What is an Enclosure Heat Exchanger and How It Works

An enclosure heat exchanger controls the temperature inside closed equipment boxes. It moves heat from inside to outside while keeping dirt out. This helps protect electronics or machines and keeps them safe to use.

Its performance is measured by something called heat transfer units (NTU). Higher NTU numbers mean it works better. For instance, an aluminum heat sink can lower heat by 0.083 °C/W on each side, making heat transfer effective. Keeping temperatures steady helps equipment last longer and avoids expensive repairs.

Key Takeaways

An enclosure heat exchanger cools equipment by moving heat outside. This stops overheating and protects delicate parts.

Picking the right heat exchanger saves energy and lowers costs. Choose ones with heat pipes and eco-friendly coolants.

Keeping temperatures steady helps machines last longer. Avoiding high heat prevents breakdowns and costly repairs.

Enclosure heat exchangers are easy to maintain. Most need little care and have features to run well.

There are different heat exchangers for various needs. Air-to-air, liquid-to-air, and NEMA-rated types fit different spaces and cooling jobs.

What is an Enclosure Heat Exchanger?

Definition and Function

An enclosure heat exchanger is a cooling tool for sealed boxes. It moves heat from inside to outside without letting in dust or water. This keeps electronics or machines safe from overheating and working well.

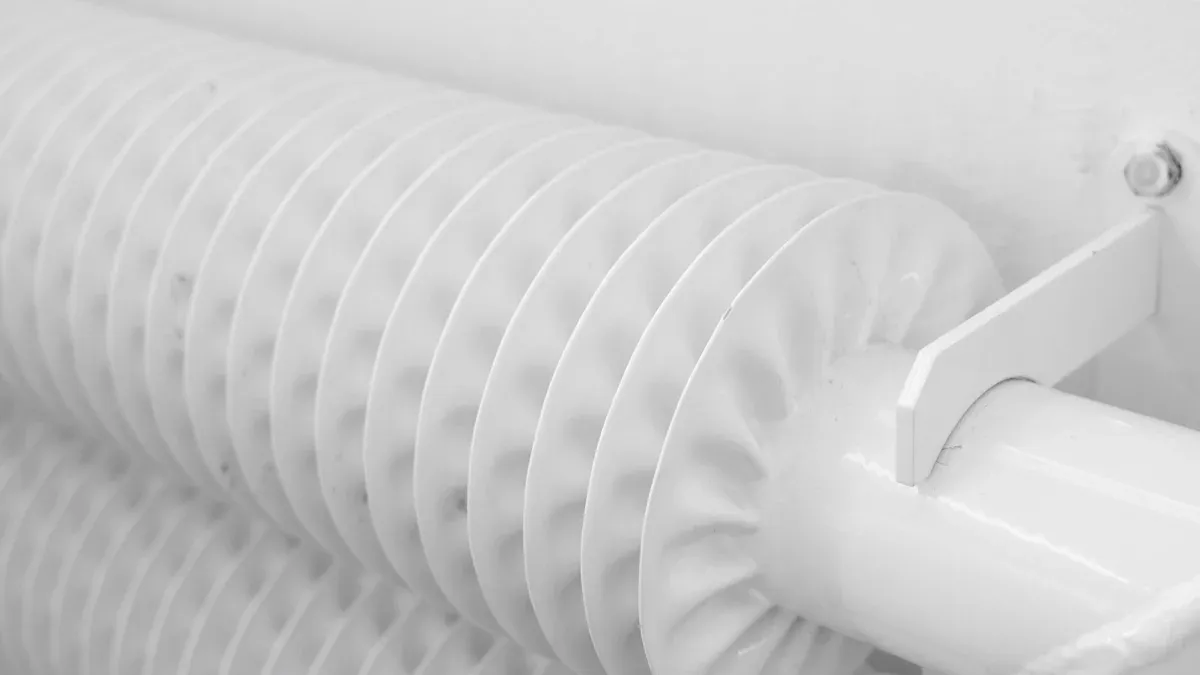

These devices use heat pipes to move heat quickly. They cool warm air and send it back inside, keeping the temperature steady. Whether for factory machines or electronic boxes, an enclosure heat exchanger protects your equipment and keeps it running smoothly.

Key Features and Components

Enclosure heat exchangers have parts that make them work better. Here are the main ones:

Feature/Component | Description |

|---|---|

Temperature Control | Stops overheating, keeping things running without problems. |

Energy Efficiency | Uses less energy, saving money on power bills. |

Eco-friendly Refrigerants | Helps the planet by reducing harm to the environment. |

Compressor | Presses refrigerant into hot gas to release heat. |

Evaporator Coil | Takes heat from inside, cooling the air. |

Condenser Coil | Pushes heat outside the box. |

Fans | Move air over coils to help cool faster. |

Filters | Catch dust to keep air clean. |

Condensate Management | Stops water damage with a drain pan. |

Durability | Strong materials last long in tough places. |

These parts work together to cool the box. For example, the evaporator coil cools the air inside, and the condenser coil sends heat out. Fans help air move, and filters keep dirt away. This teamwork makes the system reliable, even in hard conditions.

Tip: Pick an enclosure heat exchanger with the right cooling power and strength for your needs.

How Does an Enclosure Heat Exchanger Work?

Heat Transfer Mechanisms

Heat transfer helps an enclosure heat exchanger control temperatures. It uses heat pipe technology to move heat out of the box. Heat pipes are sealed tubes with a liquid inside. The liquid turns into gas when heated and back to liquid when cooled. This cycle moves heat without needing extra power.

Scientists study ways to make heat transfer better. Sathe et al. (2019) found that fin angles affect heat movement speed. Kamkari et al. (2014) showed natural airflow helps heat move faster. These studies help engineers design better systems for different needs.

Note: Picking the right heat exchanger design improves cooling for your equipment.

Closed-Loop System Explained

An enclosure heat exchanger often works as a closed-loop cooling system. This system keeps inside air separate from outside air. It stops dust and water from getting in.

Here’s how it works:

Warm air inside touches the evaporator coil, which absorbs heat.

Heat travels through pipes to the condenser coil.

The condenser coil sends heat outside the box.

Fans push cool air back inside, keeping the temperature steady.

This design is great for delicate machines like electronics. It cools well and protects parts from outside harm.

Maintaining Internal Temperatures

Keeping steady temperatures is key for equipment to last longer. Cooling units use sensors and eco-friendly refrigerants to do this. They adjust cooling based on how much heat the equipment makes.

Examples show why temperature control matters. Engineers improved a heat exchanger for a high-power electronics box. They used copper fins and pipes to lower thermal resistance to 0.044°C/W. This met strict cooling needs, kept equipment safe, and saved energy.

By keeping temperatures steady, heat exchangers stop overheating, reduce damage, and help equipment last longer.

Benefits of Using an Enclosure Heat Exchanger

Energy Efficiency and Cost Savings

An enclosure heat exchanger saves energy and lowers costs. It uses smart heat pipe technology to move heat efficiently. This system cools only when needed, saving power. Unlike old systems, it doesn’t need big fans or compressors that use more electricity.

It also helps you spend less on repairs. By keeping temperatures steady, it stops overheating that can break equipment. Many modern cooling systems use eco-friendly refrigerants. These are better for the planet and improve energy use.

Tip: Pick the right cooling system to save energy and money.

Longer Equipment Life

Stable temperatures help machines last longer. Overheating can harm delicate parts and cause breakdowns. An enclosure heat exchanger keeps the temperature steady to avoid this.

For example, systems with heat pipe technology remove heat fast and well. This lowers stress on your machines, helping them work longer. By stopping extreme heat, you avoid costly repairs and keep things running smoothly.

Easy Maintenance and Dependability

Enclosure heat exchangers are strong and simple to care for. They need little maintenance, making them reliable for long use. Cleaning is easy, and they have features like dirt detection to keep working well.

The Alfa Laval Brew 701 eMotion™ is a good example. It has fewer moving parts, so it breaks less often. This also means you spend less on spare parts over time.

Service Type | What It Does |

|---|---|

Installation | Sets up the system for best performance |

Maintenance | Regular checks to keep it working well |

Repairs | Fixes problems quickly to avoid delays |

Choosing a cooling system with these features lets you focus on work without worrying about constant fixes.

Types of Enclosure Heat Exchangers

Air-to-Air Heat Exchangers

Air-to-air heat exchangers are common for cooling equipment boxes. They use two separate airflows to move heat out. Warm air inside the box passes through the exchanger. Here, it gives off heat to cooler outside air. This keeps the inside temperature steady without mixing the air.

These systems save energy and money. For example, SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Season Performance Factor) show how efficient they are. A system with a SEER of 16 cools 16,000 Btu per kWh used. This makes it a great choice for everyday needs.

Metric | What It Measures | Example |

|---|---|---|

HSPF | Heat provided per kWh during heating season. | 10.3 HSPF = 10,300 Btu/kWh |

SEER | Cooling provided per kWh during cooling season. | 16 SEER = 16,000 Btu/kWh |

Liquid-to-Air Heat Exchangers

Liquid-to-air heat exchangers use water or liquid to cool better. They take heat from the box and release it outside. This works well for big machines that make a lot of heat.

Research shows these systems cool better than older ones. For example, a TE-integrated exchanger can boost cooling by 44.9%. It can handle up to 5873.52 W of heat. This makes it perfect for tough jobs where air cooling isn’t enough.

Regular cooling: 2118.29–4241.28 W (air speeds of 10–25 m/s).

TE-integrated cooling: 3069.21–5873.52 W (44.9% better).

NEMA-Rated Models for Harsh Environments

NEMA-rated heat exchangers are made for tough conditions. They meet strict rules to block dust, water, and other dangers. For instance, a NEMA 3S rating protects against rain, snow, and ice. This makes it good for outdoor use.

NEMA Rating | What It Protects Against | IP Rating |

|---|---|---|

NEMA 1 | Indoor use, blocks dirt and contact. | IP10 |

NEMA 3S | Indoor/outdoor use, blocks rain, snow, and ice. | IP54 |

These models work well in extreme places. They keep your equipment safe and running smoothly.

Applications of Enclosure Heat Exchangers

Industrial and Manufacturing Settings

Enclosure heat exchangers are important in factories and industries. These places use big machines that create a lot of heat. Cooling units help keep the temperature just right for smooth work.

Case Study 1: Switching from old shell-and-tube exchangers to compact plate ones made heat transfer two to three times better. This change reduced the number of exchangers needed from ten to four, saving money.

Case Study 2: A refinery fixed cooling problems caused by buildup in a heat exchanger. They used a cleaning solution without stopping work, showing how reliable these systems are.

These examples show how enclosure heat exchangers boost efficiency and cut downtime in tough jobs.

Outdoor and Extreme Environments

Outdoor and harsh places need strong cooling systems. Water-to-air heat exchangers work well here. Models like NEMA 4 and NEMA 4X protect equipment from bad weather and dirt.

Did you know? Air-to-air exchangers are great in freezing weather. But they might need defrosting every hour to keep working well.

Feature | Description |

|---|---|

Installation | Simple to set up and needs little care. |

Operation | Needs clean, cold water to work best. |

Performance | Cools better than air-to-air exchangers. |

Design | Special models for tough weather conditions. |

Construction | Made with strong steel for long-lasting use. |

Water-to-air exchangers handle tough conditions, keeping equipment safe and lasting longer.

Data Centers and Electronics Enclosures

Data centers and electronics need exact temperature control to stay safe. Enclosure heat exchangers, especially with heat pipe technology, provide great cooling.

Type | Features | Applications |

|---|---|---|

Air-to-Air Exchangers | - Uses heat pipes or folded fins | Cooling cabinets, data centers |

Liquid-to-Air Exchangers | - Uses liquids with high heat transfer | MRI machines, process cooling, cabinets |

Water-to-air exchangers are perfect for places like data centers. They manage heavy heat while saving energy. These systems keep electronics safe and working well, even under pressure.

Enclosure heat exchangers help keep equipment at the right temperature. They move heat away, block outside dangers, and make machines last longer. Picking the right type—air-to-air, liquid-to-air, or NEMA-rated—gives the best results for your needs.

Pro Tip: Check what cooling your equipment needs before choosing.

Knowing their uses and benefits helps you decide better. For help, ask experts or look for more information to find the best fit for your setup.

FAQ

What does an enclosure heat exchanger do?

It keeps equipment cool by moving heat outside. This stops overheating, protects parts, and helps machines work well in different places.

How can I pick the right enclosure heat exchanger?

Think about your equipment's cooling needs and environment. For tough conditions, use NEMA-rated models. For heavy heat, liquid-to-air exchangers are better.

Tip: Ask an expert to find the best system for your needs.

Are enclosure heat exchangers good for saving energy?

Yes, they use smart tools like heat pipes and green refrigerants. These save energy and cut costs while keeping things cool.

Can I use an enclosure heat exchanger outside?

Yes, many are made for outdoor use. NEMA 4 or 4X models block rain, snow, and dust, making them great for harsh weather.

How often should I take care of an enclosure heat exchanger?

Clean filters and check for dirt every few months. Some models clean themselves, so you don’t need to do it often.

Note: Follow the maker’s rules for when to do maintenance.

See Also

Understanding Outdoor Enclosure Cabinets And Their Advantages

Exploring ESTEL Cooling Solutions For Industrial Cabinet Needs

Reliable Outdoor Enclosures: The Perfect Choice For You

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA