Understanding What a Rectifier Is and How It Works

A rectifier is an essential device in electrical systems. Its primary function is to convert alternating current (AC) into direct current (DC), which is necessary for powering most electronic devices. This process involves using components like diodes to allow current to flow in only one direction, creating a steady DC output.

Rectifiers play a crucial role in improving energy efficiency and reducing costs. For instance:

Custom rectifiers can save businesses thousands of dollars annually by optimizing energy output.

In railways, rectifiers enhance energy recovery during braking by up to 30%, promoting sustainability.

Properly designed rectifiers lower initial costs and improve long-term performance.

Whether in consumer electronics or industrial applications, rectifiers ensure reliable and efficient power delivery.

Key Takeaways

Rectifiers change alternating current (AC) into direct current (DC). This is needed to power most electronic devices.

Using rectifiers makes energy use better and saves money. Businesses can save thousands of dollars each year.

Diodes are key parts of rectifiers. They let current flow one way and keep the DC output steady.

There are different rectifiers, like half-wave and full-wave. Full-wave rectifiers work better and are more efficient.

Taking care of rectifiers stops them from overheating or wasting energy. This helps them last longer and work well.

What Is a Rectifier?

Definition and Function

A rectifier is a device that converts alternating current (AC) into direct current (DC). This process, known as rectification, is essential because most electronic devices and systems require DC to operate. AC alternates its direction periodically, while DC flows in a single, steady direction. By transforming AC into DC, rectifiers ensure that electrical energy can power devices like smartphones, laptops, and industrial machinery.

The core component of a rectifier is the diode. Diodes allow current to flow in only one direction, blocking the reverse flow. This property makes them ideal for rectification. For example, in a bridge rectifier, four diodes work together to convert AC into a smoother DC output. The efficiency of this process depends on factors like the forward voltage drop of the diodes and the design of the rectifier circuit.

Rectifiers also include additional components, such as filter capacitors, to stabilize the DC output. These capacitors reduce the ripple effect, which is the fluctuation in voltage that occurs after rectification. A stable DC output is crucial for sensitive electronic devices that require consistent power.

Specification/Parameter | Description |

|---|---|

Main Function | Converts AC to DC through a bridge circuit of four diodes. |

Output Voltage | Average output voltage formula: V_out=(2V_m)/π - (4V_f)/π, where V_m is peak AC voltage. |

Filtering | Filter capacitors are used to smooth pulsating DC output for stability. |

Efficiency | The rectification process efficiency is influenced by the forward voltage drop of diodes (V_f). |

Importance in Electrical Systems

Rectifiers play a vital role in modern electrical systems. They are the backbone of power supply units, ensuring that devices receive the correct type of current. Without rectifiers, many of the technologies you use daily would not function.

In industrial applications, rectifiers are indispensable. They power electric motors, industrial robots, and other machinery that rely on DC. For instance, segment analysis shows that industries like robotics and electric motors are among the fastest-growing users of rectifiers. This highlights their importance in driving technological advancements.

Metric Type | Description |

|---|---|

Market Size | Comprehensive forecast of revenue growth for the Power Rectifiers industry from 2019 to 2031. |

Segment Analysis | Insights into fastest-growing segments like industrial robots and electric motors. |

Factors Affecting Market | Detailed analysis of drivers, opportunities, and challenges impacting the market. |

Rectifiers also contribute to energy efficiency. A full-wave rectifier, for example, has a maximum conversion ratio of approximately 81%, making it significantly more efficient than a half-wave rectifier. This efficiency reduces energy waste and lowers operational costs. In three-phase systems, rectifiers achieve even greater efficiency, making them ideal for large-scale industrial and telecommunications applications.

Metric | Half-Wave Rectifier | Full-Wave Rectifier | Three-Phase Full-Wave Rectifier |

|---|---|---|---|

Maximum Conversion Ratio (η) | ≈ 40.5% | ≈ 81.0% | Greater than full-wave rectifier |

Ripple Factor | Higher | Lower | Lowest |

By ensuring efficient energy conversion and stable power delivery, rectifiers support the functionality of countless devices and systems. Their role in electrical systems cannot be overstated.

How Rectifiers Work

AC to DC Conversion Process

The primary function of a rectifier is to convert alternating current (AC) into direct current (DC). AC flows in two directions, alternating between positive and negative cycles. However, most electronic devices require a steady flow of current in one direction, which is where rectifiers come into play.

The conversion process begins when AC enters the rectifier circuit. The rectifier uses diodes to block the negative half of the AC cycle, allowing only the positive half to pass through. This process is called half-wave rectification. In full-wave rectification, the circuit flips the negative half of the AC cycle into a positive one, resulting in a smoother DC output.

To further stabilize the DC output, rectifiers often include filter capacitors. These components store electrical energy and release it gradually, reducing voltage fluctuations. This ensures that the DC output remains consistent, which is crucial for powering sensitive devices like computers and medical equipment.

Role of Diodes in Rectification

Diodes are the heart of any rectifier. They act as one-way gates, allowing current to flow in only one direction. This unique property makes them ideal for converting AC to DC. When AC voltage is applied to a diode, it conducts during the positive half-cycle and blocks during the negative half-cycle.

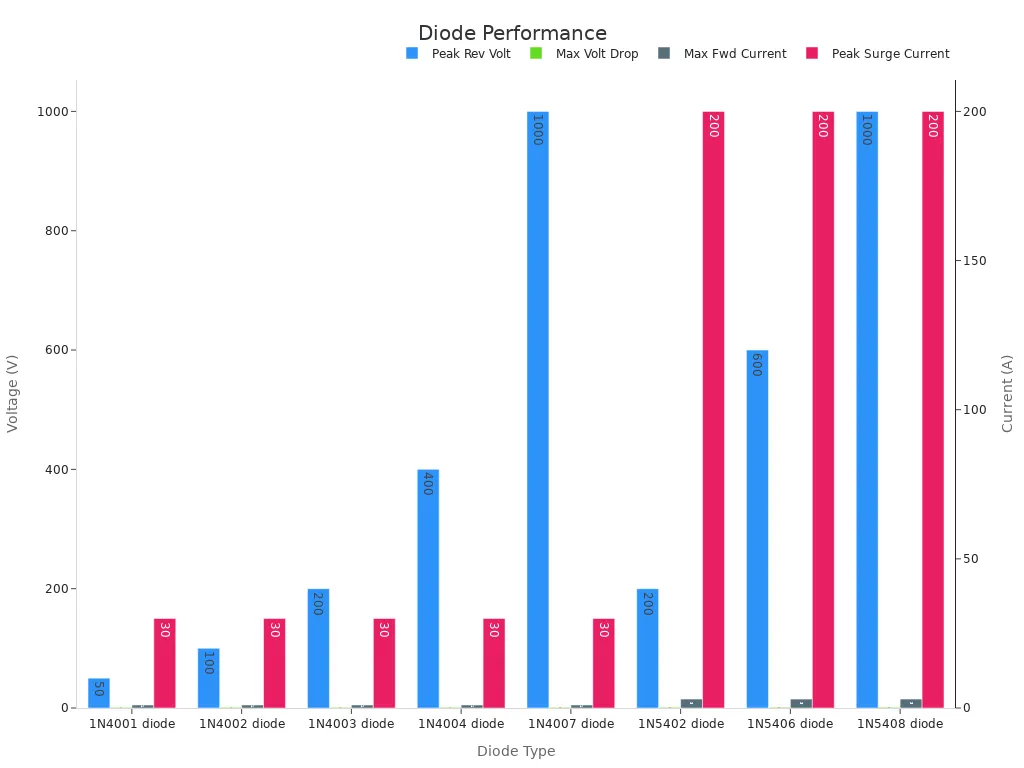

Different types of diodes are used in rectification circuits, each with specific performance characteristics. For example, the 1N4007 diode can handle a peak reverse voltage of 1000 volts, making it suitable for high-voltage applications. On the other hand, the 1N5408 diode supports a higher maximum forward current, making it ideal for circuits requiring more power.

Rectifier diode name | Peak reverse voltage (V) | Max. forward current (A) | Peak surge current (A) | Max voltage drop (V) |

|---|---|---|---|---|

1N4001 diode | 50 | 1 | 30 | 1.1 |

1N4002 diode | 100 | 1 | 30 | 1.1 |

1N4003 diode | 200 | 1 | 30 | 1.1 |

1N4004 diode | 400 | 1 | 30 | 1.1 |

1N4007 diode | 1000 | 1 | 30 | 1.1 |

1N5402 diode | 200 | 3 | 200 | 1.2 |

1N5406 diode | 600 | 3 | 200 | 1.2 |

1N5408 diode | 1000 | 3 | 200 | 1.2 |

The table above highlights the performance capacities of various diodes commonly used in rectification circuits. Choosing the right diode depends on the voltage and current requirements of your application.

Solid-State vs. Vacuum Tube Rectifiers

Rectifiers come in two main types: solid-state and vacuum tube. Solid-state rectifiers use semiconductor diodes, while vacuum tube rectifiers rely on electron flow within a vacuum.

Solid-state rectifiers are more common today due to their efficiency and durability. They are compact, require less maintenance, and can handle higher currents. For example, a solid-state rectifier can achieve a maximum conversion efficiency of up to 81% in a full-wave configuration.

Vacuum tube rectifiers, on the other hand, were widely used in older electronic devices. They operate by heating a cathode to release electrons, which then flow to an anode. While they are less efficient and bulkier than their solid-state counterparts, vacuum tube rectifiers are still valued in certain audio and radio equipment for their unique sound characteristics.

When choosing between the two, solid-state rectifiers are the better option for most modern applications. They offer superior performance, reliability, and energy efficiency, making them the preferred choice for powering today's electronic devices.

Types of Rectifiers

Rectifiers come in different types, each designed for specific applications. Understanding these types helps you choose the right one for your needs.

Half-Wave Rectifier

A half-wave rectifier is the simplest type. It uses a single diode to convert alternating current (AC) into direct current (DC). During the positive half of the AC cycle, the diode allows current to pass through. In the negative half, it blocks the current. This process results in a pulsating DC output.

Half-wave rectifiers are easy to build and cost-effective. However, they are not very efficient. They only use half of the AC cycle, which leads to higher energy loss. These rectifiers are suitable for low-power applications, such as small battery chargers or signal demodulation.

Feature | Half-Wave Rectifier |

|---|---|

Number of Diodes | 1 |

Efficiency | Low |

Applications | Low-power devices |

Tip: If you need a simple and affordable solution for basic tasks, a half-wave rectifier might be the right choice.

Full-Wave Rectifier

A full-wave rectifier improves efficiency by using both halves of the AC cycle. It requires either two diodes and a center-tapped transformer or four diodes in a bridge configuration. This design produces a smoother DC output compared to a half-wave rectifier.

Full-wave rectifiers are more efficient and reliable. They are commonly used in power supplies for household electronics, such as televisions and radios. The smoother output reduces the need for large filter capacitors, making the circuit more compact.

Feature | Full-Wave Rectifier |

|---|---|

Number of Diodes | 2 or 4 |

Efficiency | High |

Applications | Power supplies |

Bridge Rectifier

A bridge rectifier is a type of full-wave rectifier. It uses four diodes arranged in a bridge configuration. This design eliminates the need for a center-tapped transformer, making it more versatile. The bridge rectifier converts both halves of the AC cycle into DC, providing a steady output.

Bridge rectifiers are highly efficient and widely used in industrial and consumer electronics. They are ideal for applications requiring high power and reliability, such as motor drives and LED lighting systems.

Feature | Bridge Rectifier |

|---|---|

Number of Diodes | 4 |

Efficiency | Very High |

Applications | Industrial systems |

Note: If you need a robust and efficient solution for high-power applications, consider using a bridge rectifier.

Applications of Rectifiers

Power Supply Systems

Rectifiers are essential in power supply systems. They convert AC from the main power source into DC, which is required by most electronic devices. Modern power supply units (PSUs) have seen significant improvements in efficiency due to advancements in rectifier technology. For example:

In the early 2000s, server PSUs operated at just over 65% efficiency.

The introduction of the 80 Plus standard in 2004 raised this to over 80%.

Today, many PSUs achieve 92% efficiency under the 80 Plus Gold standard, with some reaching 94% under the Platinum standard.

Cutting-edge PSUs now aim for the Titanium standard, achieving over 96% efficiency.

These advancements reduce energy waste and lower operational costs, making rectifiers a critical component in sustainable power systems.

Consumer Electronics

In consumer electronics, rectifiers ensure devices receive the steady DC power they need to function. Smartphones, laptops, and televisions all rely on rectifiers within their power adapters. Without rectifiers, these devices would not operate reliably.

For example, when you charge your phone, the charger uses a rectifier to convert AC from the wall outlet into DC. This ensures your phone's battery charges safely and efficiently. Similarly, televisions use rectifiers to power their internal circuits, providing you with uninterrupted viewing experiences.

Industrial and Telecommunications Uses

Industries and telecommunications heavily depend on rectifiers for their operations. In industrial settings, rectifiers power electric motors, welding equipment, and robotic systems. These applications require high reliability and efficiency, which modern rectifiers provide.

In telecommunications, rectifiers play a vital role in powering base stations, data centers, and network equipment. They ensure uninterrupted communication by converting AC into DC for backup power systems. Data centers, for instance, use rectifiers in their PSUs to achieve peak efficiencies of over 97.5%, reducing energy consumption and operational costs.

Did you know? Rectifiers in telecommunications systems help maintain network stability during power outages by supporting battery backup systems.

Troubleshooting Rectifiers

Common Issues (e.g., overheating, inefficiency)

Rectifiers, like any electronic component, can encounter problems that affect their performance. Overheating is one of the most common issues. It occurs when the rectifier operates beyond its thermal limits, often due to excessive current or poor ventilation. Inefficiency is another frequent problem. This happens when the rectifier fails to convert AC to DC effectively, leading to energy losses and reduced output quality.

Other issues include electrical noise, which can disrupt sensitive devices, and component failure, such as damaged diodes or capacitors. These problems can compromise the reliability of your system. For example:

High-current rectifiers with outdated designs may experience up to 7.2% higher copper losses in transformers compared to modern diode-based rectifiers.

Inefficient rectifiers can lead to increased operational costs and reduced system lifespan.

Identifying these issues early is crucial to maintaining optimal performance.

Resolving Problems

You can address rectifier problems using effective troubleshooting techniques. Start with electrical continuity testing. This method ensures all connections are intact and internal circuits do not interfere with performance. Instant-off potential measurement is another useful technique. It evaluates rectifier performance by measuring voltage under specific conditions, such as peak-hold or manual current interruption.

Visual surveys are also essential. Inspect the rectifier and its associated systems for visible damage, such as burnt components or loose connections. The table below outlines these techniques:

Technique | Description |

|---|---|

Electrical Continuity Testing | Checks connections and ensures internal circuits do not affect test results. |

Instant-Off Potential Measurement | Measures voltage using methods like peak-hold and manual current interruption. |

Visual Surveys | Identifies visible issues with rectifiers and associated systems. |

By combining these methods, you can diagnose and resolve most rectifier issues efficiently.

Preventive Maintenance Tips

Preventive maintenance helps you avoid rectifier problems before they occur. Regularly clean the rectifier to remove dust and debris that can block airflow and cause overheating. Monitor the operating temperature to ensure it stays within safe limits. Use a thermal sensor if necessary.

Inspect the diodes and capacitors periodically for signs of wear or damage. Replace any faulty components immediately. Upgrading to modern rectifier designs, such as modular multi-cell technology, can also improve efficiency and reliability. These designs outperform traditional Thyristor-based solutions, reducing energy losses and equipment costs.

Tip: Schedule routine maintenance checks every six months to keep your rectifier in top condition. A little effort now can save you from costly repairs later.

By following these tips, you can extend the lifespan of your rectifier and ensure consistent performance.

Rectifiers are vital for converting AC to DC, ensuring your devices receive the power they need. You’ve learned about their types, how they work, and their importance in systems like power supplies and telecommunications. Their efficiency and reliability make them indispensable in modern technology.

Explore More: Dive deeper into rectifier designs and applications. Understanding these systems can help you make informed decisions for your projects or devices. Rectifiers power the world—now it’s your turn to harness their potential!

See More:

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA