Shock Resistance Design for Telecom Cabinet Power Systems: Mechanical Shock Protection During Transportation & Installation

You face real challenges when you move or install Telecom Power Systems. Mechanical shock can damage sensitive components and disrupt service. Even a minor impact may cause hidden faults or shorten equipment life. You must protect your systems from vibration and sudden jolts. Failing to address shock risks leads to costly repairs and downtime. Focus on strong design and careful validation to keep your equipment reliable.

Key Takeaways

Mechanical shock can damage telecom equipment during transport. Always inspect cabinets for signs of shock damage after transportation to prevent costly downtime.

Strong structural design is essential for shock protection. Use reinforced frames and select materials based on the environment to enhance durability.

Choose components with proven shock resistance. Secure sensitive parts properly and avoid placing fragile components near cabinet walls to minimize risk.

Effective mounting and isolation techniques reduce shock transmission. Use shock-absorbing mounts and space equipment to protect against impacts.

Regular testing and adherence to industry standards ensure reliability. Document test results to identify weak points and improve future designs.

Importance of Shock Protection

Transportation and Installation Risks

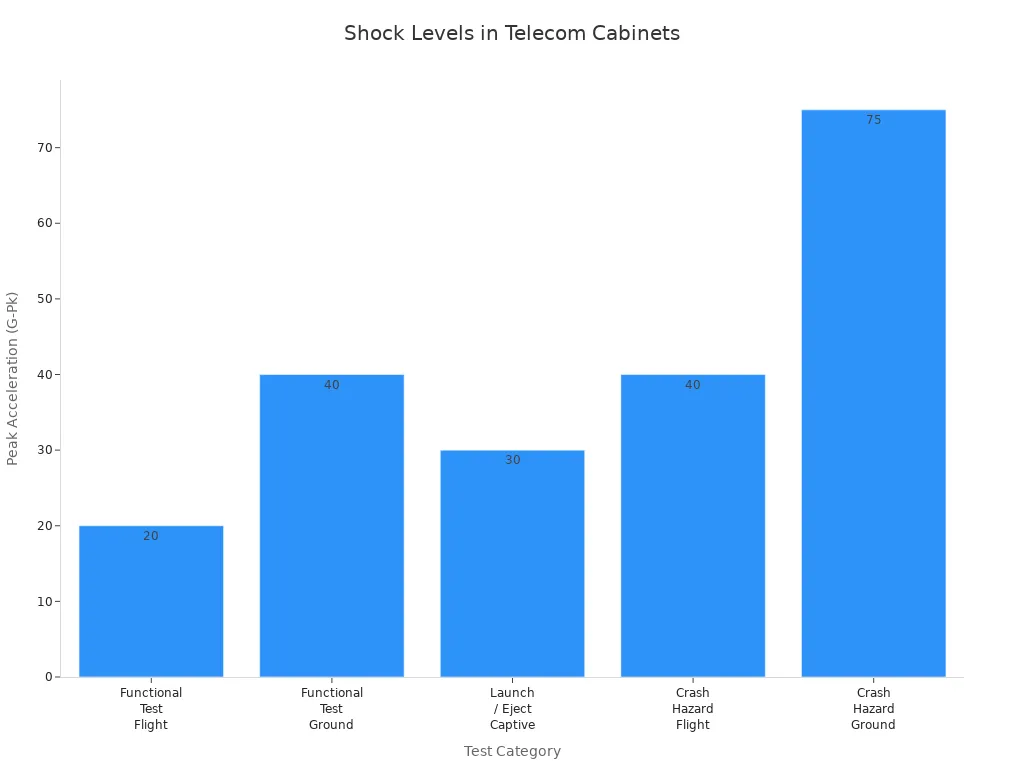

You must consider the risks your equipment faces during shipping and installation. Telecom cabinets often experience sudden jolts and vibrations that can damage sensitive electronics. Method 516 of MIL-STD-810 shows that transportation environments cause repetitive shock loads. These shocks usually have low amplitude but occur frequently, especially when moving cabinets by ground vehicles. You need to understand the typical shock levels to design effective protection.

Test Category | Peak Acceleration (G-Pk) |

|---|---|

Functional Test for Flight Equipment | 20 |

Functional Test for Ground Equipment | 40 |

Launch / Eject During Captive Carry | 30 |

Crash Hazard Shock Test for Flight Equipment | 40 |

Crash Hazard Shock Test for Ground Equipment | 75 |

You see that ground equipment can face peak accelerations up to 75 G during crash hazard tests. Even routine handling can expose cabinets to significant forces. If you do not address these risks, you may encounter hidden faults or immediate failures.

Tip: Always inspect cabinets for signs of shock damage after transportation. Early detection helps prevent costly downtime.

System Reliability

You want your Telecom Power Systems to deliver consistent performance. Shock protection plays a key role in maintaining reliability. Without proper shielding, you risk service disruptions and expensive repairs. Surge protection is necessary to avoid outages caused by power surges, lightning strikes, or internal load fluctuations.

Surge protection devices (SPDs) help reduce the risk of failures, especially for AC power.

Environmental shielding keeps your infrastructure safe from external threats.

Cabinets with integrated surge protection maintain network uptime and lower maintenance costs.

You prevent catastrophic failures and financial losses by investing in robust shock and surge protection.

You ensure your systems stay online and your customers remain satisfied. Reliable protection means fewer interruptions and lower long-term costs.

Design Strategies for Telecom Power Systems

Structural Design

You need strong structural design to protect Telecom Power Systems from mechanical shock. Cabinets must withstand vibration, impact, and harsh environments. You should reinforce the battery support frame so it resists damage from repeated jolts. The enclosure protection level for the battery compartment should reach IP44. This rating keeps dust and water out, which helps maintain shock resistance.

Feature | Description |

|---|---|

Battery Support Frame | Must have sufficient strength to withstand damage from vibration. |

Enclosure Protection Level | Required to reach IP44 for battery compartment to enhance shock resistance. |

Impact Resistance | Reinforced construction guards against accidental damage and vandalism. |

Vibration Resistance | Cabinets need to be designed to resist vibrations for stable operation. |

Corrosion Resistance | Essential for maintaining integrity in various environments. |

Dustproof and Waterproof | Protects internal components from environmental damage. |

You should select materials that match your environment and application. Metal cabinets offer strength and durability. They protect against physical damage and weather. Plastic cabinets work well indoors and resist corrosion. Composite materials provide high strength and resist UV radiation and chemicals. You can use them in harsh conditions or eco-friendly projects.

Material Type | Advantages | Applications |

|---|---|---|

Metal | Strength, durability, excellent protection against physical damage and environmental factors | Outdoor applications, areas prone to vandalism or harsh weather |

Plastic | Lightweight, cost-effective, resistant to corrosion | Indoor settings, regions with minimal corrosive factors |

Composite | High strength, lightweight, resistant to corrosion, UV radiation, and chemical exposure | Harsh environmental conditions, eco-friendly applications |

Tip: Choose cabinet materials based on your installation site. Outdoor locations need metal or composite for maximum protection.

Component Selection

You must pay close attention to the components inside Telecom Power Systems. Some parts are more vulnerable to mechanical shock. Electrolytic capacitors can fail if exposed to vibration. Microelectromechanical systems (MEMS) may stop working after a strong impact. You should select components with proven shock resistance and secure them properly.

Component Type | Vulnerability Description |

|---|---|

Electrolytic Capacitors | Susceptible to vibrational forces, leading to potential failures. |

Microelectromechanical Systems | Various failure modes due to mechanical impacts, including stiction and external impulses affecting functionality. |

You can use shock-absorbing mounts or potting compounds to protect sensitive electronics. Always check manufacturer specifications for shock ratings. You should avoid placing fragile components near cabinet walls or mounting points.

Note: Secure all connectors and cables to prevent movement during transport. Loose connections can cause intermittent faults.

Mounting and Isolation

You need effective mounting and isolation techniques to reduce shock transmission. Wire rope isolators and other shock isolation systems help protect Telecom Power Systems during transport and installation. These devices absorb and dissipate energy from impacts and vibrations.

Increased equipment longevity: Reduces shock effects, boosting longevity.

Improved efficiency: Minimizes harmful forces, allowing optimal operation.

Enhanced precision: Protects sensitive equipment calibration and measurement accuracy.

Elevated safety in transport: Mitigates shock effects, enhancing safety.

Reduced costs: Fewer replacements and decreased maintenance costs.

Boosted productivity: Maintains operations and maximizes output.

You should space equipment inside the cabinet to avoid direct contact between components. Use rubber grommets, foam pads, or spring mounts for extra isolation. Always follow best practices for mounting heavy items at the bottom of the cabinet. This lowers the center of gravity and reduces the risk of tipping.

Callout: Test your mounting and isolation systems before deployment. Simulate transport conditions to confirm shock protection.

Damping and Insulation Methods

Damping Materials

You need to select the right damping materials to protect your Telecom Power Systems from shock and vibration. Damping materials absorb energy and reduce the force that reaches sensitive components. Rubber stands out as a top choice because it offers a loss factor between 0.05 and 2. This means rubber can absorb more shock compared to metals like aluminum or steel, which have much lower loss factors.

Material | Loss Factor, η |

|---|---|

Aluminum | 0.0001–0.02 |

Concrete | 0.02–0.05 |

Copper | 0.001–0.05 |

Glass | 0.0001–0.005 |

Rubber | 0.05–2 |

Steel | 0.0001–0.01 |

You can use elastomer mounts to isolate equipment inside the cabinet. These mounts usually provide damping values around 0.1 to 0.15%. If you add cables, the damping coefficient can increase from 1% to 3%. More cables mean more energy absorption, which helps protect your system during transport.

Elastomer mounts: Damping values typically range from 0.1 to 0.15%.

Damping coefficient without cables: 1%

Damping coefficient with twenty cables: 3%

Tip: Place damping materials between the cabinet frame and internal components. This setup reduces the risk of damage from sudden impacts.

Insulation Performance

You must also focus on insulation performance to keep your Telecom Power Systems safe. Insulation prevents electrical faults and shields components from environmental hazards. Good insulation materials block moisture, dust, and temperature changes. Rubber and foam pads work well because they combine electrical insulation with shock absorption.

You should check the insulation rating before installation. High-quality insulation keeps your system running even in harsh conditions. Always inspect insulation for cracks or wear after transportation. Damaged insulation can lead to short circuits or equipment failure.

Note: Regular maintenance of insulation materials ensures long-term reliability and safety for your power systems.

Testing and Standards for Telecom Power Systems

Shock Testing Methods

You need to verify that your equipment can withstand real-world shocks before deployment. Shock testing methods help you simulate the forces Telecom Power Systems face during transportation and installation. You can use several approaches to evaluate durability and resilience.

Testing Method | Description |

|---|---|

Pyrotechnics | Simulates pyro-shock to test device resilience against explosive forces. |

Drop Testing | Involves dropping the device from a height to assess its durability under impact. |

Drop Towers | Utilizes controlled drop mechanisms to induce mechanical shock. |

Air Gun Generated Hydroshock | Creates shock waves to evaluate the device's response to sudden pressure changes. |

Free-Fall | Tests the device's ability to withstand free-fall impacts. |

Variable Force Test Techniques | Applies varying forces to simulate different shock scenarios. |

Temperature Alteration | Rapidly changes temperatures during testing to assess performance under thermal stress. |

You should also consider advanced techniques like the shock response spectrum (SRS). SRS helps you understand how your cabinet responds to different shock frequencies and amplitudes. Vibration and shock reproduction technology allow you to recreate actual transport conditions in the lab. These tests give you confidence that your system will perform reliably in the field.

Tip: Always document your test results. Detailed records help you identify weak points and improve future designs.

Industry Standards

You must follow industry standards to ensure safety and reliability. Standards provide clear guidelines for shock protection and help you meet regulatory requirements. The most relevant standards for Telecom Power Systems include IEC and NEBS specifications.

Standard | Description |

|---|---|

IEC 60950-1 Standard | Specifies grounding requirements for cabinets to prevent electric shock and equipment damage. |

NEBS GR-63-CORE Standard | Addresses seismic performance requirements for cabinets in earthquake-prone areas. |

Testing standards set the minimum requirements for shock resistance. You need to perform seismic testing to simulate earth movements and verify that your cabinets can withstand specific deformations. Shock and vibration testing ensures your equipment can endure typical vibrations found in vehicles or near industrial machinery.

Testing Standard | Description |

|---|---|

Seismic Testing | Simulates earth movements during a seismic event, requiring cabinets to withstand specific deformations and movements. |

Shock and Vibration Testing | Simulates conditions in mobile applications, ensuring cabinets can endure typical vibrations found in vehicles or near industrial equipment. |

You should build your cabinets with heavy-duty construction. Use back stiffeners and cross-bracing for stability. Double-walled construction adds strength. Vibration-resistant hardware and thicker gauge steel increase durability.

Heavy-duty construction prevents bending.

Back stiffeners and cross-bracing improve stability.

Double-walled construction adds strength.

Vibration-resistant hardware and thicker gauge steel increase durability.

You may also need to meet military standards for certain applications:

MIL-S-901D (Navy) – High impact shock testing for shipboard machinery and equipment.

MIL-STD-810F – Environmental shock and vibration testing.

MIL-STD-167 – Shipboard vibration testing.

Note: Always check which standards apply to your installation site. Compliance ensures safety and long-term reliability.

Grounding Resistance

You must pay attention to grounding resistance when designing shock protection. Low resistance to ground helps you redirect faults, lightning strikes, and surges quickly. This minimizes potential damage and improves safety in Telecom Power Systems.

Low ground resistance ensures fast diversion of surges and faults.

Effective grounding reduces the risk of electrical shocks and fire hazards.

Ground resistance affects how much and how quickly a surge can be diverted to the ground.

Overvoltage protectors work best with a low-resistance path for dissipating transient voltages.

High grounding resistance increases the activation level for protectors, which is less effective for shock protection.

Recommended values for grounding resistance vary by standard. You should aim for less than 5 ohms for most applications. Sensitive electronics require even lower resistance.

Source | Recommended Ground Resistance Value |

|---|---|

NFPA and IEEE | 5 ohms or less |

NEC | Less than 5 ohms |

IEEE 42 | 0.5 to 5 ohms |

General Recommendation | Less than 5 ohms |

Sensitive Electronics | Less than 1 ohm |

Callout: Test your grounding system regularly. Proper grounding protects your equipment and keeps your installation safe.

Optimization and Real-World Examples

Design Optimization

You can improve shock resistance in telecom cabinet power systems by using targeted optimization techniques. Start by focusing on thermal management. Heat can weaken components and cause failures. You should install cooling solutions like air conditioners or heat exchangers to keep temperatures stable. These systems help prevent heat-induced damage and extend the life of your equipment.

Environmental protection also plays a key role. Seals and filters block moisture and dust from entering the cabinet. This keeps sensitive electronics safe and reduces the risk of corrosion or short circuits. You should check seals regularly and replace them if you see any wear.

Consider these steps to optimize your cabinet design:

Use reinforced frames and vibration-resistant hardware.

Place heavy components at the bottom for better stability.

Add shock-absorbing mounts and damping materials.

Install cooling systems to control temperature.

Apply seals and filters to protect against contaminants.

Tip: Regular inspections and maintenance help you catch problems early and keep your system running smoothly.

Optimization Technique | Benefit |

|---|---|

Thermal Management | Prevents heat-related failures |

Environmental Protection | Shields from moisture and dust |

Reinforced Structure | Improves shock resistance |

Damping Materials | Absorbs impact energy |

Case Studies

You can learn from real-world examples of shock-resistant telecom cabinet designs. One telecom provider upgraded its outdoor cabinets by adding wire rope isolators and reinforced steel frames. After these changes, the cabinets survived multiple transport cycles without damage. Another company installed heat exchangers and high-quality seals in its cabinets. These upgrades reduced downtime caused by overheating and moisture.

A third example comes from a data center that used spring mounts and foam pads to isolate sensitive power modules. The equipment continued to operate reliably even after accidental drops during installation. These cases show that you can achieve better reliability and longer equipment life by applying proven optimization strategies.

Note: You should study successful projects and adapt their solutions to fit your own needs. This approach helps you avoid common mistakes and improve your shock protection plan.

You can design shock-resistant telecom cabinet power systems by following these key steps:

Assess your site with digital twin models and aerial imagery.

Centralize data for better collaboration.

Select sensors suited to your environment.

Test and validate systems after installation.

Monitor health with inspections and software updates.

Train staff to spot early warning signs.

Use redundant power and cooling systems.

High-rated enclosures and proper thermal management protect against dust, moisture, and overheating, helping you maintain long-term reliability.

Installation Guideline | Explanation |

|---|---|

Ventilation slots dissipate heat from equipment. | |

Environmental Considerations | Choose cabinets for local risks like earthquakes. |

Easy Access | Design for simple maintenance and upgrades. |

Cable Management | Organize cables for clean and easy repairs. |

You should review IEC standards and consider environmental conditions to ensure safe, reliable operation.

FAQ

What is the main cause of shock damage in telecom cabinets?

You often see shock damage during transportation or installation. Sudden impacts, drops, or vibrations can harm sensitive components. You must secure equipment and use shock-absorbing materials to prevent failures.

How do you test shock resistance in telecom power systems?

You use drop tests, vibration tables, and shock response spectrum (SRS) analysis. These methods help you check if your cabinet can survive real-world impacts. Always document your results for future improvements.

Which materials work best for shock damping?

Rubber and elastomers provide excellent shock absorption. You can also use foam pads or wire rope isolators. These materials reduce the force that reaches your equipment.

Tip: Place damping materials between the cabinet frame and internal components for better protection.

Why is grounding resistance important for shock protection?

Low grounding resistance lets you quickly divert electrical surges and faults. This protects your equipment from damage and reduces fire risk. You should aim for less than 5 ohms in most cases.

See Also

Strategies for Safeguarding Equipment Using Outdoor Telecom Cabinets

Ways to Guarantee Consistent Power Supply in Telecom Cabinets

Essential Material Specifications for Outdoor Telecom Cabinets

New Developments Shaping Outdoor Telecom Cabinet Designs

Design Guidelines for ESTEL Telecommunication Cabinet Structures

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA