Why ESTEL Rectifier Cabinets Matter in Industry

In industrial settings, reliable power conversion drives efficiency and protects sensitive equipment. Rectifier cabinets play a pivotal role by transforming alternating current (AC) into direct current (DC), ensuring stable energy for critical systems.

ESTEL Rectifier Cabinets stand out due to their advanced design and proven performance. Consider these compelling facts:

Rectifier cabinets improve energy efficiency during hydrogen production, lowering operational costs for green energy initiatives.

High efficiency ratings, reaching power factors of 93%, reduce waste and optimize energy use.

Mean Time Between Failures (MTBF) exceeds 100,000 hours, ensuring dependable operation in demanding environments.

By choosing ESTEL, you gain a robust solution that safeguards your operations and supports long-term sustainability.

Key Takeaways

ESTEL Rectifier Cabinets save energy and lower costs in industries.

They are very efficient, with up to 97.83% energy savings.

Strong designs handle tough conditions, giving steady power for industries.

Custom designs help meet special power needs for better performance.

Safety features protect machines from voltage changes, making them last longer.

Understanding Rectifier Cabinets

What Is a Rectifier Cabinet?

A rectifier cabinet is a specialized electrical enclosure designed to convert alternating current (AC) into direct current (DC). This conversion is essential for powering systems that rely on DC, such as industrial machinery, telecommunications equipment, and energy storage solutions. The cabinet houses components like rectifiers, transformers, and control systems, all working together to ensure stable and efficient power delivery.

Modern rectifier cabinets incorporate advanced features to enhance their functionality. For example, modular microprocessor controls monitor and manage operations, ensuring optimal performance. Protective mechanisms, such as overvoltage and overheating safeguards, maintain reliability and safety. These features make rectifier cabinets indispensable in environments where uninterrupted power is critical.

Importance of Rectifier Cabinets in Industrial Applications

Rectifier cabinets play a vital role in industrial applications by ensuring consistent and reliable power conversion. Many industries depend on DC power for their operations, and rectifier cabinets provide the necessary infrastructure to meet these demands. Without them, systems like manufacturing automation, telecommunications networks, and energy management platforms would face inefficiencies and potential downtime.

In industrial settings, performance standards and specifications are crucial for evaluating rectifier cabinets. These standards ensure that the cabinets meet reliability, noise level, and manufacturing criteria. For instance:

Standard/Specification | Description |

|---|---|

RUS performance specification for line concentrators, including noise level requirements and reliability criteria. | |

ANSI S1.4-1983 | Specification for Sound Level Meters, relevant for measuring noise from rectifiers. |

ASTM B33-91 | Standard Specifications for Tinned Soft or Annealed Copper Wire for Electrical Purposes. |

These guidelines help manufacturers design rectifier cabinets that align with industry needs, ensuring their suitability for demanding applications.

Rectifier cabinets also contribute to energy efficiency by minimizing power losses during conversion. This efficiency reduces operational costs and supports sustainable practices. In addition, their robust design allows them to operate in harsh environments, making them ideal for industries like power generation and telecommunications.

Tip: When selecting a rectifier cabinet for your industrial application, prioritize models with modular designs and advanced protective features. These ensure long-term reliability and adaptability to changing operational needs.

Features of ESTEL Rectifier Cabinets

Advanced Technology for Power Conversion

ESTEL rectifier cabinets utilize cutting-edge rectifier technologies to achieve high conversion efficiency. These systems excel at transforming AC to DC with minimal energy loss, ensuring clean power delivery for your operations. The advanced design incorporates modular components, allowing you to scale the system based on your specific needs. This scalability ensures that your dc rectifier system can adapt to growing energy demands without compromising performance.

The high efficiency of ESTEL rectifiers also reduces operational costs. By minimizing power losses during conversion, these systems support sustainability goals while maintaining reliable power delivery. Whether you operate in manufacturing, telecommunications, or renewable energy, the advanced technology in ESTEL rectifiers ensures consistent power quality and system reliability.

Durability in Harsh Industrial Environments

Industrial environments often expose equipment to extreme conditions, including high temperatures, dust, and humidity. ESTEL rectifier cabinets are designed to withstand these challenges. Their robust construction and high-quality materials ensure long-term durability, even in the most demanding settings. For high-current applications, these cabinets maintain stable performance, protecting your systems from potential damage.

The cabinets also feature advanced cooling mechanisms to prevent overheating, ensuring uninterrupted operation. This durability makes them ideal for industries like power generation and data centers, where reliability is critical. By choosing ESTEL, you invest in a solution that guarantees consistent performance and protects your equipment from environmental stressors.

Customization for Specific Applications

Every industry has unique power requirements, and ESTEL rectifier cabinets offer the flexibility to meet them. These systems can be customized to suit specific applications, ensuring optimal performance and efficiency. For example, in renewable energy projects, customized rectifiers enhance the performance of intermittent power sources like solar and wind. Germany’s Energiepark Mainz uses advanced rectifiers for a 6 MW PEM electrolyzer, demonstrating the adaptability of ESTEL’s design.

In hydrogen refueling stations, modular electrolysers with high-efficiency rectifiers maintain strict voltage tolerances. California’s stations rely on these systems to ensure reliable power delivery. Similarly, data centers benefit from high-density rectifiers like the TDM2254xD series, which optimize space and energy consumption. These examples highlight how ESTEL rectifier cabinets provide tailored solutions for diverse industries.

Note: Customization ensures that your dc rectifier system aligns with your operational goals, delivering high conversion efficiency and supporting long-term sustainability.

Benefits of ESTEL Rectifier Cabinets

Protecting Industrial Equipment

Industrial equipment requires consistent and stable power to function effectively. ESTEL rectifier cabinets excel at providing reliable power delivery, safeguarding your systems from potential damage caused by voltage fluctuations or power surges. Their advanced protection mechanisms, such as overvoltage and short circuit safeguards, ensure uninterrupted power delivery. This feature is critical in industrial applications where even minor disruptions can lead to costly downtime or equipment failure.

The robust design of these rectifiers also minimizes the risk of overheating. Advanced cooling systems maintain optimal operating temperatures, even in high-current applications. This ensures that your equipment remains protected, regardless of the environmental conditions. By investing in ESTEL rectifier cabinets, you secure the longevity and reliability of your industrial systems.

Tip: Regular maintenance of your rectifier cabinet further enhances its protective capabilities, ensuring long-term operational stability.

Enhancing Energy Efficiency

Energy efficiency is a top priority in modern industrial applications. ESTEL rectifier cabinets are designed to maximize efficiency, reducing energy waste and operational costs. These systems achieve peak efficiency levels of 97.83%, with full load efficiency consistently exceeding 96%. This high efficiency minimizes power losses during ac to dc conversion, ensuring clean power delivery to your equipment.

Metric | Value |

|---|---|

Peak Efficiency | 97.83% |

Full Load Efficiency (min) | Above target |

Energy Efficiency Levels | Exceeding 96% |

The advanced rectifier technologies used in ESTEL cabinets also contribute to sustainability by lowering energy consumption. This makes them an ideal choice for industries aiming to reduce their carbon footprint. Whether you operate in manufacturing, telecommunications, or renewable energy, these rectifiers provide a cost-effective solution that aligns with your energy efficiency goals.

Extending System Longevity

The durability and advanced features of ESTEL rectifier cabinets significantly extend the lifespan of your dc rectifier system. These cabinets incorporate hot-swappable modules, allowing you to replace components without disrupting operations. This feature minimizes downtime and ensures continuous power delivery, even during maintenance.

Additionally, the high efficiency of these rectifiers reduces energy loss and heat generation. Lower heat levels decrease the strain on cooling systems, further extending the lifespan of your equipment. Advanced protection mechanisms also shield your system from voltage fluctuations and short circuits, ensuring long-term reliability.

Advanced protection mechanisms safeguard against voltage fluctuations and short circuits.

Hot-swappable modules enable quick replacements, reducing downtime.

High efficiency reduces energy loss and heat generation, lowering cooling requirements.

By choosing ESTEL rectifier cabinets, you invest in a solution that not only meets your current needs but also supports the long-term sustainability of your operations.

Note: Proactive monitoring of your rectifier system can help identify potential issues early, ensuring optimal performance and extended longevity.

Applications of Rectifier Cabinets in Industry

Power Plants and Energy Management

In power plants, rectifier cabinets play a critical role in ensuring reliable energy conversion. These systems transform AC into DC, enabling efficient operation of equipment like battery storage units and control systems. High-current applications, such as hydrogen production, benefit from the high efficiency of modern rectifier technologies. By minimizing energy losses, these cabinets support energy efficiency goals and reduce operational costs.

Renewable energy projects also rely heavily on rectifier cabinets. Solar inverters, for instance, depend on these systems to convert energy from photovoltaic cells into usable DC power. This ensures consistent power quality, even when energy generation fluctuates. The scalability of rectifier cabinets allows you to adapt to growing energy demands, making them indispensable in both traditional and renewable energy sectors.

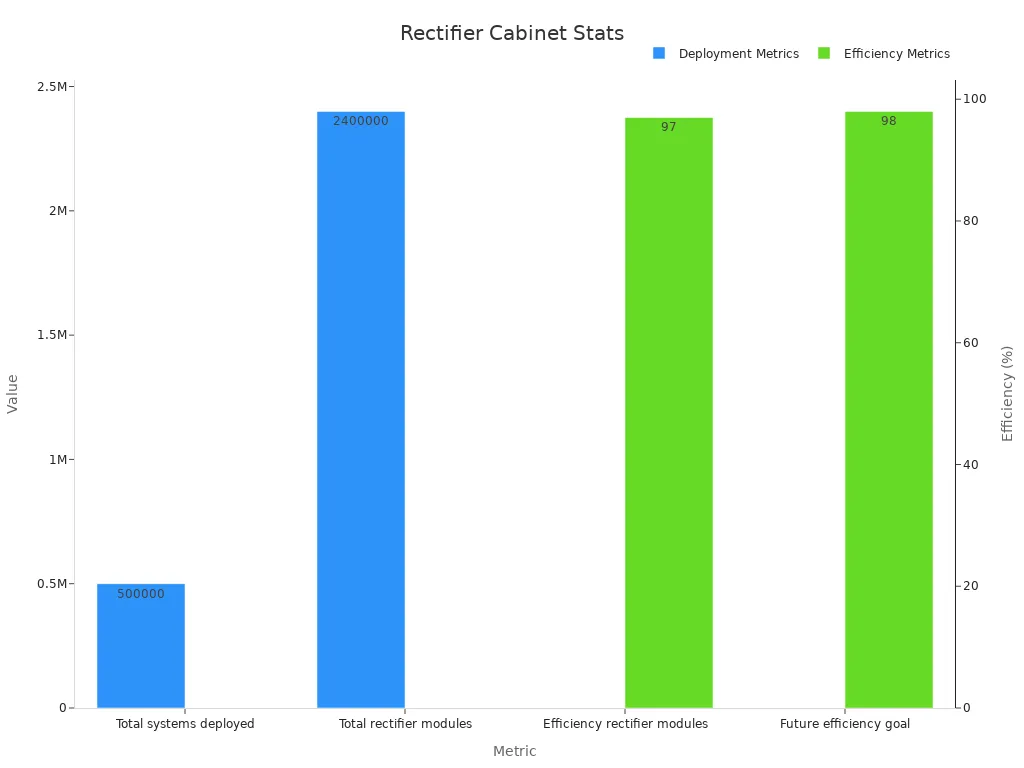

Telecommunications and Data Centers

Telecommunications and data centers demand uninterrupted power to maintain service stability. Rectifier cabinets provide the backbone for these operations by delivering consistent DC power. The expansion of 5G networks has further increased the need for robust power solutions. With efficiency ratings nearing 97%, these systems save energy while ensuring optimal performance.

Metric | Value |

|---|---|

Total systems deployed | 500,000 |

Total rectifier modules | 2,400,000 |

Efficiency of rectifier modules | Near 97% |

Future efficiency goal | Near 98% |

Data centers benefit from the modular design of rectifier cabinets, which simplifies maintenance and reduces downtime. Advanced rectifier technologies adjust power output to match demand, ensuring energy efficiency and cost-effectiveness. These features make rectifier cabinets a cornerstone of modern telecommunications and data infrastructure.

Manufacturing and Automation Systems

In manufacturing and automation, rectifier cabinets ensure reliable power delivery for critical processes. Industries like aerospace and mining have successfully integrated these systems to enhance operational efficiency. For example, anodizing rectifiers in aerospace manufacturing replaced outdated equipment, improving reliability and reducing downtime. Similarly, mining operations have upgraded shovel drive systems and mine hoist controls, achieving significant productivity gains.

The adoption of smart technologies in industrial applications has further increased the demand for rectifier cabinets. These systems provide stable DC power for automated machinery, ensuring consistent performance. Their robust design and high efficiency make them ideal for high-current applications, where reliability is paramount. By investing in a dc rectifier system, you can enhance energy efficiency and extend the lifespan of your equipment.

Tip: Choose rectifier cabinets with advanced cooling mechanisms to ensure optimal performance in high-demand environments.

ESTEL Rectifier Cabinets play a vital role in industrial applications by delivering reliable power conversion and protecting critical systems. Their advanced technology ensures efficiency, durability, and adaptability across diverse industries. These cabinets reduce outages by up to 40% and restore power 50% faster, while improving power quality issue identification by 80%.

Metric | Improvement Range |

|---|---|

Reduction in outage minutes | 20-40% |

Faster outage restoration | 40-50% |

Reduction in momentary interruptions | 25-35% |

Improvement in power quality issue identification | 60-80% |

By choosing ESTEL, you invest in a solution that enhances operational efficiency, reduces costs, and ensures long-term reliability.

FAQ

What makes ESTEL Rectifier Cabinets different from other brands?

ESTEL Rectifier Cabinets stand out due to their high efficiency, modular design, and advanced protective features. They offer peak efficiency levels of up to 97.83%, ensuring minimal energy loss. Their durability and customization options make them suitable for diverse industrial applications.

Can ESTEL Rectifier Cabinets handle extreme environmental conditions?

Yes, ESTEL Rectifier Cabinets are built for harsh environments. Their robust construction, advanced cooling systems, and high-quality materials ensure reliable performance in extreme temperatures, dust, and humidity. These features make them ideal for industries like mining, power generation, and telecommunications.

How do ESTEL Rectifier Cabinets improve energy efficiency?

These cabinets achieve energy efficiency by minimizing power losses during AC to DC conversion. With full load efficiency exceeding 96%, they reduce operational costs and support sustainability goals. Their advanced rectifier technologies ensure clean power delivery, making them a cost-effective solution for energy-conscious industries.

Are ESTEL Rectifier Cabinets customizable for specific needs?

Absolutely! ESTEL offers customization options to meet unique industrial requirements. Whether you need rectifiers for renewable energy projects, hydrogen refueling stations, or data centers, ESTEL can tailor their systems to optimize performance and efficiency for your application.

How do ESTEL Rectifier Cabinets protect industrial equipment?

These cabinets safeguard equipment with advanced protection mechanisms like overvoltage, short circuit, and overheating safeguards. Their stable power delivery prevents disruptions, ensuring the longevity of your systems. Hot-swappable modules also allow quick replacements, minimizing downtime and maintaining operational stability.

Tip: Regular maintenance enhances the protective capabilities of your rectifier cabinet, ensuring long-term reliability.

See Also

Ensuring Correct Voltage Levels in ESTEL Communication Cabinets

Exploring ESTEL's Cooling Solutions for Industrial Cabinet Needs

Telecom Cabinets Powered by ESTEL Energy Storage Batteries

Understanding ESTEL PDUs and Their Importance in Data Centers

CALL US DIRECTLY

86-13752765943

3A-8, SHUIWAN 1979 SQUARE (PHASE II), NO.111, TAIZI ROAD,SHUIWAN COMMUNITY, ZHAOSHANG STREET, NANSHAN DISTRICT, SHENZHEN, GUANGDONG, CHINA