, which helps minimize noise and power use. Adding soundproof materials further blocks unwanted sounds. By focusing on both acoustic and electromagnetic noise, you protect signal quality and ensure your equipment runs efficiently.

Key Takeaways

Intelligent fan speed control adjusts cooling based on temperature, reducing noise and energy use while extending equipment life.

Using soundproof materials like mass loaded vinyl and acoustic foam can significantly lower noise levels in telecom cabinets.

Proper cable management and electromagnetic noise control techniques help maintain signal integrity and reduce interference.

Regular maintenance and monitoring of noise control measures ensure long-term effectiveness and reliability in telecom power systems.

Combining intelligent fan controls, soundproofing, and electromagnetic noise strategies creates a quieter and more efficient environment for telecom equipment.

Noise Sources

Understanding the main noise contributors in Telecom Power Systems helps you target the most effective solutions. Both mechanical and electromagnetic sources play a role in overall noise levels.

Fans and Airflow

Fans stand out as the primary source of mechanical noise in Telecom Power Systems. You often hear sharp peaks in the noise spectrum from blade passing frequencies. Flow noise, while present, is about 10 dB lower than the noise from the fan blades. The interaction between airflow and the cabinet structure can further complicate the noise profile. If you reduce fan noise, you will notice a significant drop in total system noise.

Noise Source | Description | Significance |

|---|---|---|

Cooling Fans | Generate noise through blade passing frequency and flow noise | Blade passing frequencies are sharp peaks in the noise spectrum, while flow noise is approximately 10 dB lower. |

Airflow without Fan | Contributes to noise levels in the cabinet | Less significant than fan noise but still relevant. |

Interaction with Cabinet Structure | Complicates overall noise profile | If fan noise decreases, total noise will also decrease. |

You can see the impact of these sources in real-world measurements:

The running noise of a data center reaches 75 dB.

A BladeCenter chassis produces 74 dB.

Passive noise reduction can lower system noise from 75 dB to 53 dB.

Electromagnetic Interference

Electromagnetic interference (EMI) can disrupt both equipment and signals in Telecom Power Systems. EMI often comes from power lines, switching devices, and other electronic components. You can use EMI/EMC filters, ferrite beads, and shielding to block or absorb unwanted electromagnetic noise. These methods help maintain signal integrity and reduce the risk of equipment malfunction.

Cable and Power Line Proximity

The way you arrange cables and power lines affects noise levels in Telecom Power Systems. Two main types of coupling can introduce noise:

Capacitive Coupling: Occurs when conductors are exposed to varying electric fields, which can induce voltage in nearby wires. The effect depends on the distance and insulation between conductors.

Inductive Coupling: Happens when magnetic fields from one conductor induce current in another, similar to a transformer.

To reduce these effects, you should increase the distance between power and telecom lines, arrange conductors carefully, and maintain your equipment. These steps help minimize interference and keep your system running smoothly.

Intelligent Fan Speed Adjustment

Fan Speed Control

Intelligent fan speed control gives you the ability to adjust fan speed based on real-time temperature and system needs. This approach helps you maintain the right balance between cooling and noise. When the temperature inside your cabinet rises, the system increases fan speed to provide more airflow. When the temperature drops, the fans slow down, which reduces noise and saves energy.

Intelligent fan speed control adjusts the fan speed according to temperature and system requirements, minimizing noise while ensuring proper cooling.

In quiet environments such as offices or data centers, lowering fan speed can make a noticeable difference in noise levels, creating a more comfortable workspace.

Running fans at lower speeds also reduces wear, which extends the lifespan and reliability of your cooling equipment. This is especially important for the long-term performance of Telecom Power Systems.

You can find ultra-quiet fan systems like the AIRPLATE T3, which operates at just 18 dBA. Choosing the right fan system helps you achieve both effective cooling and low noise.

Noise Reduction Benefits

When you use intelligent fan speed adjustment, you gain several important benefits:

Lower noise levels create a better working environment for staff and reduce distractions.

Reduced fan speed means less vibration and mechanical stress, which leads to longer equipment life.

Energy consumption drops because fans only run as fast as needed, which lowers your operating costs.

Consistent cooling performance helps protect sensitive electronics in Telecom Power Systems from overheating.

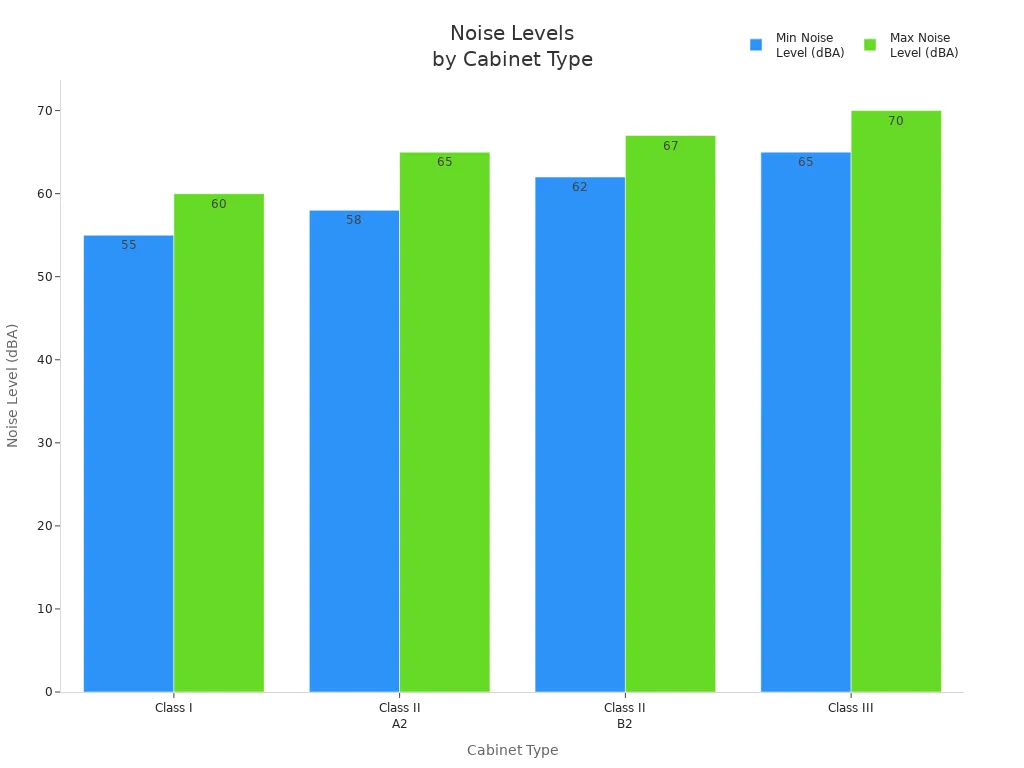

The following table shows typical noise levels for different cabinet types, helping you understand what to expect when you implement low-noise fans and variable speed compressors:

Cabinet Type | Typical Noise Level Range (dBA) | Measurement Conditions and Notes |

|---|---|---|

Class I | 55-60 | Measured at operator position under controlled conditions; simpler design results in lower noise levels. |

Class II A2 | 58-65 | Noise measured at 1 meter distance, seated operator height; balances protection and noise, common in labs. |

Class II B2 | 62-67 | Higher noise due to increased airflow and filtration; measurements follow NSF/ANSI 49 standard (max 67 dBA). |

Class III | 65-70 | Highest noise levels due to enclosed design and complex filtration; measurements standardized for comparability. |

Implementation Tips

You can maximize the benefits of intelligent fan speed adjustment by following these best practices:

Use automatic cooling systems with temperature sensors. These systems operate fans only when necessary, which improves energy efficiency.

Regularly check filters and keep the area around your cabinet clear. Good ventilation helps your fans work more effectively.

Set up temperature alarms to detect problems early and maintain optimal cooling.

Make sure your fans draw in cool air and avoid clutter inside the cabinet to optimize airflow.

Consider active cooling methods for precise control and better heat removal.

Use cooling fans as a key part of outdoor cabinet cooling, either alone or in hybrid systems.

Pressurize cabinets by pushing cool air in. This reduces noise and keeps dust out, which lowers maintenance costs.

Tip: Regular maintenance and proper sensor placement help you avoid reliability issues and ensure your cooling system works as intended.

You may face some challenges during implementation. The table below highlights common issues and solutions:

Challenge | Solution |

|---|---|

Overheating Risks | Use integrated fan systems and HVAC modules to manage heat load and prevent overheating. |

Equipment Damage | Implement effective cooling systems and real-time monitoring to protect against high temps. |

Reliability Issues | Regular maintenance and proper sensor placement ensure reliable monitoring and operation. |

By following these steps, you can achieve quieter, more efficient, and more reliable cooling for your telecom cabinets.

Soundproof Material Selection

Material Types

You have several options when you want to reduce noise in telecom cabinet cooling systems. Each material offers unique properties that help block or absorb sound.

Sound dampened server racks provide a practical solution for noise control. These racks use built-in soundproofing layers to reduce the transmission of noise from fans and other components.

Mass loaded vinyl works well for blocking sound. Its limpness makes it more effective than stiff materials like steel.

Acoustic metamaterials, such as the Segmented Membrane Sound Absorber (SeMSA), target low-frequency and tonal noise. You can use these materials to address the specific noise profile of cooling fans.

Sound dampening foams absorb sound waves and reduce transmission inside server racks.

Note: While these materials may not eliminate noise completely, you can expect a significant reduction in overall sound levels.

The following table summarizes the key properties of common soundproof materials:

Material | Key Property |

|---|---|

Mass Loaded Vinyl | Limpness aids in sound blocking |

Acoustic Metamaterials | Effective for low-frequency noise absorption |

Sound Dampening Foams | Reduces sound transmission in server racks |

You can tailor acoustic metamaterials to target specific noise frequencies, which makes them especially useful for the unique challenges in Telecom Power Systems.

Selection Criteria

You should consider several factors when choosing soundproof materials for your telecom cabinets.

Noise Frequency: Identify the main frequencies produced by your cooling fans. Acoustic metamaterials work best for low-frequency noise, while foams handle higher frequencies.

Space Constraints: Measure the available space inside your cabinet. Some materials, like mass loaded vinyl, require more room for installation.

Durability: Select materials that withstand heat, humidity, and vibration. Mass loaded vinyl and high-density foams offer good durability.

Ease of Installation: Choose materials that you can install without major modifications to your cabinet.

Cost: Balance performance with budget. Acoustic metamaterials may cost more but deliver targeted noise reduction.

Tip: You can combine different materials to achieve better results. For example, use mass loaded vinyl for blocking and foam for absorption.

Installation

Proper installation maximizes the effectiveness of soundproof materials in your telecom cabinets. You should follow these techniques to get the best results:

Use high-density acoustic foam to absorb sound waves and reduce echo inside the enclosure.

Seal gaps with strips to maintain structural integrity and prevent vibrations from escaping.

Install vibration dampeners on components like cooling fans to absorb mechanical noise.

Measure sound levels before and after installation to evaluate the improvement.

Technique | Description |

|---|---|

High-density acoustic foam | Absorbs sound waves, reducing echo and reverberation inside the enclosure. |

Sealing gaps | Use sealing strips to close gaps, ensuring structural integrity and preventing vibrations. |

Vibration dampeners | Absorb vibrations from components like cooling fans, reducing mechanical noise. |

Sound level measurement | Measure noise levels before and after installation to evaluate effectiveness. |

You should inspect your cabinet regularly to ensure that soundproof materials remain in good condition. Replace worn or damaged materials to maintain optimal noise reduction.

Reminder: You can achieve the best results by combining soundproofing with intelligent fan speed adjustment and electromagnetic noise control. This integrated approach delivers quieter and more reliable Telecom Power Systems.

Electromagnetic Noise Control in Telecom Power Systems

Electromagnetic noise can disrupt signals and cause equipment failures in Telecom Power Systems. You can use several effective techniques to suppress this interference and keep your systems running smoothly.

EMI/EMC Filters

You should install EMI/EMC filters to clean up electrical signals. These filters absorb or reflect high-frequency noise, which results in a cleaner signal output. EMI filters work best when placed close to the source of interference. Ferrite beads also help by converting unwanted electromagnetic energy into heat, which reduces noise on power and signal lines.

Technique | Description |

|---|---|

Conductive Enclosures | Enclose devices within conductive materials to block EMI. |

Faraday Cages | Redirect and dissipate electromagnetic waves, shielding sensitive equipment. |

Shielding Gaskets and Seals | Use conductive gaskets to block EMI leakage and maintain a continuous conductive path. |

Conductive Coatings | Apply coatings to reflect or absorb electromagnetic radiation on device surfaces. |

Shielding Films and Tapes | Use thin conductive layers for flexible shielding on various surfaces. |

Grounding and Bonding | Connect shielding components to a common ground to divert unwanted electromagnetic energy. |

Filtering and Ferrite Materials | Use ferrite beads and filters to suppress high-frequency noise on cables and pathways. |

Tip: Place EMI filters and ferrite beads on both power and signal lines for maximum noise reduction.

Ferrite Beads and Shielding

You can use ferrite beads to suppress high-frequency noise. These beads work by absorbing electromagnetic energy and converting it into heat. Shielding techniques also play a key role. You should select materials like aluminum, copper, or silver for electrical fields, and mu-metal or iron for magnetic fields. For best results, ensure metal-to-metal contact through welding or soldering. Use EMI shielding gaskets for removable panels and keep mating surfaces clean.

Shielding films and tapes offer flexible options for surfaces with unusual shapes.

Grounding and bonding help divert unwanted energy away from sensitive equipment.

Cable Management

Proper cable management reduces electromagnetic interference and keeps your Telecom Power Systems reliable. Twisted pair cables are designed to minimize EMI, which helps maintain stable Ethernet connections. Organized cable layouts decrease clutter and lower the risk of interference from nearby cables.

Separation Requirement | Distance from Power Conductors | Distance from Fluorescent Lights |

|---|---|---|

Minimum Separation | 5 cm (2 inches) | 120 mm (5 inches) |

You should design your network to maintain separation between telecommunications and power pathways. Use horizontal and vertical cable management to prevent tangling and allow quick access. Place high-density components at the bottom of the rack to improve airflow and reduce overheating. Cable trays or ducts help minimize interference between power and data cables.

Note: Combining cable management with shielding and filtering techniques gives you the best protection against electromagnetic noise.

Integration

Combined Approach

You can achieve the best noise reduction by combining intelligent fan speed adjustment, soundproof material selection, and electromagnetic noise control. Each method targets a different type of noise. Fan speed control reduces mechanical noise from cooling systems. Soundproof materials absorb and block unwanted sounds inside the cabinet. Electromagnetic noise control protects your signals from interference. When you use all three methods together, you create a quieter and more reliable environment for your equipment.

Tip: An integrated approach not only lowers noise but also improves system stability and extends equipment life.

Implementation Steps

You can follow these steps to integrate noise control solutions in your Telecom Power Systems:

Assess Current Noise Levels

Measure both acoustic and electromagnetic noise in your cabinet. Identify the main sources.Install Intelligent Fan Controls

Replace standard fans with models that support variable speed. Set up temperature sensors to automate fan speed.Apply Soundproof Materials

Choose materials based on the noise frequency and available space. Install acoustic foam, mass loaded vinyl, or metamaterials as needed.Enhance Electromagnetic Noise Control

Add EMI/EMC filters and ferrite beads to power and signal lines. Use shielding and organize cables to reduce interference.Test and Monitor

After installation, measure noise levels again. Adjust your setup if needed for the best results.

Step | Action Item | Expected Benefit |

|---|---|---|

Assess | Measure noise sources | Target solutions effectively |

Fan Controls | Install intelligent fans and sensors | Lower mechanical noise |

Soundproofing | Add acoustic materials | Block and absorb sound |

EMI Control | Use filters, beads, and shielding | Reduce electromagnetic noise |

Test & Monitor | Re-measure and adjust | Ensure optimal performance |

You can repeat this process as your system changes or grows. Regular reviews help you maintain a quiet and efficient cabinet.

Case Studies

Real-World Results

You can see the benefits of noise control strategies in action by looking at real-world examples. One telecom facility in Texas upgraded its cooling system by installing intelligent fan speed controls and soundproof materials. After the upgrade, staff measured a 15 dB reduction in cabinet noise. Employees reported a quieter workspace and fewer distractions. Another site in Germany used EMI filters and improved cable management. The team noticed fewer signal errors and more stable network performance.

A third example comes from a data center in Singapore. The team combined acoustic foam panels with variable-speed fans. They recorded a drop in both noise and equipment temperature. The facility also saw lower energy bills because the fans ran only when needed.

These examples show that you can achieve quieter and more efficient Telecom Power Systems by using a mix of active and passive noise control methods.

Lessons Learned

You should keep several lessons in mind when you plan your own noise control project:

Always measure noise levels before and after making changes. This helps you see what works best.

Choose materials and components that match your cabinet’s needs. Not every solution fits every setup.

Regular maintenance keeps your noise control measures effective over time.

Avoid blocking airflow with soundproof materials. Good airflow is key for cooling.

Train your staff on proper installation and monitoring.

Common Pitfall | How to Avoid It |

|---|---|

Poor airflow | Leave space for ventilation |

Wrong material choice | Match material to noise type |

Skipped maintenance | Set regular inspection schedule |

Careful planning and ongoing checks help you get the most from your noise control efforts.

You can achieve optimal noise reduction in telecom power systems by combining intelligent fan speed adjustment, soundproof material selection, and electromagnetic noise control. Regular predictive maintenance, real-time monitoring, and environmental controls further boost reliability and efficiency.

Actionable Step | Impact |

|---|---|

Predictive maintenance | Reduces disruptions and improves efficiency |

Real-time monitoring | Cuts repair time and prevents failures |

Environmental controls | Extends equipment lifespan |

Use filtering and shielding to protect signal integrity.

Optimize PCB design and cable management for best results.

Evaluate your current setup and start implementing these strategies today for quieter, more reliable operations.

FAQ

What is the main cause of noise in Telecom Power Systems?

You usually hear the most noise from cooling fans. These fans create both mechanical and airflow noise. Electromagnetic interference from cables and power lines can also add to the overall noise in Telecom Power Systems.

How do intelligent fan speed controls help reduce noise?

Intelligent fan speed controls adjust the fan speed based on temperature. You get less noise when the system does not need full cooling. This method also helps extend the life of your equipment in Telecom Power Systems.

Which soundproof materials work best for Telecom Power Systems?

You can use mass loaded vinyl, acoustic foam, and specialized server racks. These materials block or absorb sound. Choose the right material based on the noise frequency and available space in your Telecom Power Systems.

Why is electromagnetic noise control important in Telecom Power Systems?

Electromagnetic noise can disrupt signals and cause errors. You protect your equipment and maintain signal quality by using EMI filters, ferrite beads, and good cable management in Telecom Power Systems.

How often should you check noise control measures in Telecom Power Systems?

You should inspect noise control solutions every few months. Regular checks help you find worn materials or faulty fans. This keeps your Telecom Power Systems running quietly and efficiently.

See Also

Exploring Various Cooling Techniques for Telecom Cabinet Efficiency

Selecting Optimal Cooling Solutions for ESTEL Telecom Cabinets

Effective Strategies for Reducing Noise in Server Enclosures

Ensuring Consistent Power Supply for Telecom Cabinet Operations

Outdoor Communication Solutions with Specialized Telecom Cabinet Air Conditioning

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA