What temperature sensor helps avoid costly telecom cabinet failures

The most effective temperature sensor for outdoor telecom cabinets uses multi-point, high-accuracy digital sensing. This type measures temperatures from -40°C to +75°C with a precise 0.1°C resolution and ±0.3°C accuracy, helping prevent overheating and unnecessary energy use.

Value / Description | |

|---|---|

Number of Temperature Sensors | 6 temperature sensors + 3 differential temperature sensors per cabinet |

Temperature Measurement Range | -40°C to +75°C |

Temperature Resolution | 0.1°C increments |

Temperature Accuracy | ±0.3°C at critical points (-40°C, +25°C, +75°C) |

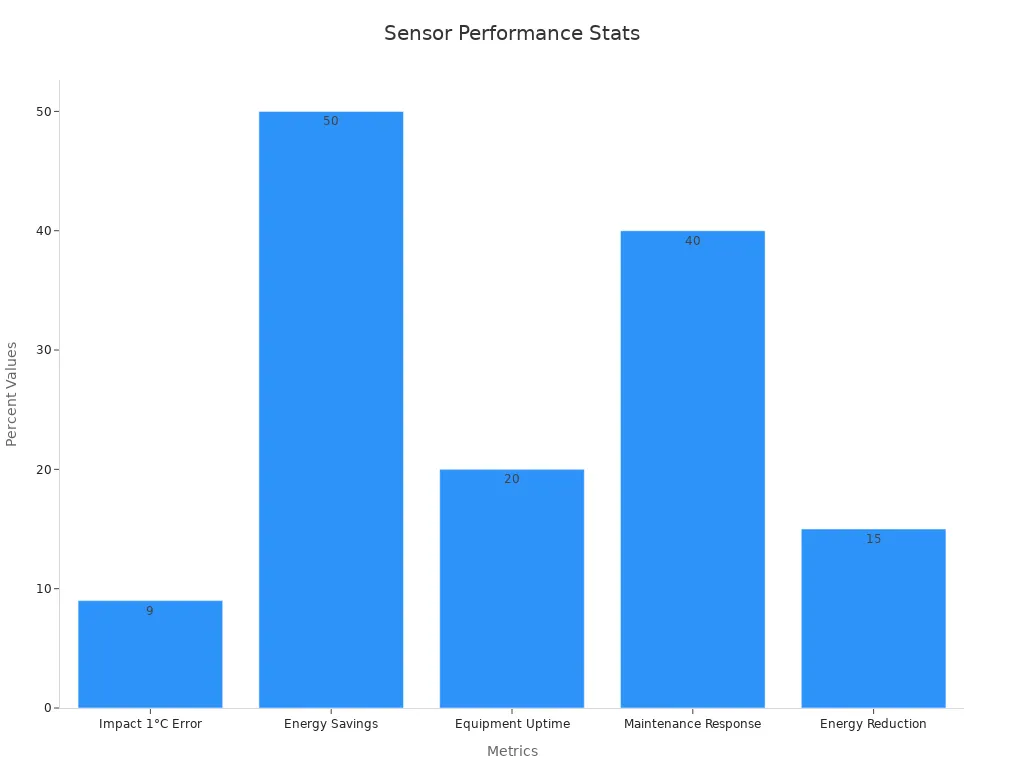

Impact of 1°C Measurement Error | Up to 9% increase in energy consumption |

Energy Savings from Advanced Cooling | Over 50% reduction in air conditioner power consumption |

Equipment Uptime Improvement | 20% increase with intelligent monitoring systems |

Maintenance Response Improvement | 40% faster response times using remote monitoring |

Energy Consumption Reduction | 15% reduction with intelligent PDUs |

By combining temperature and humidity monitoring, telecom operators gain a complete view of cabinet conditions. Real-time alerts and remote monitoring systems provide a rapid response to abnormal changes, as seen in a field study where 378 alarms received action within minutes and downtime decreased by 15%. These features reduce failures, improve uptime, and lower maintenance costs.

Key Takeaways

Use multi-point, high-accuracy temperature sensors to detect temperature changes precisely and prevent overheating in telecom cabinets.

Combine temperature and humidity monitoring to spot risks like moisture and heat, reducing equipment failures and lowering maintenance costs.

Place sensors near heat sources, air intakes, and exhausts inside cabinets to capture accurate environmental data and avoid false readings.

Follow regular maintenance routines including cleaning and calibration to keep sensors reliable and extend their lifespan.

Real-time alerts and remote monitoring help operators respond quickly to problems, improving uptime and saving energy.

Temperature Sensor Features

Accuracy

A temperature sensor must deliver precise readings to protect telecom equipment. High accuracy ensures that cooling systems respond only when needed, reducing unnecessary energy use. Many advanced sensors achieve measurement accuracy as fine as 0.001°C in controlled environments. In real-world telecom cabinets, systems like RDTS reach an average accuracy of ±0.63°C, even in areas with rapid temperature changes.

Benchmark / Metric | Description / Value |

|---|---|

Temperature measurement accuracy | Precision up to 0.001°C in labs; ±0.63°C in telecom cabinet applications |

Calibration standards | Calibrated against ITS-90 fixed points (13.8 K to 1234.93 K) |

Resistance measurement uncertainty | 5 µK to 1 mK using low-frequency resistance bridges |

Statistical validation | Correlation coefficient of 0.98 between estimated and experimental deviations |

Sensors use advanced electronic circuits and sealed cavities filled with insulating oil to reduce thermal drift and noise. Regular calibration against international standards ensures reliable performance. In extreme conditions, experts evaluate sensor accuracy by tracking the percentage of measurement errors that exceed 20%. This metric helps operators identify sensors that may cause costly failures.

Durability

Telecom cabinets face harsh outdoor conditions. A temperature sensor must withstand thermal cycling, vibration, humidity, corrosion, and mechanical shock. Manufacturers select materials with high thermal diffusivity and resistance to shock and fatigue.

Accelerated aging and life testing simulate years of exposure in a short time.

Highly Accelerated Life Test (HALT) chambers apply rapid temperature transitions and vibration to reveal design weaknesses.

Salt spray and corrosion tests check the resilience of protective coatings and sensor materials.

Proper selection and testing of components—such as the sheath, leads, sensing element, and potting—extend the sensor’s lifespan. Qualification testing and similarity analysis confirm that each sensor meets mission-critical requirements.

Response Time

Fast response time is essential for a temperature sensor in telecom cabinets. Quick detection of temperature spikes allows cooling systems to react before equipment overheats.

Note: Key performance metrics include response time, accuracy, and reliability. These factors work together to ensure that sensors provide timely alerts and prevent equipment damage.

Sensor system design often includes multiple sensors for environment control. Advanced electronic circuits and PID control algorithms help reduce noise and improve response speed. Oversampling and statistical methods further enhance accuracy and precision.

Environmental Protection

Outdoor telecom cabinets expose sensors to moisture, dust, UV radiation, and extreme temperatures. Environmental protection features keep sensors working reliably over time.

Protection Feature | Description |

|---|---|

IP Rating | High IP ratings (e.g., IP65 or above) guard against dust and water |

UV Exposure Testing | Simulates solar radiation to assess long-term degradation |

Humidity Testing | Evaluates performance under moisture and temperature variations |

Thermal Shock Testing | Detects failures from rapid temperature changes |

Vibration and mechanical shock tests ensure sensors survive both operation and transport. Air pressure and altitude tests validate sensor function in various environments. These protective measures help maintain accurate readings and prevent costly telecom cabinet failures.

Temperature and Humidity Monitoring

Combined Benefits

Integrating temperature and humidity sensors in outdoor telecom cabinets provides a complete picture of environmental conditions. These sensors work together to detect not only heat but also moisture, which can cause corrosion or short circuits. Operators gain the ability to spot risks before they lead to equipment damage. Real-time monitoring allows teams to respond quickly to changes, reducing the chance of unexpected failures.

The following table highlights the cost-saving and reliability benefits of combining temperature and humidity monitoring:

Cost Saving or Benefit Area | Reported Impact or Percentage |

|---|---|

Energy use reduction | Up to 30% |

Downtime reduction | 15% to 25% |

Maintenance cost savings | Up to 40% over reactive maintenance |

Cost savings from ESTEL solutions | Up to 20% |

Power-related outage reduction | Up to 40% |

These numbers show that integrated monitoring leads to lower energy bills, fewer outages, and less money spent on emergency repairs. Predictive maintenance becomes possible, as sensor data helps teams plan service before problems grow.

Failure Prevention

Combined temperature and humidity monitoring prevents many common failures in telecom cabinets. For example, a sudden rise in humidity can signal a door left open during rain, which may lead to water damage. A temperature sensor alone would not catch this risk. In another case, a spike in temperature paired with high humidity might indicate a failing air conditioner, allowing technicians to fix the issue before equipment overheats.

Operators have reported that real-time alerts from these sensors helped them act within minutes, reducing downtime by up to 25%. Early detection of environmental threats means less equipment replacement and longer service life for critical components. By using both types of sensors, telecom companies protect their investments and keep networks running smoothly.

Installation and Maintenance

Placement

Proper sensor placement inside outdoor telecom cabinets ensures accurate environmental monitoring. Technicians should install sensors at multiple points to capture temperature and humidity variations. Placing sensors near heat-generating equipment, such as power supplies and processors, helps detect localized hotspots. Installing one sensor close to the air intake and another near the exhaust provides a clear view of airflow efficiency. Avoid mounting sensors directly in the path of cooling fans, as this can cause false readings. Technicians should also keep sensors away from doors and vents to prevent exposure to external weather conditions.

Tip: Use a placement checklist to confirm all critical areas have coverage. This approach helps identify risks early and supports consistent monitoring.

Maintenance

Routine maintenance keeps sensors reliable and extends their lifespan. Operators should follow a structured schedule for inspections, cleaning, and calibration. The following best practices support optimal performance:

Perform monthly inspections and diagnostics to catch anomalies, such as irregular voltage or unexpected readings.

Clean sensors regularly to prevent dust and debris buildup, which can affect accuracy.

Calibrate monitoring components during preventive maintenance to ensure alarms and systems work correctly.

Maintain detailed logs of inspection and calibration results to track trends and spot inconsistencies.

Use comprehensive checklists to identify damage, loose connections, or environmental wear.

Troubleshoot issues during routine checks to resolve problems before they cause failures.

Facilities that follow preventive maintenance plans see reduced downtime, lower repair costs, and longer equipment life. For example, a major telecom operator who implemented predictive maintenance across thousands of sites achieved a 35% reduction in network downtime and saved millions in annual maintenance costs. Remote monitoring and real-time diagnostics further improve efficiency by reducing unnecessary service visits and optimizing personnel workload.

Note: Consistent maintenance schedules, including cleaning, calibration, and component replacement, contribute to long-term reliability and minimize unexpected downtime.

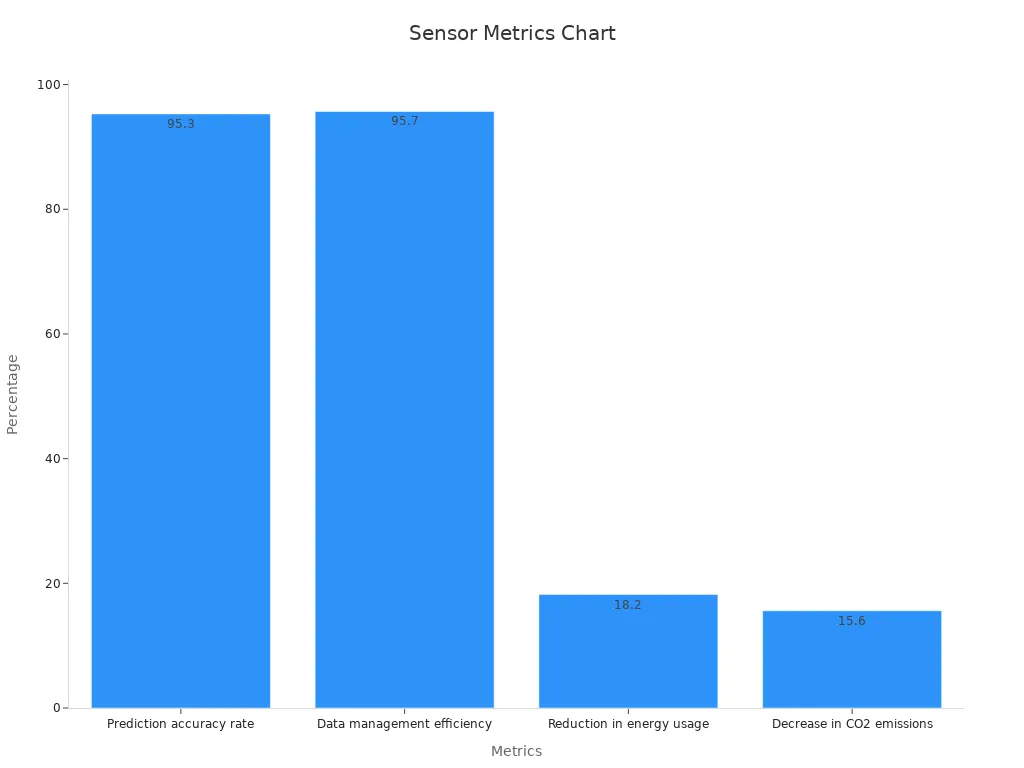

A multi-point, high-accuracy temperature sensor with integrated humidity monitoring offers the best protection for outdoor telecom cabinets. Operators benefit from real-time alerts, predictive analytics, and reduced site visits, as shown by a 95.3% prediction accuracy rate and an 18.2% drop in energy use.

To maximize reliability, teams should:

Select sensors with fast response and customizable alerts.

Install sensors at critical points inside cabinets.

Maintain regular cleaning and calibration schedules.

Combining temperature and humidity monitoring prevents costly failures and supports long-term network performance.

FAQ

What makes a temperature sensor suitable for outdoor telecom cabinets?

A suitable sensor resists moisture, dust, and UV rays. It provides accurate readings across wide temperature ranges. High IP ratings and robust materials ensure long-term reliability in harsh environments.

What is the ideal placement for temperature sensors inside a cabinet?

Technicians place sensors near heat sources, air intakes, and exhausts. This setup detects hotspots and airflow issues. Avoiding direct airflow from fans prevents false readings.

What maintenance does a temperature and humidity sensor require?

Regular cleaning and calibration keep sensors accurate. Technicians inspect for dust, corrosion, or loose connections. Scheduled checks help prevent unexpected failures.

What benefits do real-time alerts offer for telecom operators?

Real-time alerts notify teams of abnormal temperature or humidity changes. Operators respond quickly, reducing downtime and preventing equipment damage. This proactive approach saves costs and improves network reliability.

See Also

Tips For Maintaining Ideal Temperatures In Outdoor Telecom Cabinets

Exploring Various Cooling Techniques And Their Uses In Telecom Cabinets

Selecting The Most Effective Cooling Solution For ESTEL Telecom Cabinets

Strategies To Achieve Effective Monitoring Of Outdoor Telecom Cabinets

Understanding Temperature Compensation In Power Supplies For Telecom Cabinets

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA